Short-process rolling method of high-strength plastic aln/az91d composite material

A composite material, short-process technology, applied in the field of high-strength plastic AlN/AZ91D composite short-process rolling, can solve the problems of poor room temperature deformability, high strength, low plasticity, etc., to suppress grain growth and pass pressure. The effect of large drop and short annealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

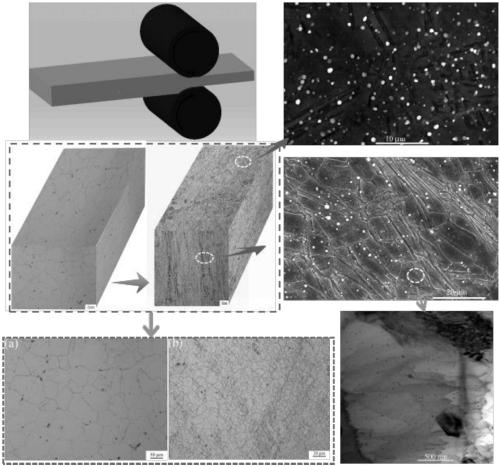

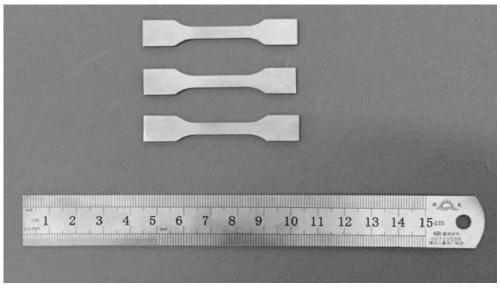

[0031] A rectangular plate with a size of 80×50×10 was cut from the AlN / AZ91 magnesium matrix composite material ingot as the original billet, and the preparation method of the composite material ingot is shown in Patent 201510882938.5;

[0032] Step 1: Put the AlN / AZ91 magnesium matrix composite material rectangular plate blank into the heat treatment furnace, solid solution at 400 ℃ ~ 425 ℃ for 20-30 hours, and then put it into water at 25 ℃ for water quenching;

[0033] Step 2: Remove the oxide scale on the surface of the sheet material after water quenching and prepare for cold rolling;

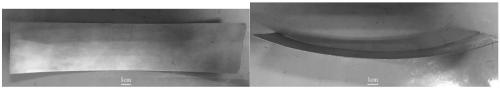

[0034]Step 3: During the cold rolling process, the rotation speed of the upper and lower rolls is 20-40r / min, and the cold rolling reduction of the first pass is 10% to 15%. Starting from the second pass, the cold rolling reduction of each pass The reduction amount is 15-25%, the cumulative rolling amount is 80%, the annealing temperature between passes is 300-350°C, and the annealing is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com