High-efficiency circular blowing device for baking oven of tenter setting machine

A technology of tenter setting machine and oven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

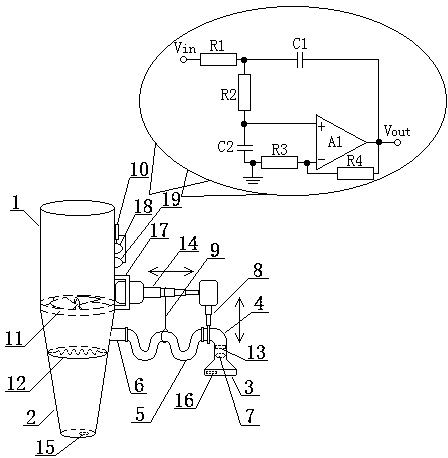

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] Such as figure 1As shown, the present invention designs a high-efficiency circulation blowing device in the oven of the stenter setting machine, which is used to be arranged on the top of the oven of the stenter setting machine, and is used for drying the weaving; it includes an air inlet duct 1 and an air outlet duct 2 , return air hood 3, return air duct 4, hose 5, drainage duct 6, desiccant 7, traction rope 9, main temperature sensor 15, secondary temperature sensor 16 and control module 10, and connected with control module 10 respectively The second electronically controlled telescopic rod 8, the main airflow driven fan 11, the heating resistance wire 12, the secondary airflow driven fan 13, the first electrically controlled telescopic rod 14, the main filter circuit 18, and the secondary filter circuit 19; t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap