Hydraulic cylinder leakage analysis diagnosis method

A diagnostic method and hydraulic cylinder technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, fluid tightness test, machine/structural component test, etc., can solve inconvenient installation, large leakage difference, Complex system structure and other problems, to achieve the effect of strong convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

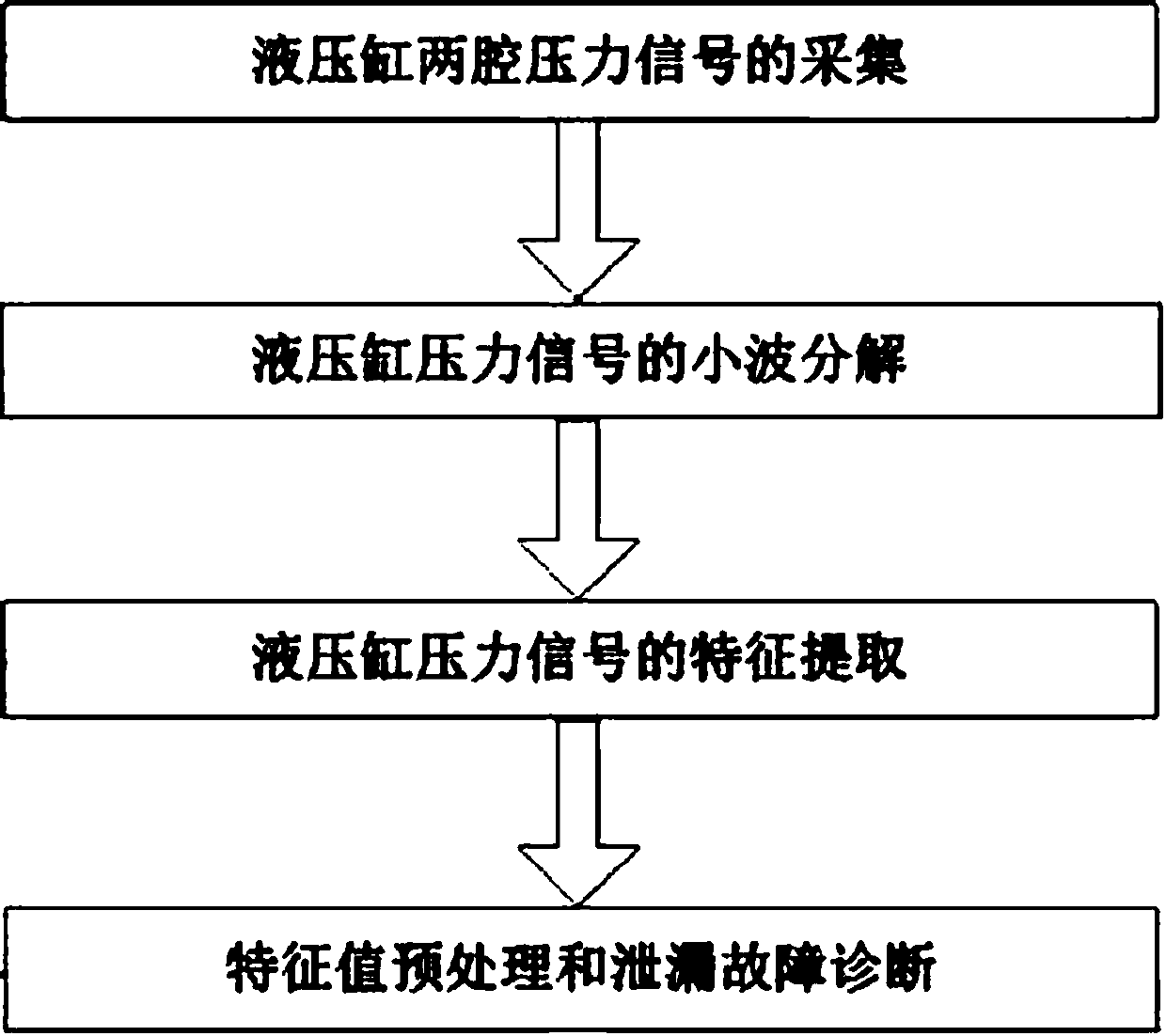

[0033] The present invention provides a diagnostic method for hydraulic cylinder leakage analysis, such as figure 1 shown, including the following steps:

[0034] Step S1: Collect the pressure signals of the two chambers of the hydraulic cylinder, perform wavelet analysis on them and extract the characteristic values of the corresponding pressure time-frequency signals to construct a sample data set;

[0035] Step S2: Use the sample data set to perform wavelet coefficient preprocessing, calculate the root mean square value and root mean square error and standardize them, and compare with the preset threshold signal to realize the identification and diagnosis of the small leakage of the hydraulic cylinder.

