Multi-segment control coil wire winding structure of electromagnetic heating appliance and electromagnetic heating appliance

A winding structure and coil control technology, which is applied in the direction of induction heating control, electric/magnetic/electromagnetic heating, induction heating, etc., can solve the problem that the heating wire power cannot be intelligently adjusted, the effect of rice cooking is not greatly improved, and the life of the rice cooker is short, etc. problem, to achieve the effect of saving assembly space, good cooking effect, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

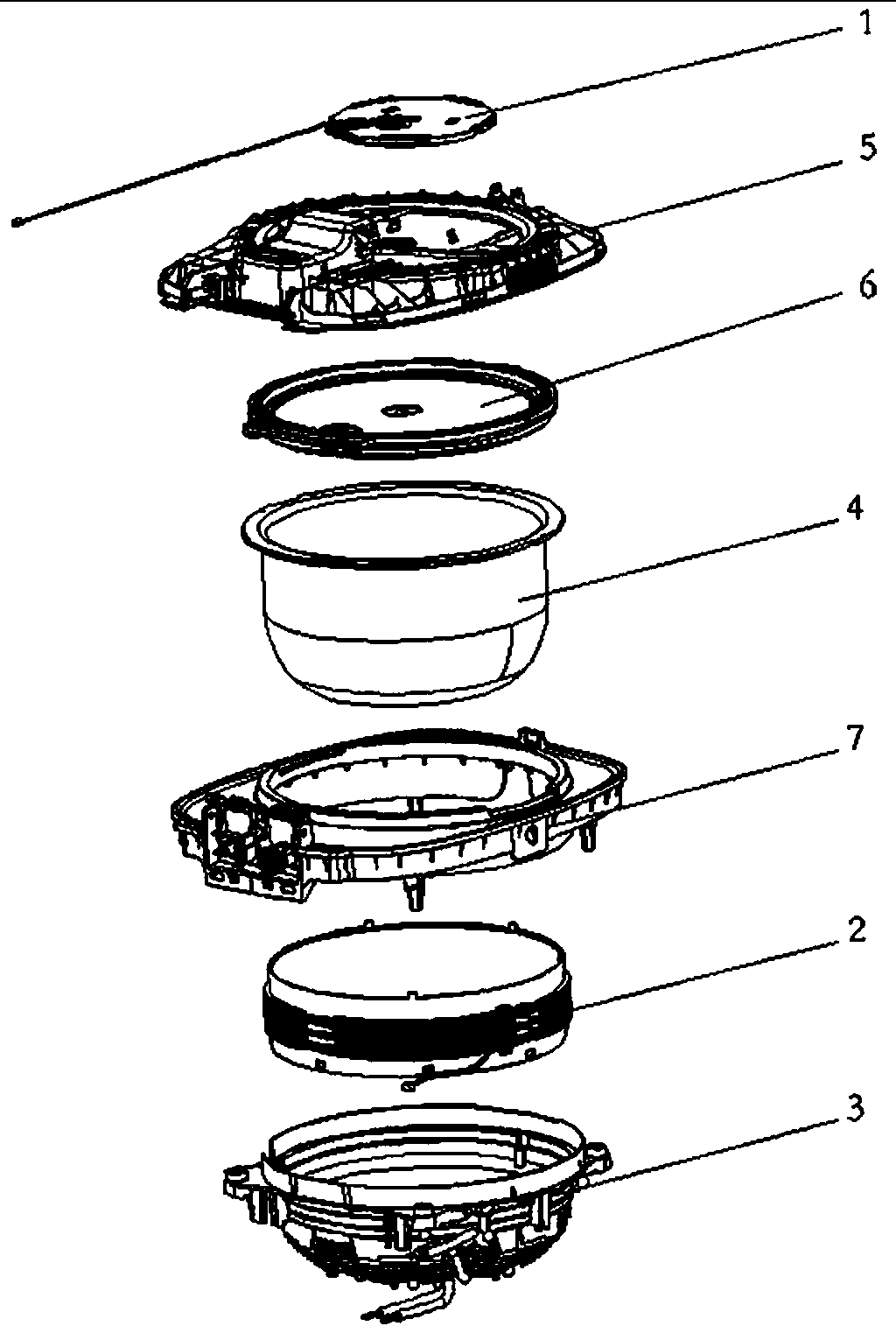

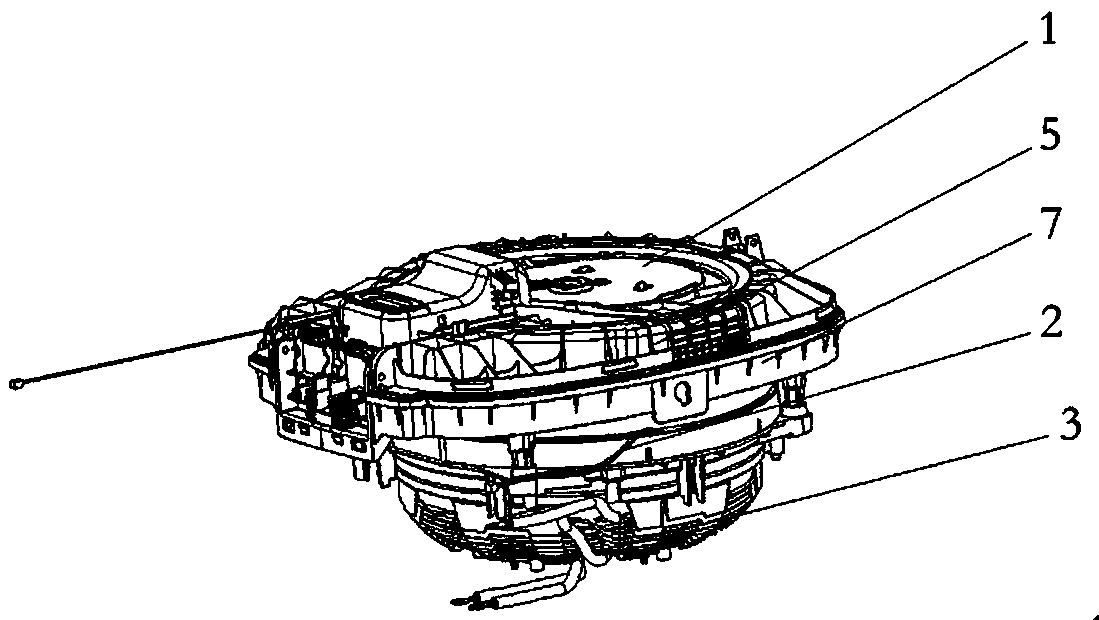

[0044] Such as figure 1 , 2 As shown, the preferred embodiment of the present invention proposes a multi-section control coil winding structure, including: top winding reel assembly 