Fin line type orthogonal-mode coupler based on double-ridge step structure

A technology of orthogonal mode coupler and steps, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problem that the in-band return loss characteristics of fin-line OMTs can not be fully considered relative to the working bandwidth, and achieve reduction Effects of device insertion loss, overall compactness, and wide bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

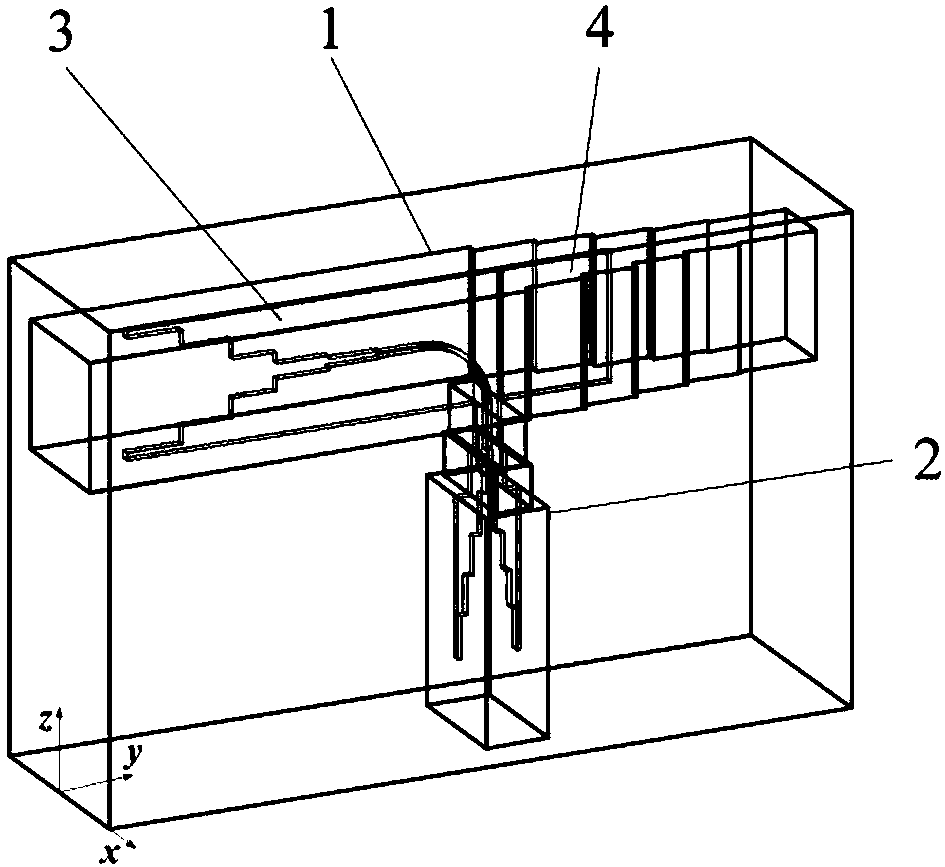

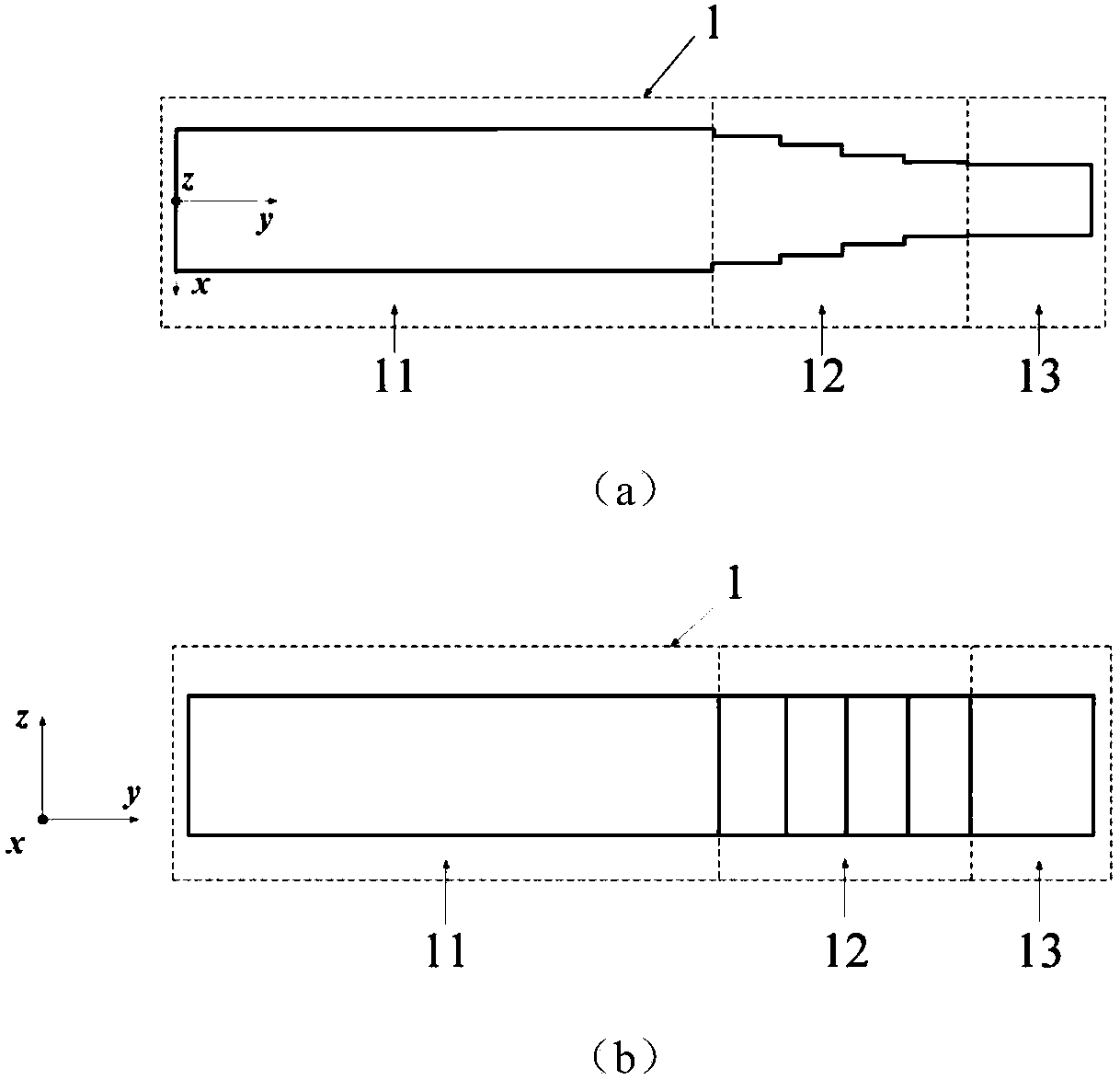

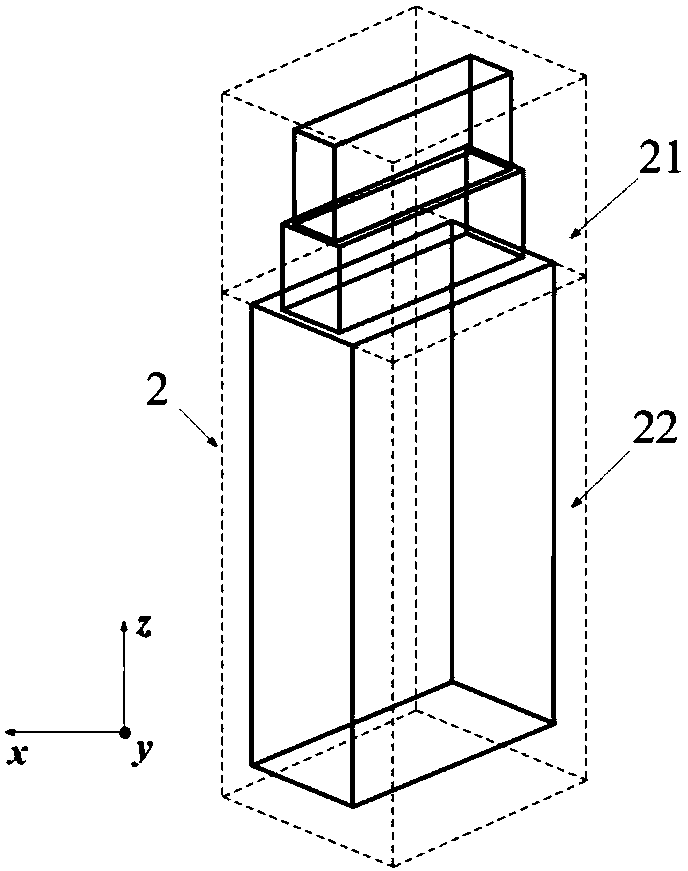

[0033] refer to figure 1 , a fin linear orthogonal mode coupler based on a double ridge step structure, including a waveguide body, the waveguide body adopts a three-port T-shaped waveguide structure composed of a horizontal waveguide 1 and a vertical waveguide 2 perpendicular to each other, wherein the horizontal waveguide 1 Sectional diagram of xoy plane figure 2 As shown in (a), the cross-sectional view of the xoz plane of the horizontal waveguide 1 is as follows figure 2 As shown in (b), the structural schematic diagram of the vertical waveguide 2 is as follows image 3 As shown, the T-shaped waveguide structure is symmetrical