Integrated forming method for storage tank base

A technology of integral forming and box bottom, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of poor weight reduction capacity, low forming efficiency, low structural rigidity, etc., achieve structural rigidity and reliability improvement, and shorten manufacturing Cycle time, effect of improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

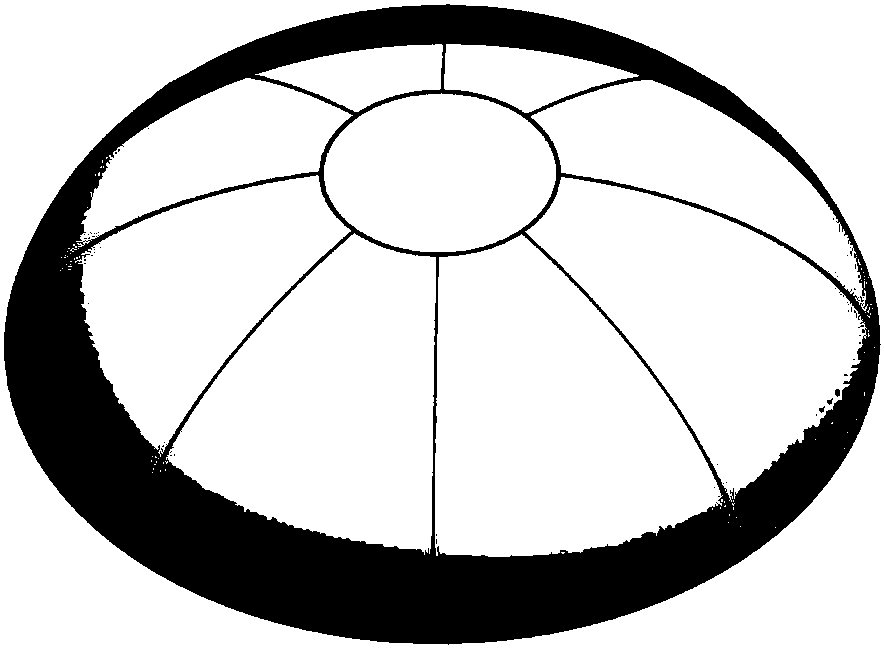

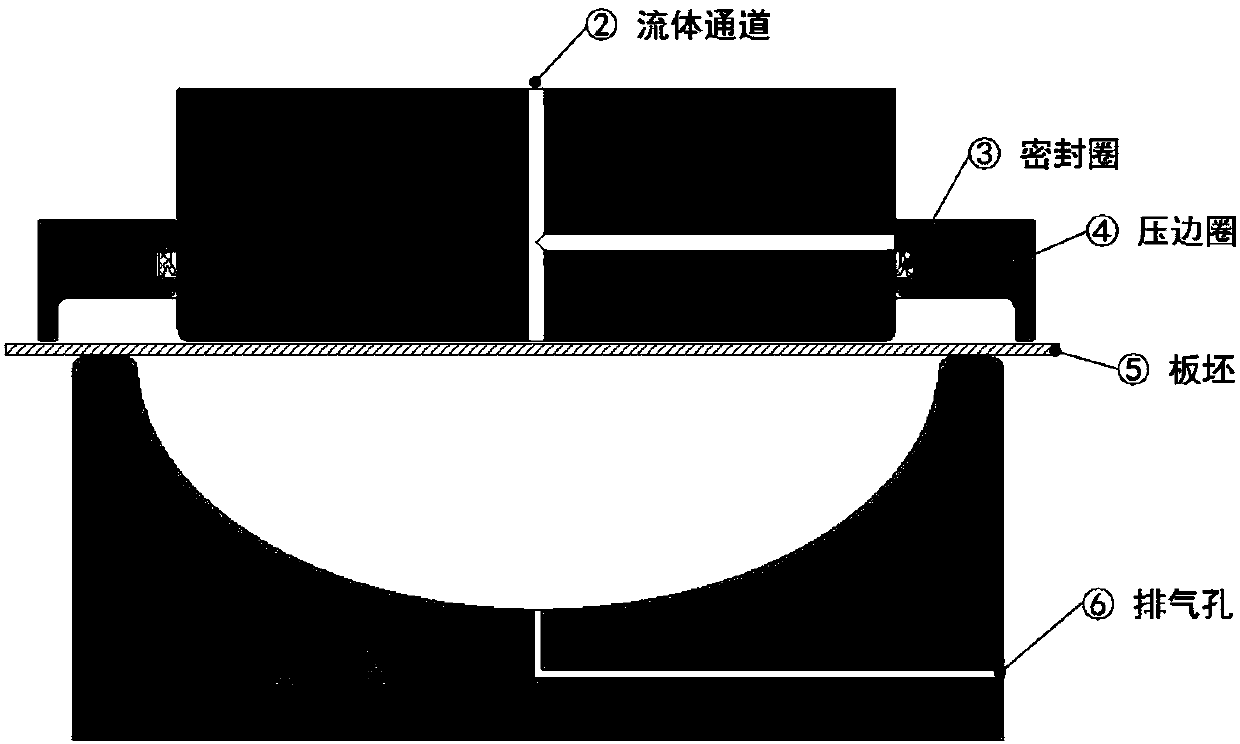

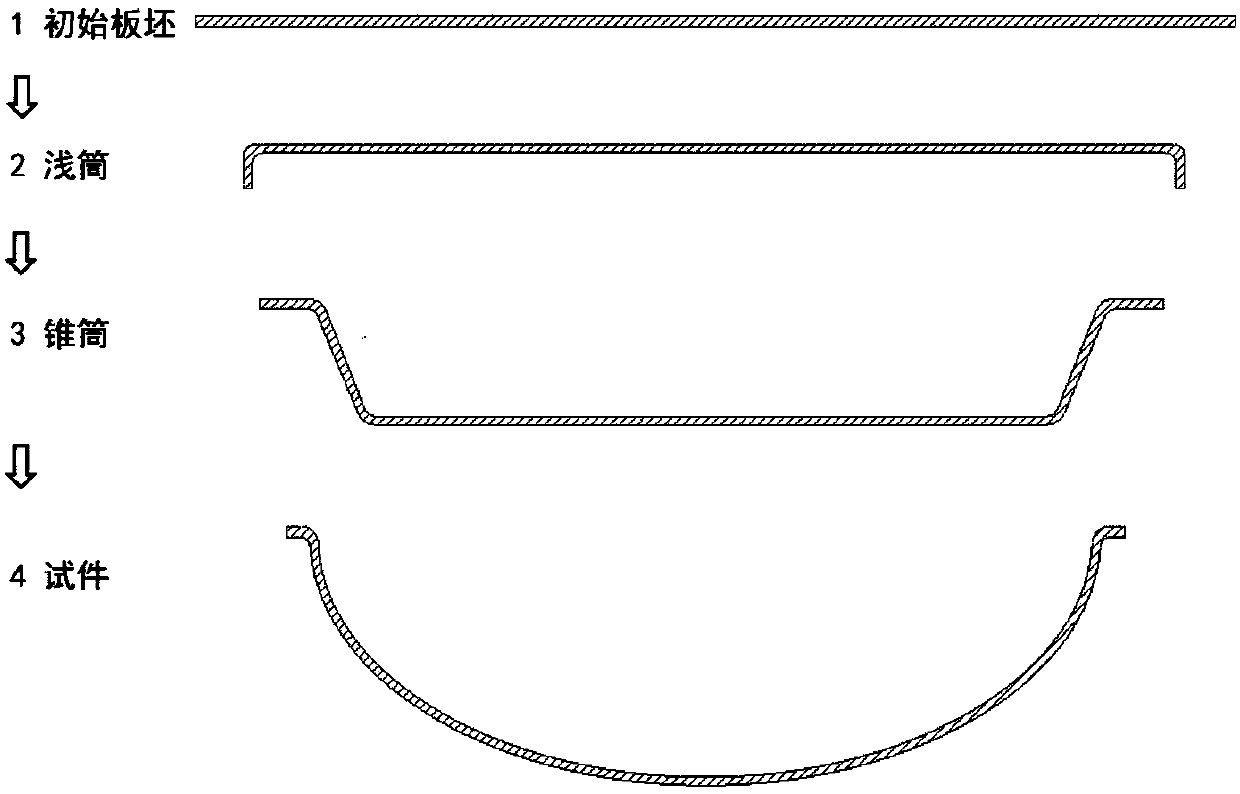

[0027] The integral forming method of the tank bottom proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0028] figure 2 Shown is a schematic diagram of the overall forming device for the bottom of the box. The device mainly includes a forming die (die, blank holder and punch), a sealing ring, a pressure medium channel and an exhaust hole. The forming die is based on the shape and size of the slab and the intermediate state. The sealing ring is used to seal the bulge forming fluid medium. The fluid channel is the channel through which the pressure medium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com