1, side winding reel assembly 2 and bottom winding reel assembly 3, top winding reel assembly 1 It is arranged on the top surface of the inner pot 4 , the side winding disc assembly 2 is set on the side outer ring of the inner pot 4 , and the bottom winding disc assembly 3 is arranged on the bottom of the inner pot 4 .

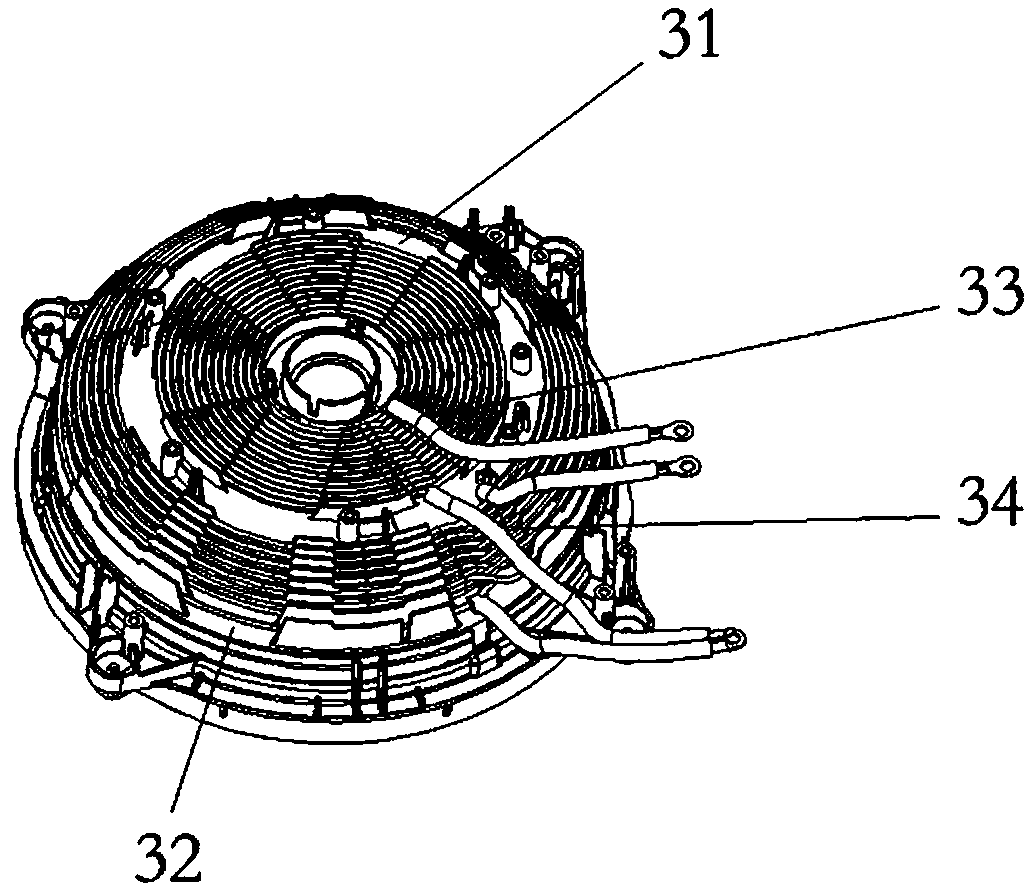

[0045] Such as image 3 As shown, the bottom winding reel assembly 3 includes: a bottom winding support 31, an R angle winding support 32, a bottom coil 33 wound on the bottom winding support 31, an R angle coil wound on the R angle winding support 32 34. The bottom winding bracket 31 is arranged in a flat plate under the bottom surface of the inner pot 4. The R-angle winding bracket 32 is arranged on the edge of the bottom winding bracket 31 and extends along the arc of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com