Acoustic emission source locating method and system used for rock mechanics triaxial test

An acoustic emission source, triaxial test technology, which is applied in the direction of using acoustic emission technology for material analysis, processing the response signal of detection, etc. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

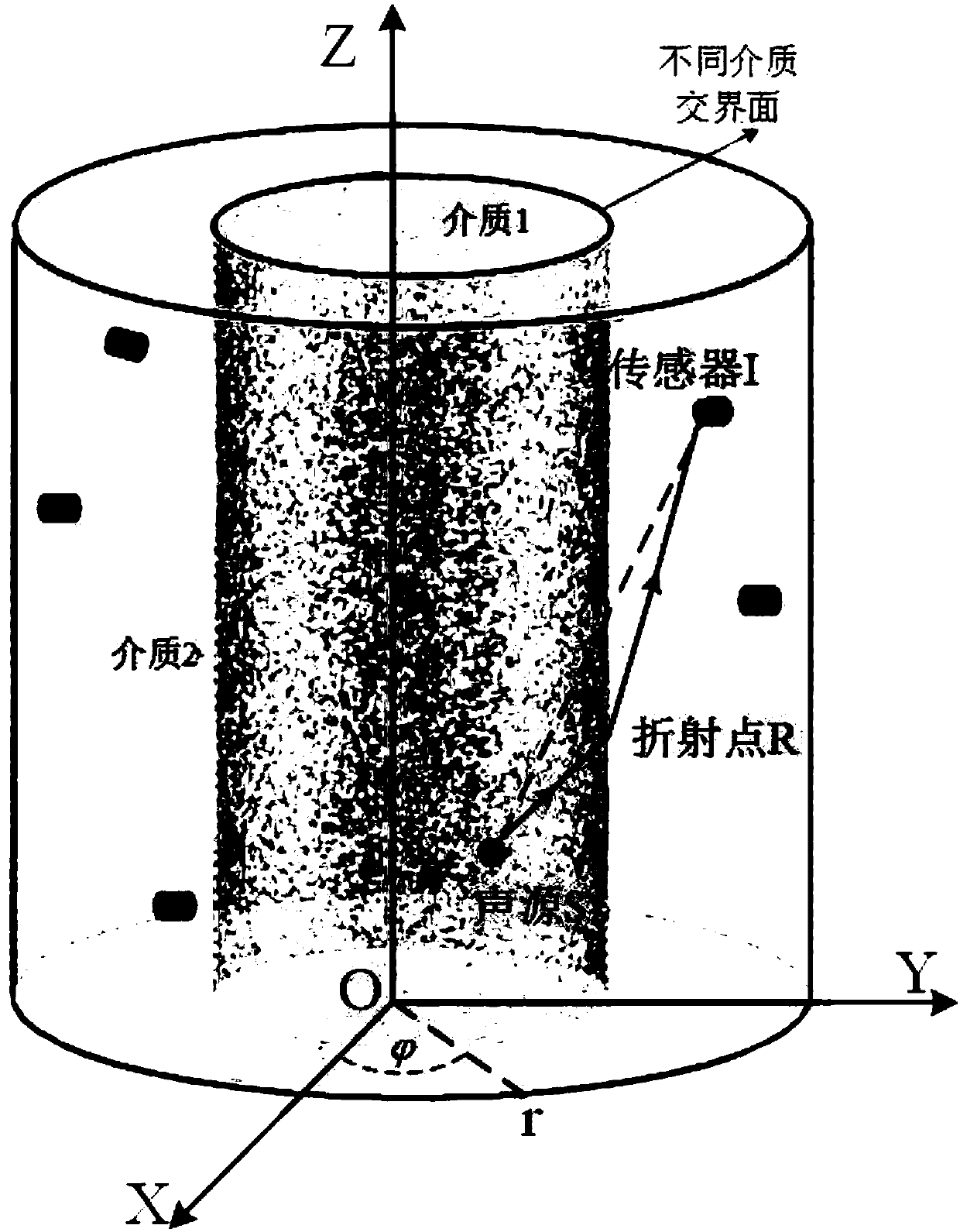

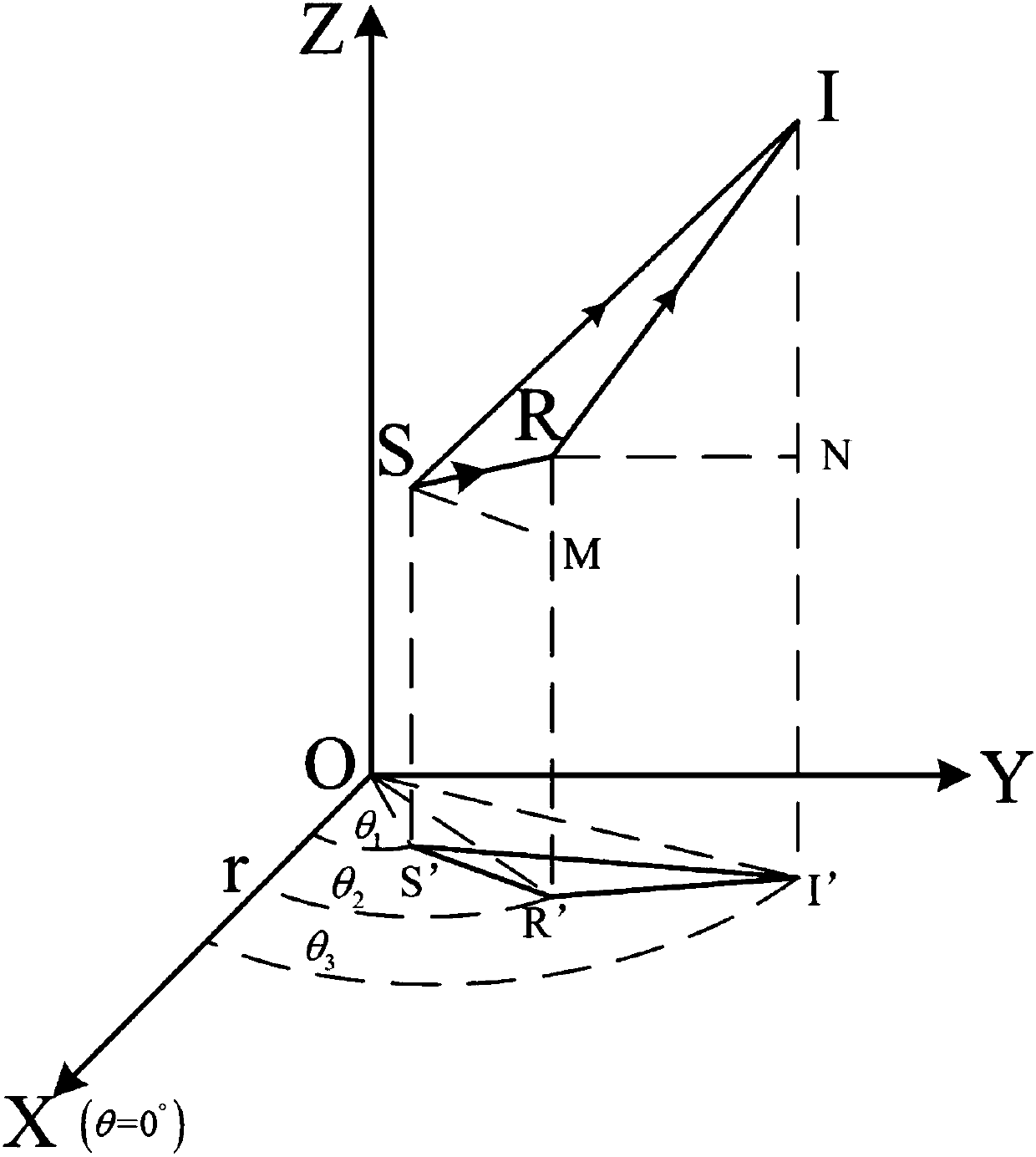

[0032] Such as figure 2 The simplified two-layer curved surface medium model of the rock mechanics triaxial test shown, S is the sound source point generated by the rupture of the internal rock medium, and the wave velocity of the medium is C 1 , S is the acoustic emission sensor located on the medium surface of the outer cylinder, and the wave velocity of the medium is C 2 , an acoustic emission signal is generated at the sound source point S, propagates along a straight line to the interface of the two media for refraction, and then continues to propagate along a straight line to the acoustic emission sensor I, where the signal is received.

[0033] Assuming that in the cylindrical coordinate system, its coordinates are S(θ 0 ,r 0 ,h 0 ), R(θ ri ,r ri ,h ri ), I(θ i ,r i ,h i ), you can get

[0034]

[0035]

[0036] The distance between the sound source S and the corresponding refraction point R is

[0037]

[0038] The distance between the sensor I and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com