about the yoz plane, and a metal ridge 3 and an impedance absorbing piece 4 with a thickness of 0.4mm are installed next to the yoz symmetry plane of the waveguide structure, and the metal ridge 3 It consists of two parts, the horizontal metal ridge 31 and the vertical metal ridge 32, wherein the yoz section diagram of the horizontal metal ridge ...

Embodiment 2

[0040] Embodiment 2, the structure of this embodiment is the same as that of Embodiment 1, only for the resistance value R per square centimeter of the impedance absorbing sheet and the number of stepped gaps N on the horizontal metal ridge sheet 31 1 And each step parameter and the step-like gap series number N on the vertical metal ridge sheet 32 2 And the parameters of each step are adjusted:

[0041] Impedance absorbing sheet 4 adopts the ITO conductive glass material whose impedance value per square centimeter is R=50Ω; in the horizontal metal ridge sheet 31, the number of steps on the gap is 3, and each step is mirror-symmetrical about the longitudinal central axis of the metal patch, and the steps The length and spacing along the negative direction of the y-axis are 2.56mm×4.5mm, 2.26mm×2mm, 2.02mm×0.5mm respectively; in the vertical metal ridge 32, the number of steps on the gap is 2, and each step is about The longitudinal central axis of the sheet is mirror-symmetri...

Embodiment 3

[0042] Embodiment 3, the structure of this embodiment is the same as that of Embodiment 1, only for the resistance value R per square centimeter of the impedance absorbing sheet and the number of stepped gaps N on the horizontal metal ridge sheet 31 1 And each step parameter and the step-like gap series number N on the vertical metal ridge sheet 32 2 And the parameters of each step are adjusted:

[0043] Impedance absorbing sheet 4 adopts the ITO conductive glass material whose impedance value per square centimeter is R=500Ω; in the horizontal metal ridge sheet 31, the number of steps on the gap is 9, and each step is mirror-symmetrical about the longitudinal central axis of the metal patch, and the steps The length and spacing along the negative direction of the y-axis are 2.56mm×5mm, 2.26mm×4.2mm, 2.02mm×3.5mm, 2.02mm×2.75mm, 2.02mm×2.1mm, 2.02mm×1.5mm, 2.02mm× 1mm, 2.02mm×0.6mm, 2.02mm×0.25mm; in the vertical metal ridge 32, the number of steps on the gap is 8, each step i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com