Drying mechanical device

A mechanical device and drying technology, which is applied in the direction of progressive dryers, drying gas layout, dryers, etc., can solve the problems of high drying operation costs, failure to meet energy conservation and environmental protection, and deterioration of the drying workshop environment, and achieve optimal equipment Structure and control method, improvement of energy utilization efficiency, effect of improvement of drying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

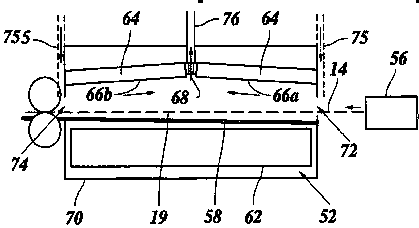

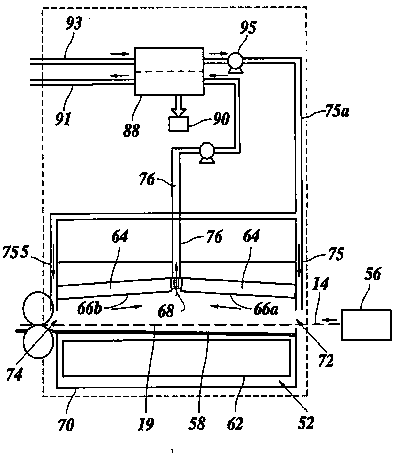

[0019] like figure 1 As shown, the drying mechanical device of the present invention includes a fixing device 52, a heating device 62, a horizontal conveyor belt 19, a feed bin 56, a water vapor collection cover 64, a water vapor collection pipe 76 and a condenser 88, wherein the fixed The device 52 includes a housing 70, and the heating device 62 is arranged inside the housing 70; the horizontal conveyor belt 19 is arranged directly above the housing 70, and one end of the horizontal conveyor belt 19 is positioned in the feeding bin 56, and the feeding bin 56 is provided with materials waiting to be dried, and the horizontal conveyor belt 19 is used to transport the materials waiting to be dried in the feed bin 56 from one side of the housing 70 to the other side of the housing 70. The material 14 waiting to be dried is heated and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com