Automatic control coal gas experimental preparation device and experimental equipment

A coal mine gas and experimental technology, which is applied in transportation and packaging, mixer accessories, chemical instruments and methods, etc., can solve the problem of inability to accurately configure gas mixtures with different concentrations, and achieve the effect of saving manpower, low cost and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

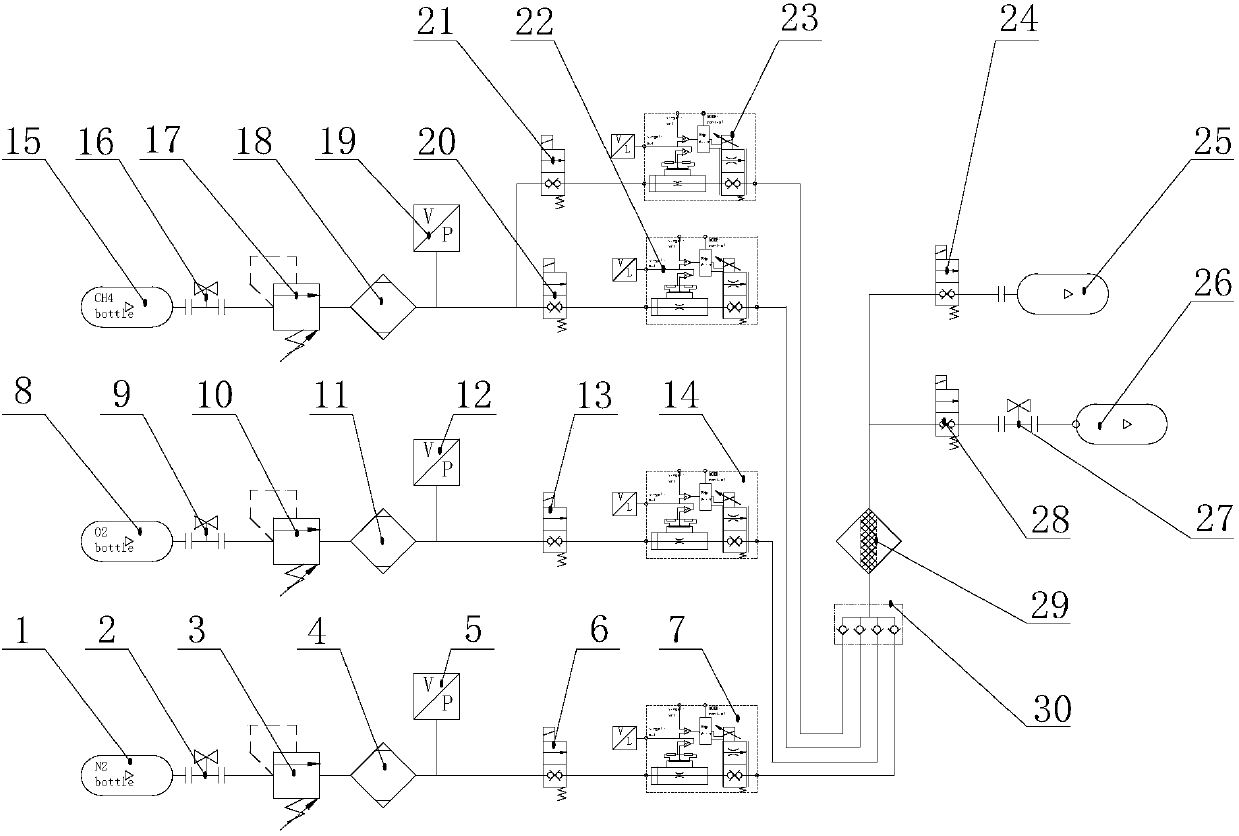

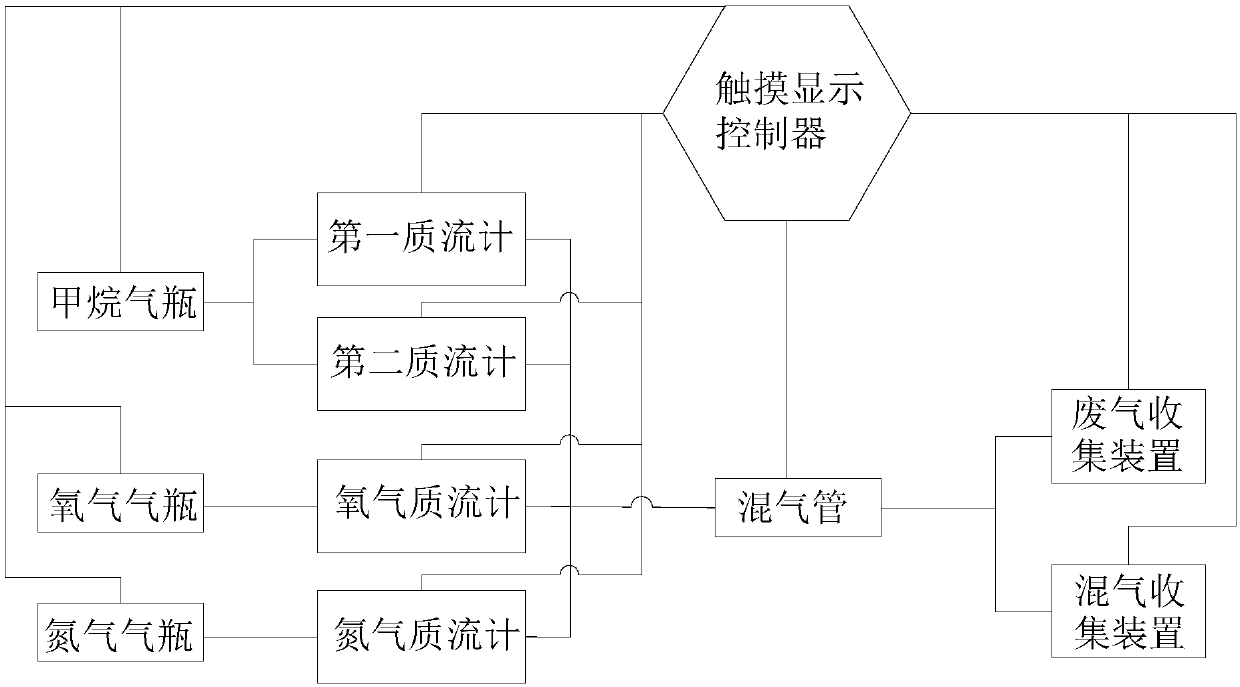

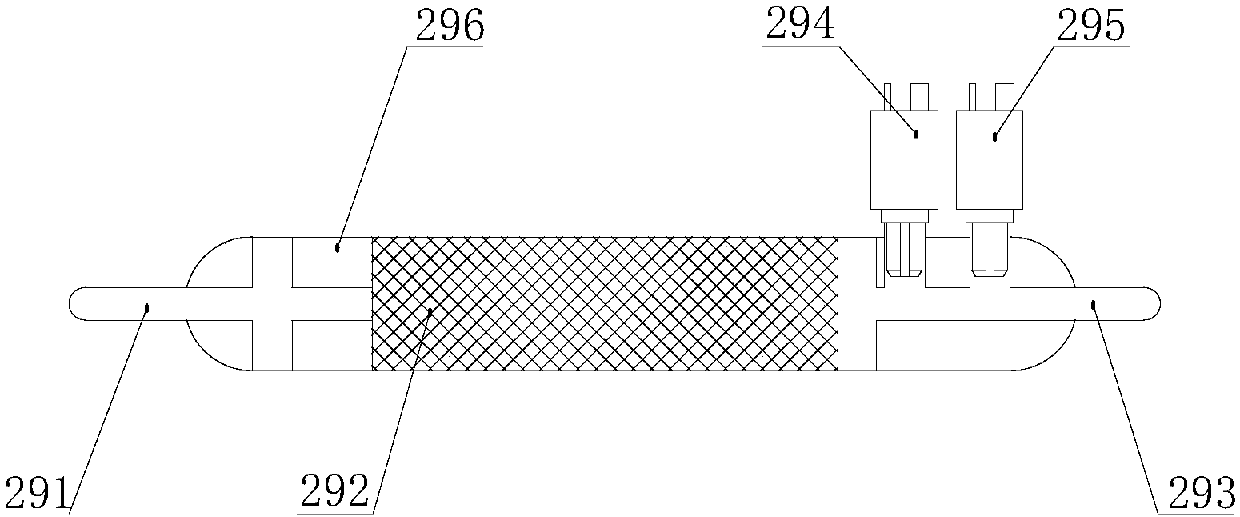

[0038] Such as Figure 1 to Figure 8 As shown, an automatic control coal mine gas experimental gas distribution device includes a nitrogen cylinder 1, which is equipped with a nitrogen on-off valve 2 and a nitrogen pressure reducing valve 3, and the nitrogen cylinder 1 is connected with a nitrogen drying tube 4 and a nitrogen drying tube 4 is connected with nitrogen pressure sensor 5 and nitrogen solenoid valve 6, nitrogen battery valve 6 is connected with nitrogen mass flow meter 7; oxygen cylinder 8 is equipped with oxygen on-off valve 9 and oxygen pressure reducing valve 10, oxygen cylinder 8 is connected with oxygen drying pipe 11, The oxygen drying pipe 11 is connected with an oxygen pressure sensor 12 and an oxygen solenoid valve 13, and the oxygen battery valve 13 is connected with an oxygen mass flow meter 14; the methane cylinder 15 is equipped with a methane switch valve 16 and a methane pressure reducing valve 17, and the methane cylinder 15 is connected with methane d...

Embodiment 2

[0074] The experimental equipment provided by the present invention includes the automatic control coal mine gas test gas distribution device as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com