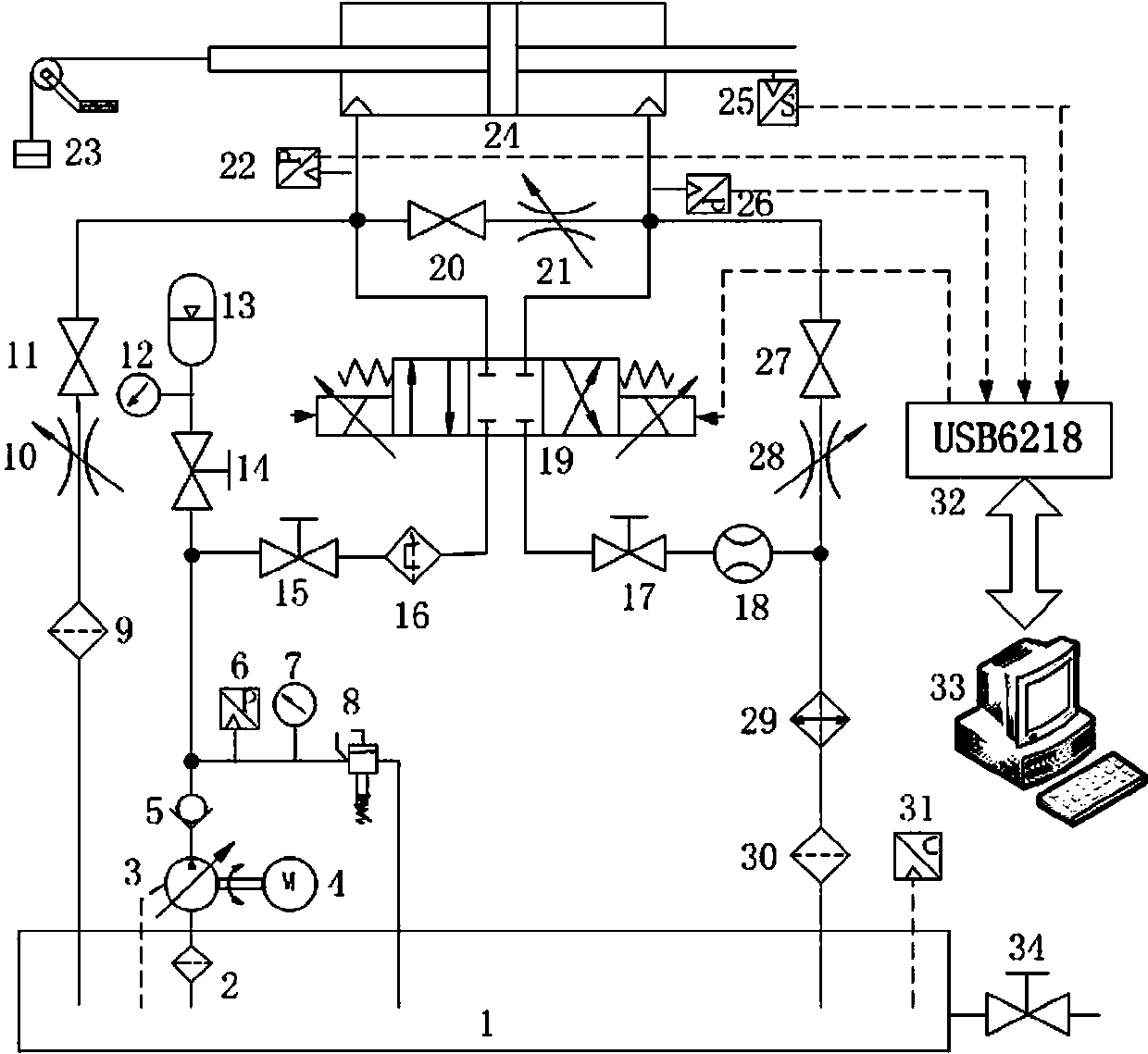

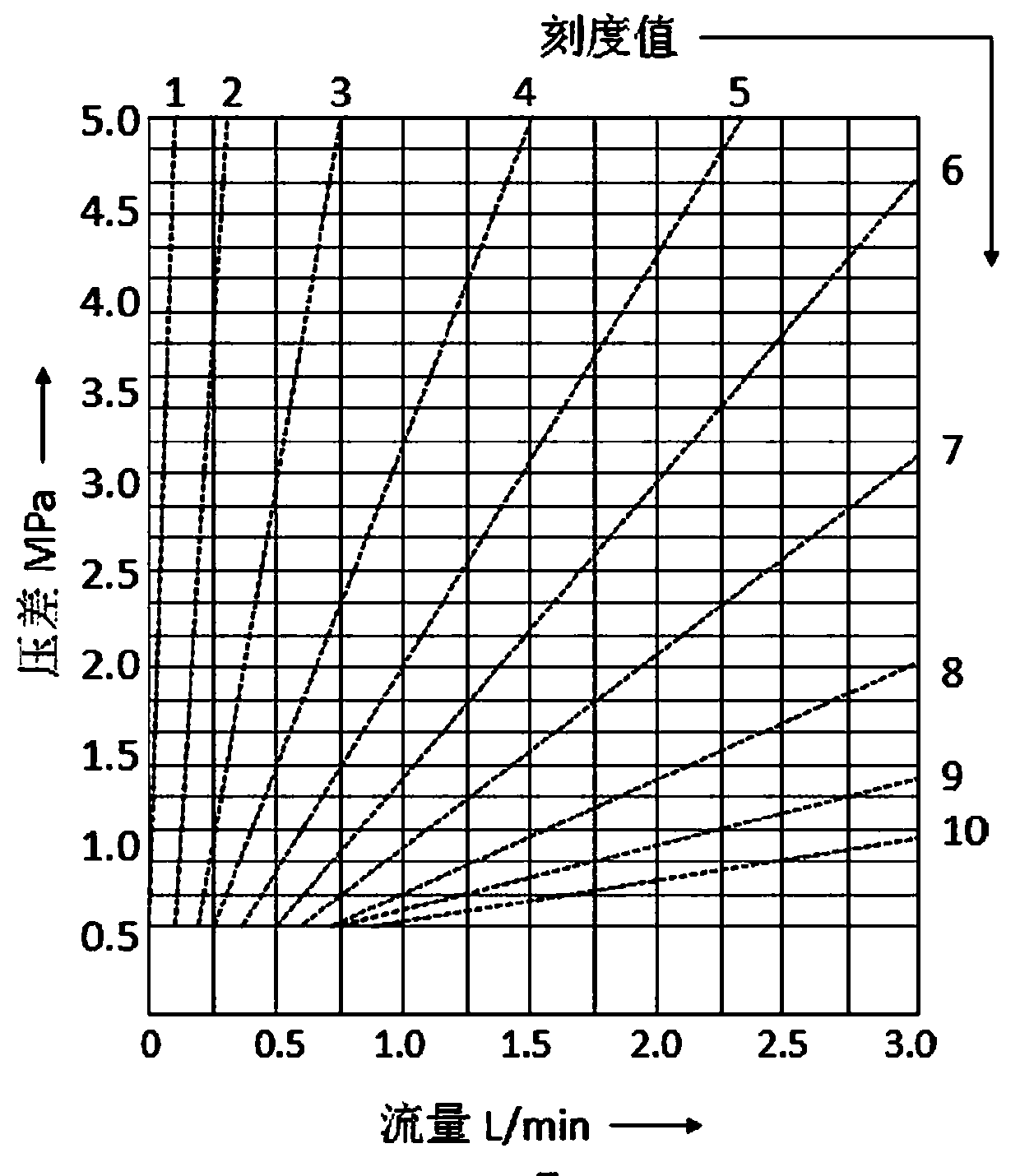

[0036] In this embodiment, the two-chamber pressure signal of the hydraulic cylinder is collected as the input of the leakage faul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com