Novel sealing device of belt conveyor roller shaft under anti-corrosion and dust-proof special working conditions

A belt conveyor and sealing device technology, which is used in transportation and packaging, conveyor objects, rollers, etc., can solve problems such as affecting the safe operation of the belt conveyor, reducing the operating rate of the mining system, affecting the continuous coal output of the working face, etc. The effect of external leakage, avoiding sliding friction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

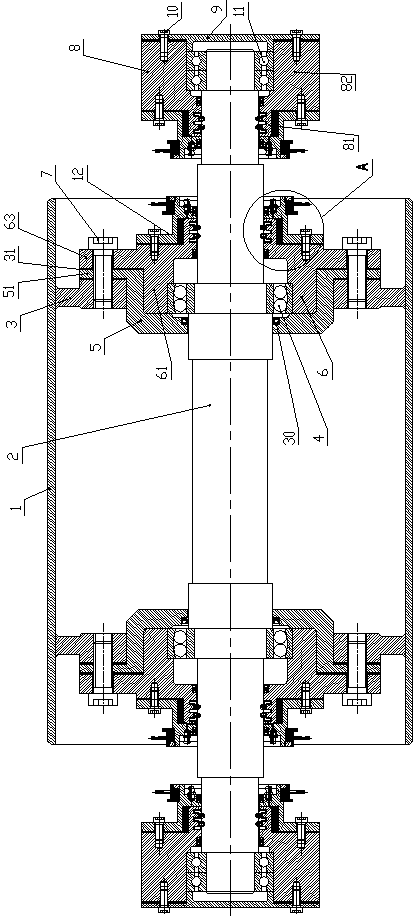

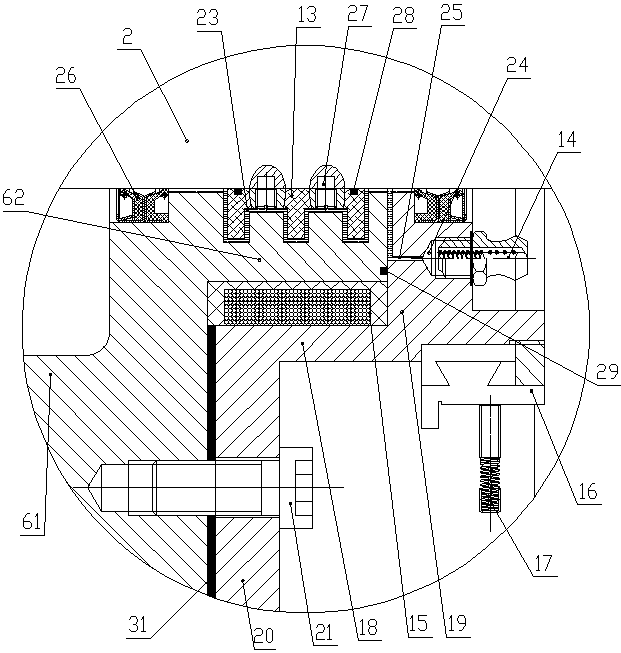

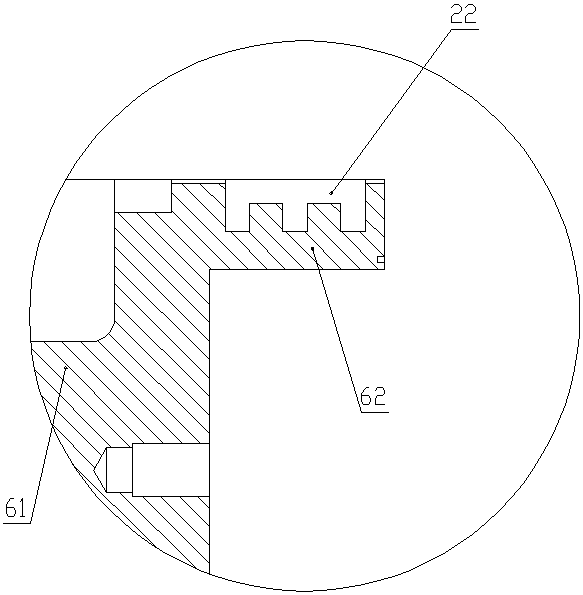

[0026] Such as Figure 1 to Figure 3 shown in figure 1 The left direction is the left direction of the present invention, that is, the figure 1 The orientation of the axis of the middle drum shaft is the left and right horizontal direction of the present invention, and the radial direction from the outer circle of the drum shaft to the inner circle of the drum is the direction from the inside to the outside. The new sealing device includes a drum 1 and a drum shaft 2. The left and right ends of the drum 1 are fixedly connected with a radial plate 3 inward along the circumferential direction. The radial plate 3 is welded on the drum 1, and the two radial plates 3 are respectively fixedly connected. There is a left first connecting seat and a right first connecting seat coaxial with the spoke plate 3, the structures of the left first connecting seat and the right first connecting seat are the same and symmetrical, and the drum shaft 2 is rotationally connected to the left by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com