Battery voltage detecting circuit

A battery voltage detection and circuit technology, applied in the electronic field, can solve the problems of inrush current, complicated circuit, and reduced reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

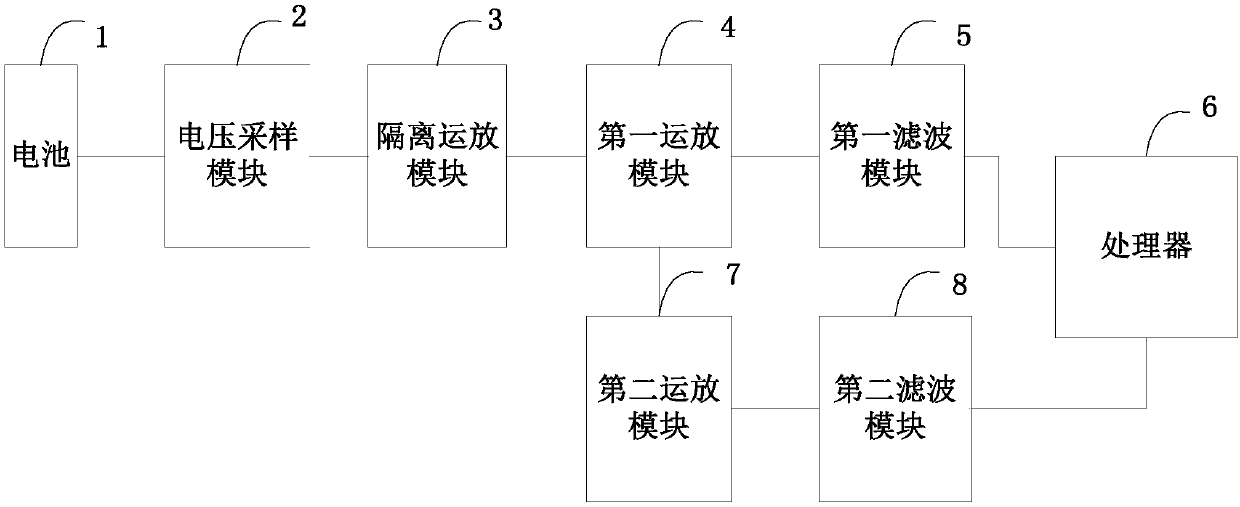

[0046] Please refer to figure 1 and figure 2 , Embodiment 1 of the present invention is:

[0047] A battery voltage detection circuit, comprising a voltage sampling module 2, an isolated operational amplifier module 3, a first operational amplifier module 4, a first filtering module 5 and a processor 6 connected in sequence, the voltage sampling module 2 is connected with the battery to be tested 1, and also includes a second op-amp module 7 and a second filter module 8 connected in sequence, the first op-amp module 4 is connected to the second op-amp module 7, and the second filter module 8 is connected to the processor 6 connected;

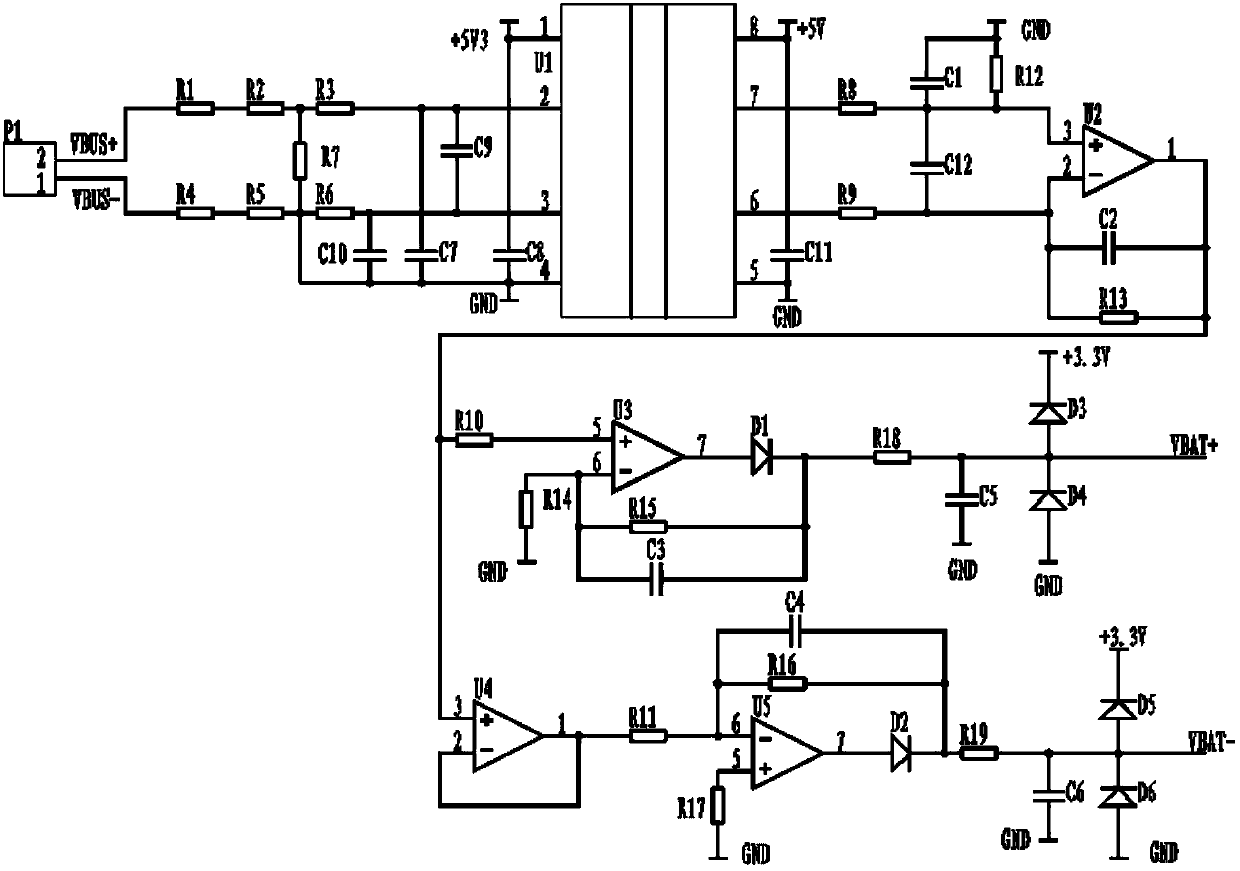

[0048] The first operational amplifier module 4 includes an eighth resistor, a ninth resistor, a tenth resistor, a fourteenth resistor, a first diode and a first operational amplifier chip. In an embodiment, the model of the first operational amplifier chip is OPA2348 , the first pin of the first operational amplifier chip is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com