Novel glass fiber reinforced plastic lightning rod

A lightning rod and fiberglass technology, which is applied in the direction of circuits, corona discharge devices, electrical components, etc., can solve the problems of large investment in the production of fiberglass lightning rods, the difficulty of applying lightning rods to other places, and the impact of lightning rod installation schedules, etc., to ensure lightning protection and conduction Performance, assembly flexibility, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

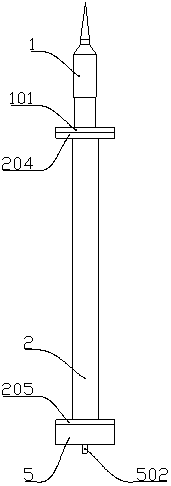

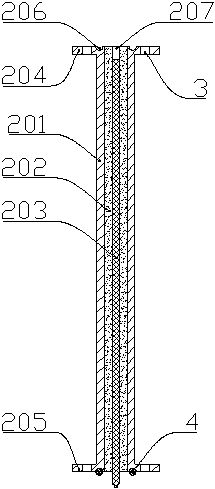

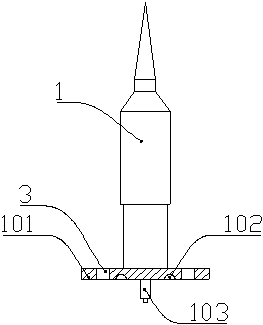

[0031] see Figure 1-4 As shown, a new type of FRP lightning rod includes a rod body, a lightning rod 1 fixed on the top of the rod body, and a base 5 fixed on the lower end of the rod body. Outer cladding 201, filling layer 202 and copper bar 203 made of FRP material, the upper end of the outer cladding 201 is provided with a first flange piece 204, the lower end of the outer cladding 201 is provided with a second flange piece 205, the first method The end faces of the blue piece 204 and the second flange piece 205 are provided with a first annular groove 206; the inner filling layer 202 is filled between the outer cladding layer 201 and the copper row 203; the lower end of the lightning rod 1 is provided with a second Three flanges 101, the end surface of the third flange 101 is provided with a second annular groove 102 corresponding to the first annular groove 206, and the middle part of the lower end of the lightning rod 1 is provided with a down conductor 103; A third an...

Embodiment 2

[0035] see Figure 2-6, a new type of fiberglass lightning rod, including a rod body, a lightning rod 1 fixed at the top of the rod body, and a base 5 fixed at the lower end of the rod body, the rod body is formed by detachably connecting two holding rods 2, and the holding rod 2 includes The outer cladding 201, the filling layer 202 and the copper bar 203 made of high-strength composite glass fiber reinforced plastics, the upper end of the outer cladding 201 is provided with a first flange piece 204, and the lower end of the outer cladding 201 is provided with a second flange piece 205. The end faces of the first flange piece 204 and the second flange piece 205 are provided with a first annular groove 206; the inner filling layer 202 is filled between the outer cladding layer 201 and the copper bar 203; the lower end of the lightning rod 1 A third flange piece 101 is provided, the end surface of the third flange piece 101 is provided with a second annular groove 102 correspon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com