Cooling device for dairy products after hot filling

A cooling device and hot filling technology, used in dairy products, food preservation, milk preservation, etc., can solve the problems of poor material cooling effect and single air outlet direction, and achieve the effect of uniform and comprehensive cooling and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

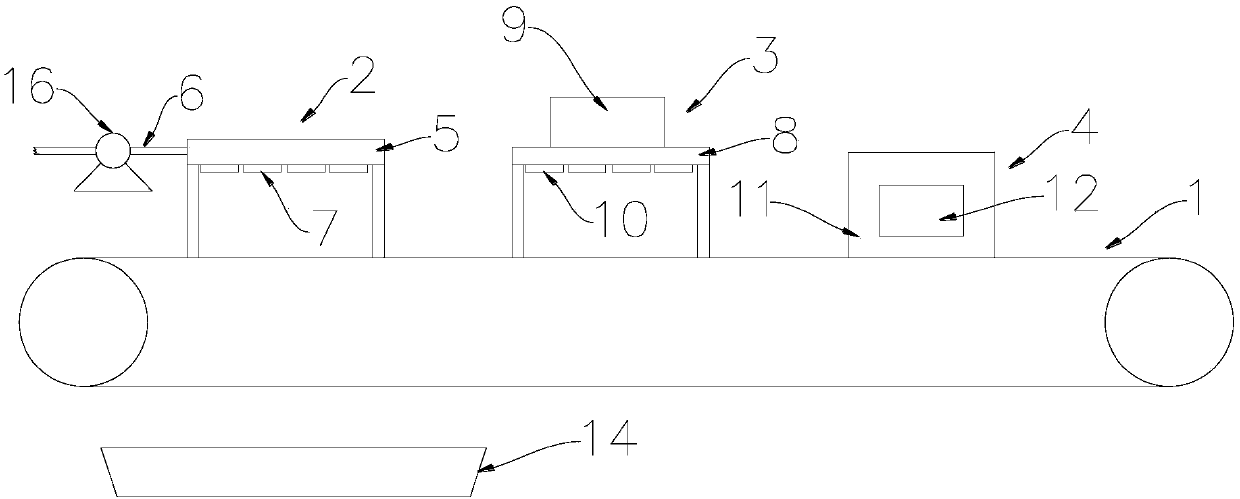

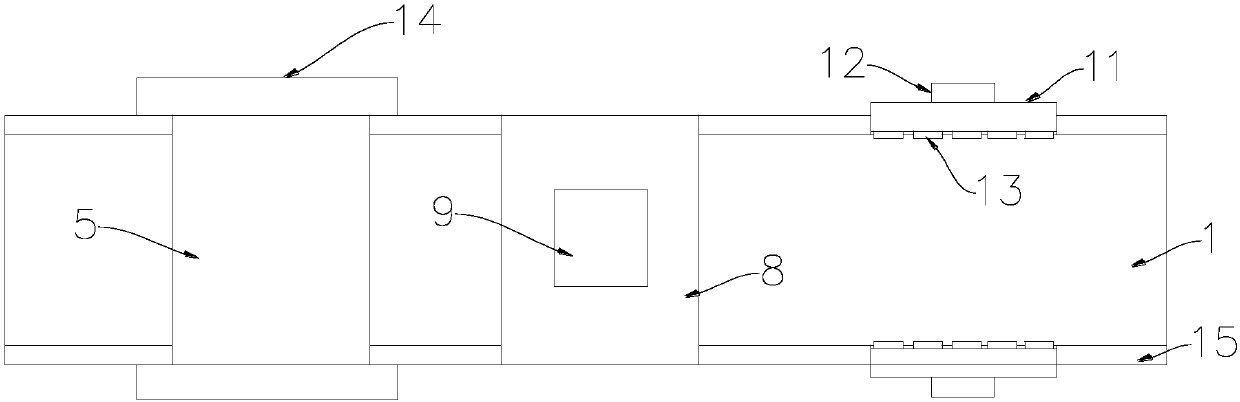

[0031] Such as figure 1 As shown, a cooling device for dairy products after hot filling, which includes a conveyor belt 1 and a water cooling mechanism 2, a first air cooling mechanism 3 and a second air cooling mechanism 4 arranged in sequence along the conveying direction of materials on the conveyor belt 1,

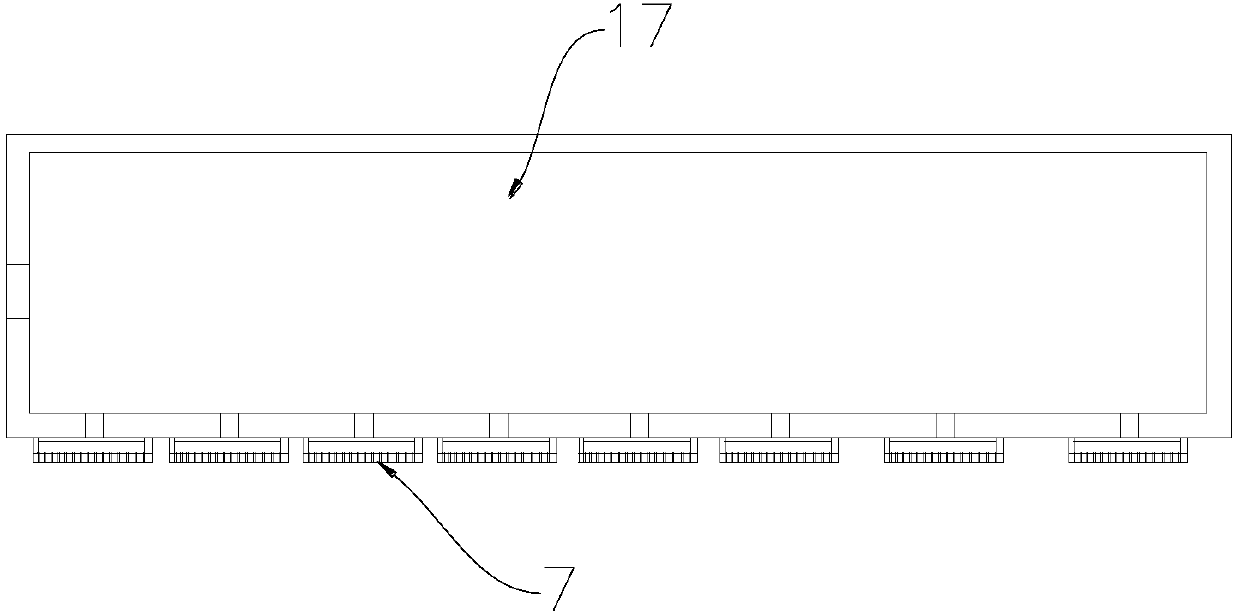

[0032] The water-cooling mechanism 2 includes a water-cooling cover plate 5 arranged above the conveyor belt 1, the water-cooling cover plate 5 has a water storage buffer chamber 17, and the water storage buffer chamber 17 communicates with the cold water pipeline 6, and the cold water pipeline 6 is provided with a booster pump 16, and the bottom of the water-cooled cover plate 5 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com