Device and method for evaluating capillary force in water injection process of oil reservoir

A capillary force and oil reservoir technology, which is applied in the direction of earthwork drilling, fluid extraction, and undisturbed core extraction devices, can solve problems such as limited measurement range, testing capillary force, and affecting fluid distribution in the core, and achieves the goal of weakening the liquid end effect Impact, error reduction, targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

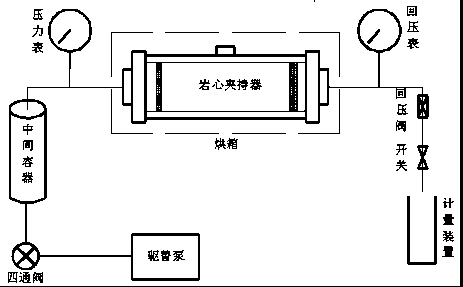

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

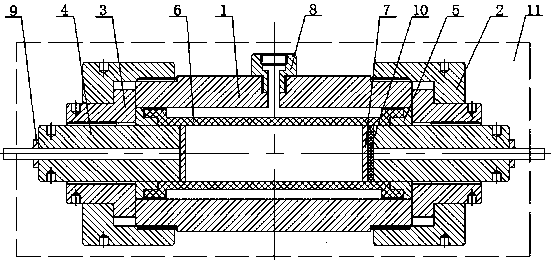

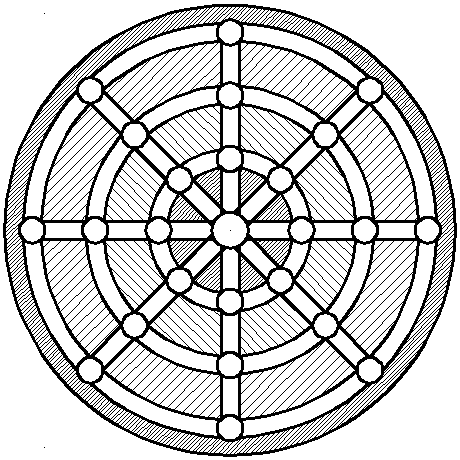

[0019] Such as figure 1 As shown, the core holder consists of a cylinder body 1, a sealing pressure cap 2, a plug 3, a core plug 4, a tapered sleeve 5, a rubber sleeve 6, a high-permeability metal partition 7, a ring pressure joint 8, and a pipeline fixing joint 9 , screen 10 and oven 11.

[0020] There is a rubber sleeve 6 inside the cylinder body 1, and the rock core to be tested can be placed in the rubber sleeve 6. The fixed ring pressure joint 8 is connected to the outside of the cylinder body 1, the central hole of the ring pressure joint 8 communicates with the inside of the cylinder body 1, the top of the ring pressure joint 8 can be connected to the pipeline, and the pipeline is connected to the confining pressure pump, and the core can be applied to the core through the confining pressure pump. Confining pressure.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com