Method for improving laser melting deposition forming quality

A technology of laser melting deposition and forming quality, applied in the field of additive manufacturing, can solve the problems of deposition quality and performance degradation, and achieve the effect of improving process stability and processing quality, simple and easy operation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

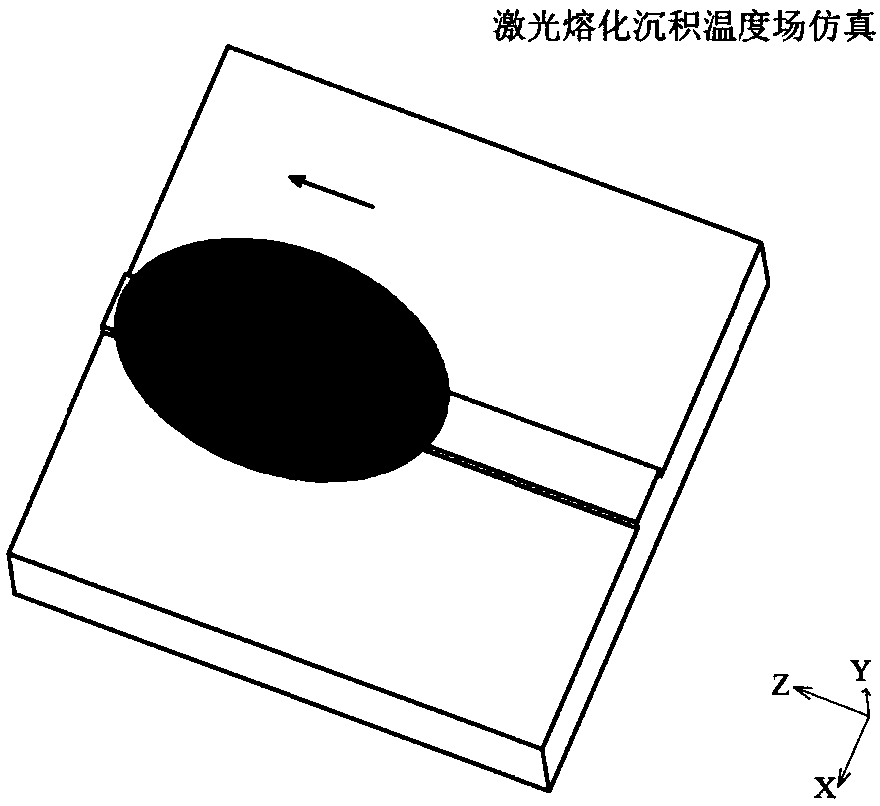

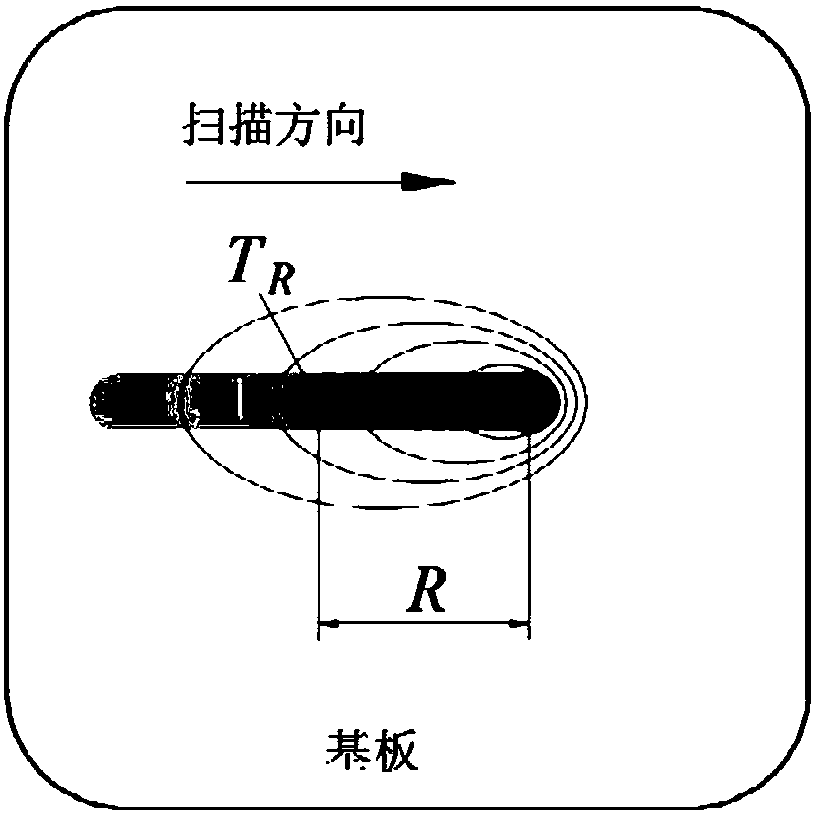

[0028] Such as Figure 1-8 shown.

[0029] A method to improve the forming quality of laser melting deposition, it passes the heat accumulation factor X of the substrate R The monitoring of the forming quality parameters (such as contact angle, dilution rate, etc.) can be monitored indirectly, and the forming process parameters can be adjusted online accordingly, so that the matrix heat accumulation factor X R The value of is stable within the calibration range, thereby improving its process stability and processing quality. Specifically, the matrix heat accumulation factor X R = T R / R, the temperature T at the distance R after scanning the laser melting deposition molten pool is detected by non-contact temperature measuring equipment R , let X R = T R / R,X R That is, the heat accumulation factor based on the collection radius R, under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com