Auxiliary heat treatment drying oven for cast iron robot joint

A technology of robots and joints, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems that are difficult to estimate, achieve the effects of reducing contact area, reducing the impact of slow low-temperature heat treatment, and stable and reliable safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

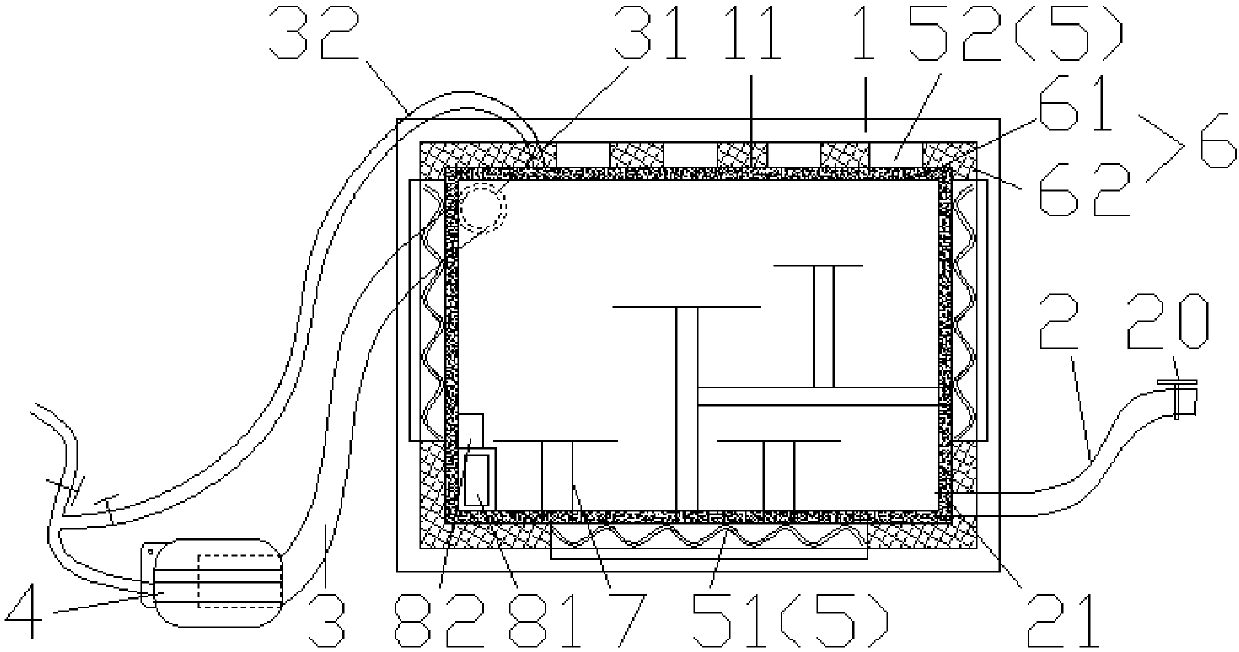

[0030] Such as figure 1 , an auxiliary heat treatment oven for cast iron robot joints, including a box body 1, an air intake pipe 2, a blast pipe 3, and a blower fan 4, and the inner layer of the box body 1 is provided with a heating device 5 and an insulating wall 6. The thermal insulation wall 6 is distributed around the heating device 5 and the inner wall surface 11 of the box body 1. The thermal insulation wall 6 is divided into a first thermal insulation wall 61 and a second thermal insulation wall 62 from close to the inner wall surface, and the heating device 5 includes an electric heating device. 51 and an infrared radiation device 52, the infrared rays radiated by the infrared radiation device 52 are far infrared rays, the thickness of the first thermal insulation wall 61 is 8-12mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com