Multifunctional shaft detection device and detection method

A detection device and detection method technology, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve problems such as laborious, indeterminate wellbore external corrosion, and low wellbore requirements, so as to improve efficiency and safety performance, improve investment efficiency and return rate, and detect the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0067] The implementation steps of the specific method are as follows:

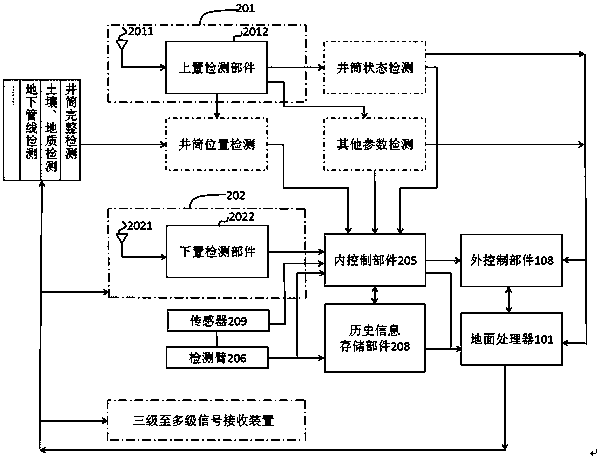

[0068] When the detected information needs to be stored, the information is stored in the historical information storage unit 208 through the internal control unit 205 and the external control unit 108 , or the detected electrical signal is converted into an optical signal by optical fiber and then transmitted to the ground processor 101 .

[0069] After the detection of the required wellbore information is completed, the built-in multifunctional wellbore detection device 2 is lifted out of the wellbore, and then its historical information storage unit 208 is connected to the information interpretation equipment, such as the surface processor 101 interface to import, save and read the detection information .

Embodiment 3

[0071] The specific method implementation steps are as follows: remote intelligent remote control type

[0072] The ground controller can be connected to the local computer to read the detection information, and can also be connected to the remote computer through a wired or wireless data link. It can operate without any management on site. The operator only needs to remotely receive and send control information to realize the controller To manage and ensure the normal operation of the detection device, it can realize both local operation and remote intelligent operation, and has the advantages of reducing labor costs, multi-functional processing, and convenient control.

[0073] The invention can quantitatively analyze the detected incomplete defects of the wellbore, improve the detection efficiency and operation accuracy of the wellbore, effectively provide guidance and reference for oil and gas wells to carry out workover or secondary completion operations, and make oil and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com