Semi-submersible type hydraulic testing device for vertical and axial suction centrifugal pump

A testing device and centrifugal pump technology, applied in the mechanical field, can solve problems such as large axial force and inability to directly measure NPSH, and achieve the effects of convenient installation and adjustment, improving versatility and application ability, and expanding the range of models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

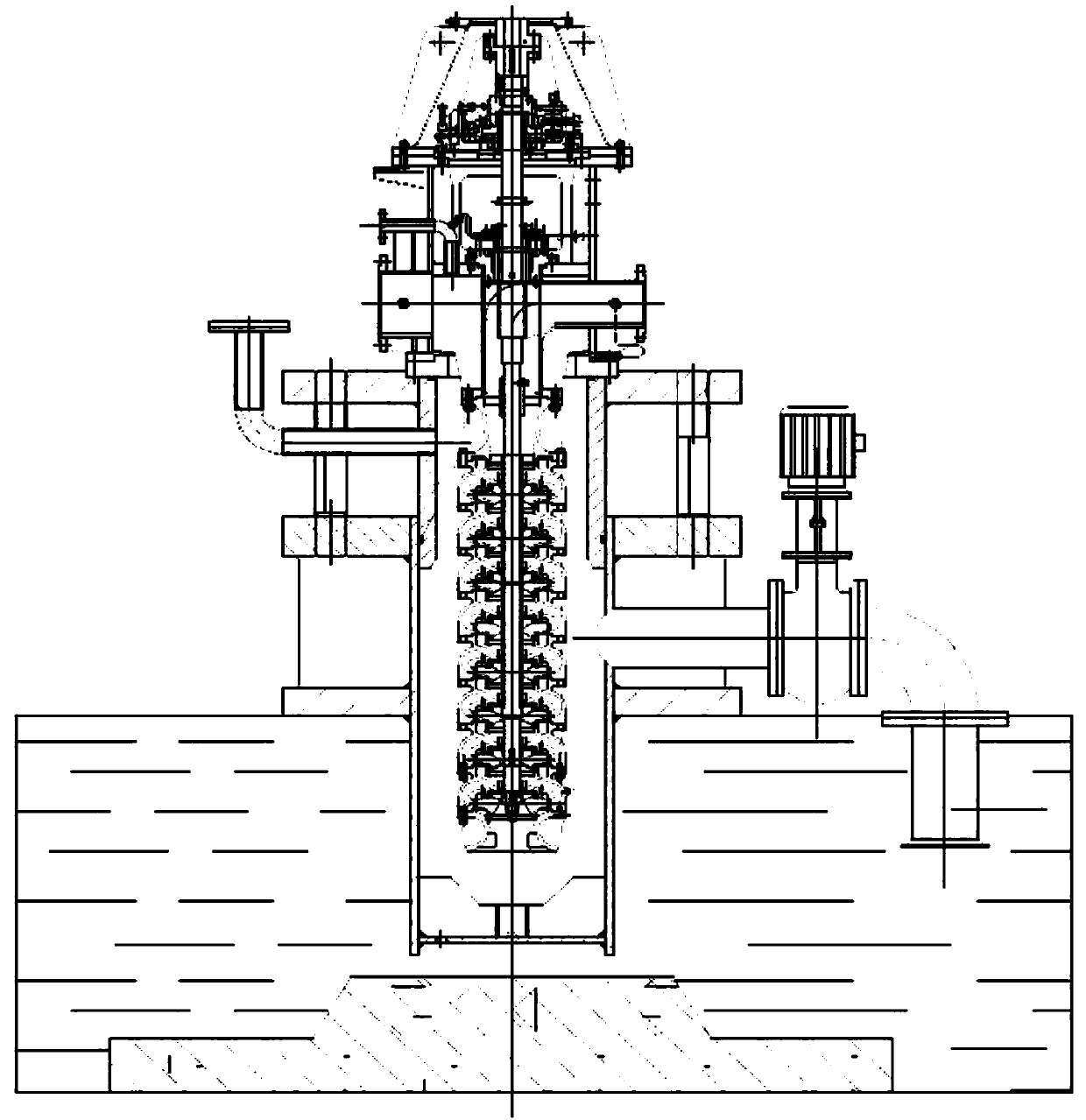

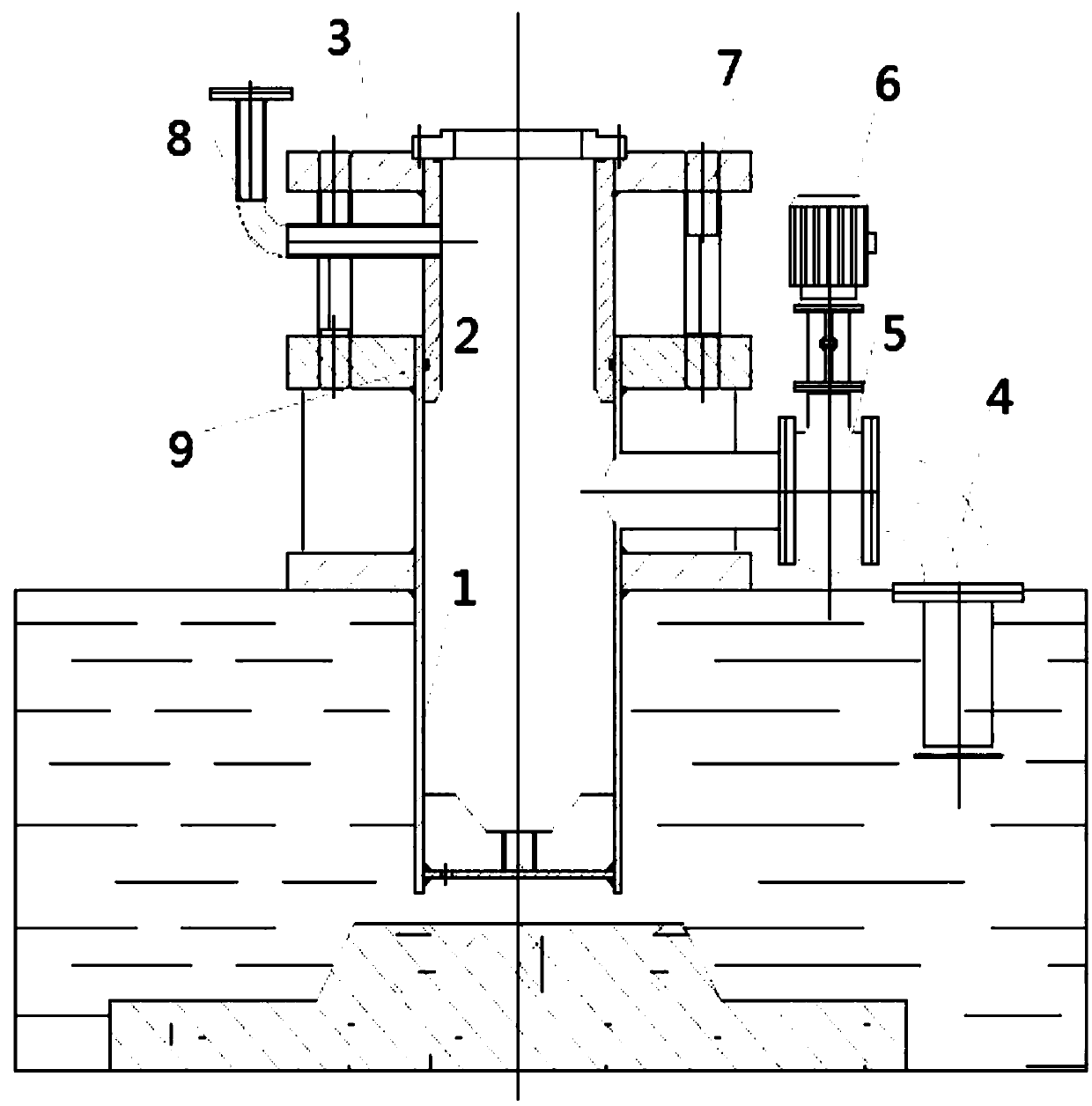

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0022] A vertical axial suction centrifugal pump semi-submersible hydraulic test device, such as figure 2 As shown, it includes test cylinder 1, lifting platform 2, water suction pipeline 4, executive motor 6, adjustment screw 7 and degassing pipe 8, water suction pipeline 4 is set on the right side of test cylinder 1, water suction pipeline 4 and The test cylinders 1 are connected to each other, and the test cylinder 1 is provided with a sealing filler 9 to make the test cylinder 1 in a better sealed state. The water suction pipeline 4 is also provided with a regulating valve 5 for NPSH test During the process, the vacuum degree in the test cylinder is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com