Sample inserting equipment for deep-layer grains of grain granary

A technology for grain and cutting samples, applied in sampling, sampling devices, measuring devices, etc., can solve the problems of difficult operation, cumbersome, high work intensity, etc., and achieve the effect of simple use and maintenance, reasonable operation mode, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

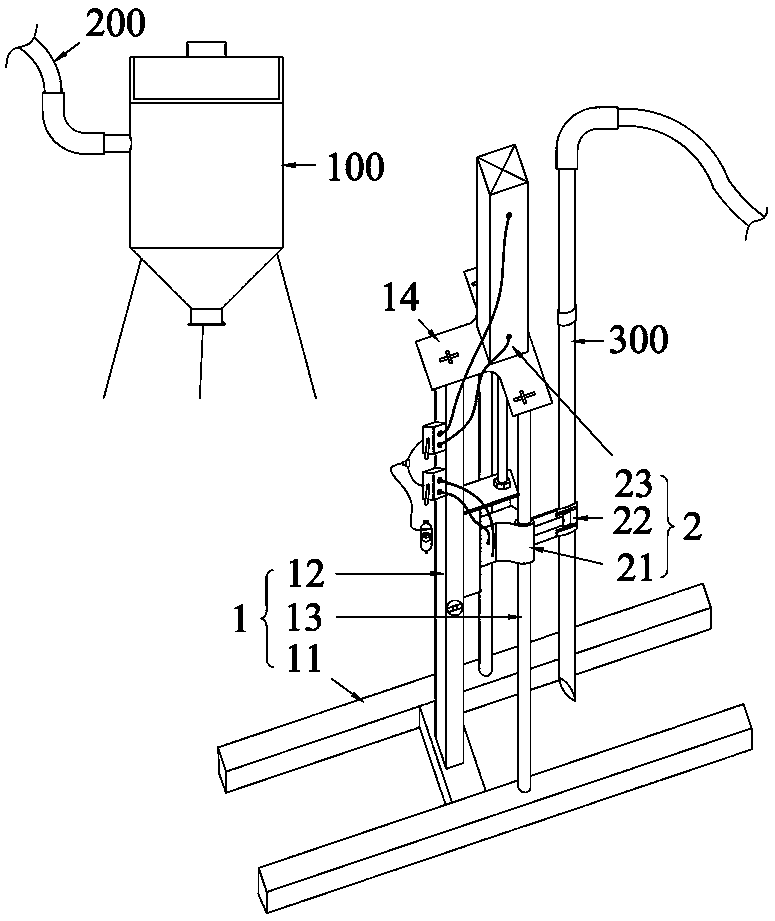

[0031] refer to figure 1 with Figure 5 As shown, the present embodiment provides a kind of deep-layer grain sampling equipment for grain warehouses, which is configured to realize the mechanized operation of sampling deep-layer grain in large-scale grain warehouses, including for placing on the top surface of grain piles without bottoming The sinking support mechanism 1 is set in the support mechanism 1 to form the vertical lifting movement part, and enables the sample pipe fitting 300 to sink vertically to the sample pipe connection and unloading mechanism 2 in the grain pile, and controls the connection and unloading of the sample pipe Mechanism 2 realizes the control system of subsidence work. The sample tube connecting and unloading mechanism 2 is an executive mechanism driven by a power source. According to actual operation requirements, the sample tube connecting and unloading mechanism 2 is controlled by the control system to sink the sample tube 300 into the grain pi...

Embodiment 2

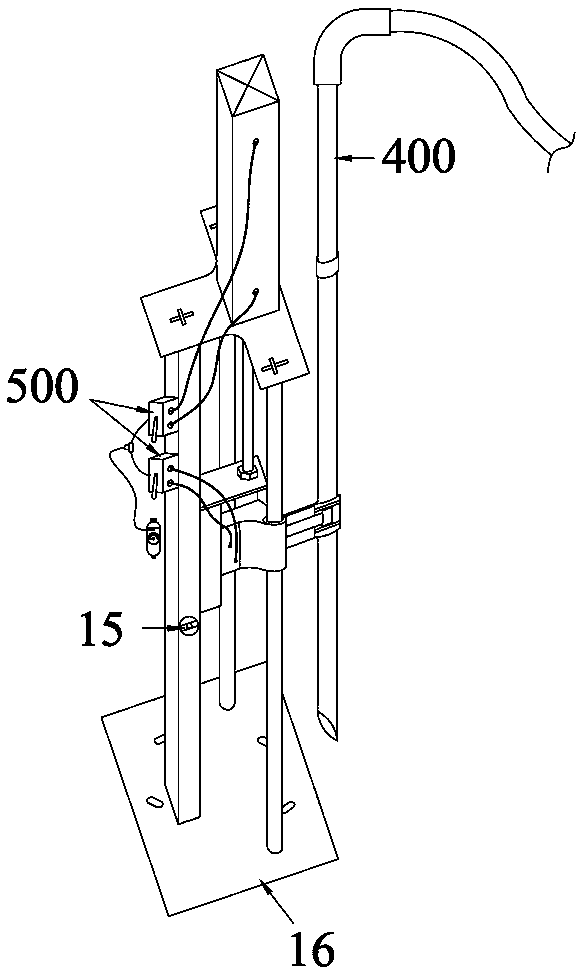

[0043] Embodiment 2 of the present invention proposes a deep-layer grain-sampling device in a grain warehouse, including the deep-layer grain-sampling device in a grain warehouse shown in Embodiment 1.

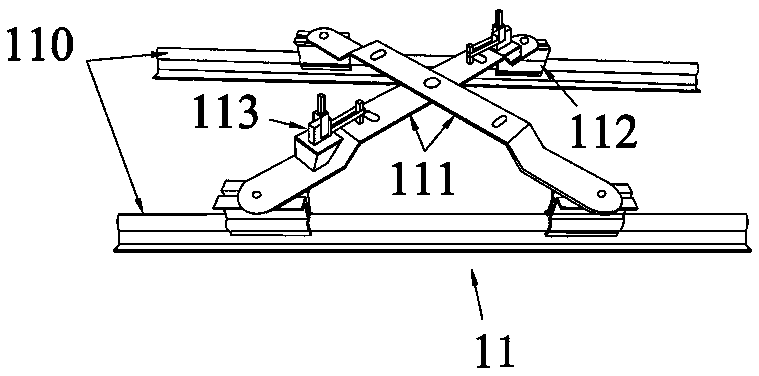

[0044] The difference is that the reference Figure 2 to Figure 4 As shown, the base part 11 is a split structure, including an embedded support 17 with a screw structure and a folding base. In the embedded part of the state, the top plate 171 is provided with a connecting structure adapted to the assembly of the folding base, and corresponding to the position of the clamping claw 220, a sample rod is provided on the top plate 171. The through hole through which the member 300 passes. Preferably, the connection structure is a quick clamp 113, which provides convenience for assembly and firm connection.

[0045] Preferably, the embedded part is an auger structure 170, which is used to vertically drill into the grain pile and use the internal pressure of the grain pile for sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com