Induction furnace, system for production of calcium carbide liquid with the same and method

A technology of induction furnace and quicklime powder, which is applied in the field of induction furnace to produce calcium carbide liquid and induction furnace, can solve the problems of restricting the popularization of hollow electrode technology, and achieve the effect of flexible production mode, short process flow and no noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0067] The present embodiment uses the system for producing calcium carbide liquid provided by the invention to produce calcium carbide liquid, and the specific method is as follows:

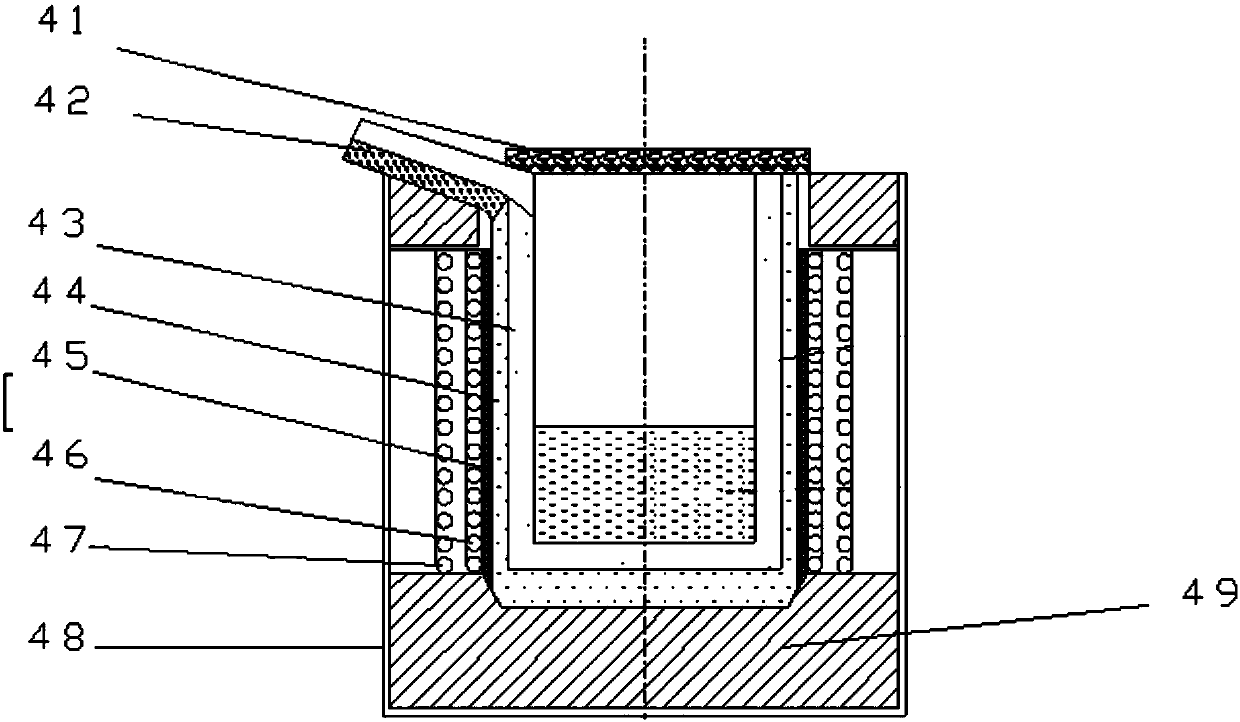

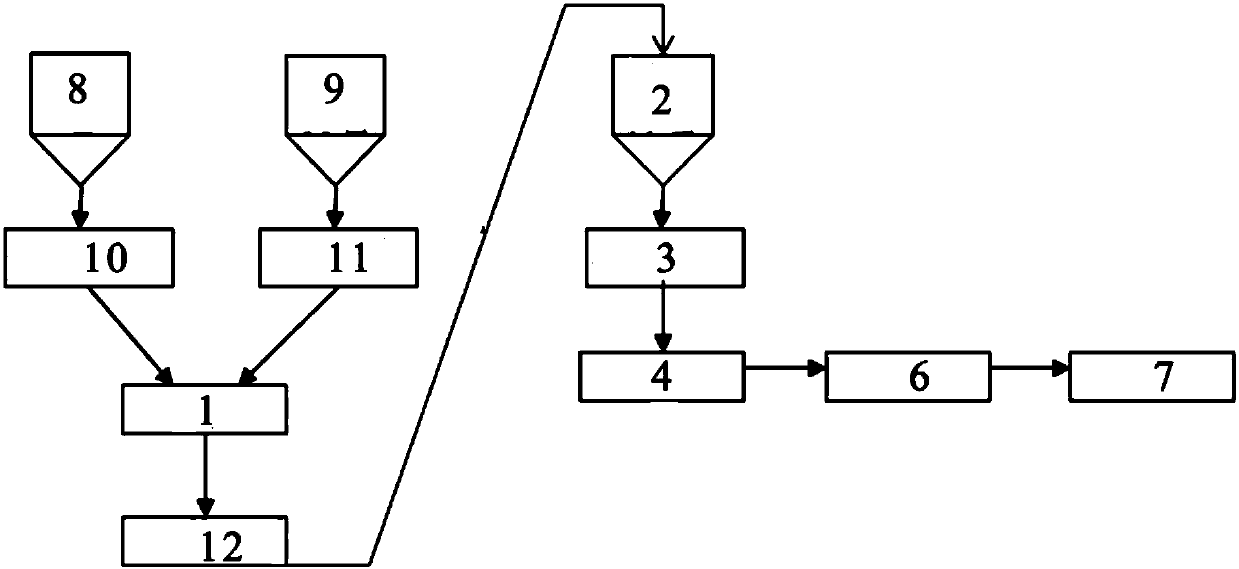

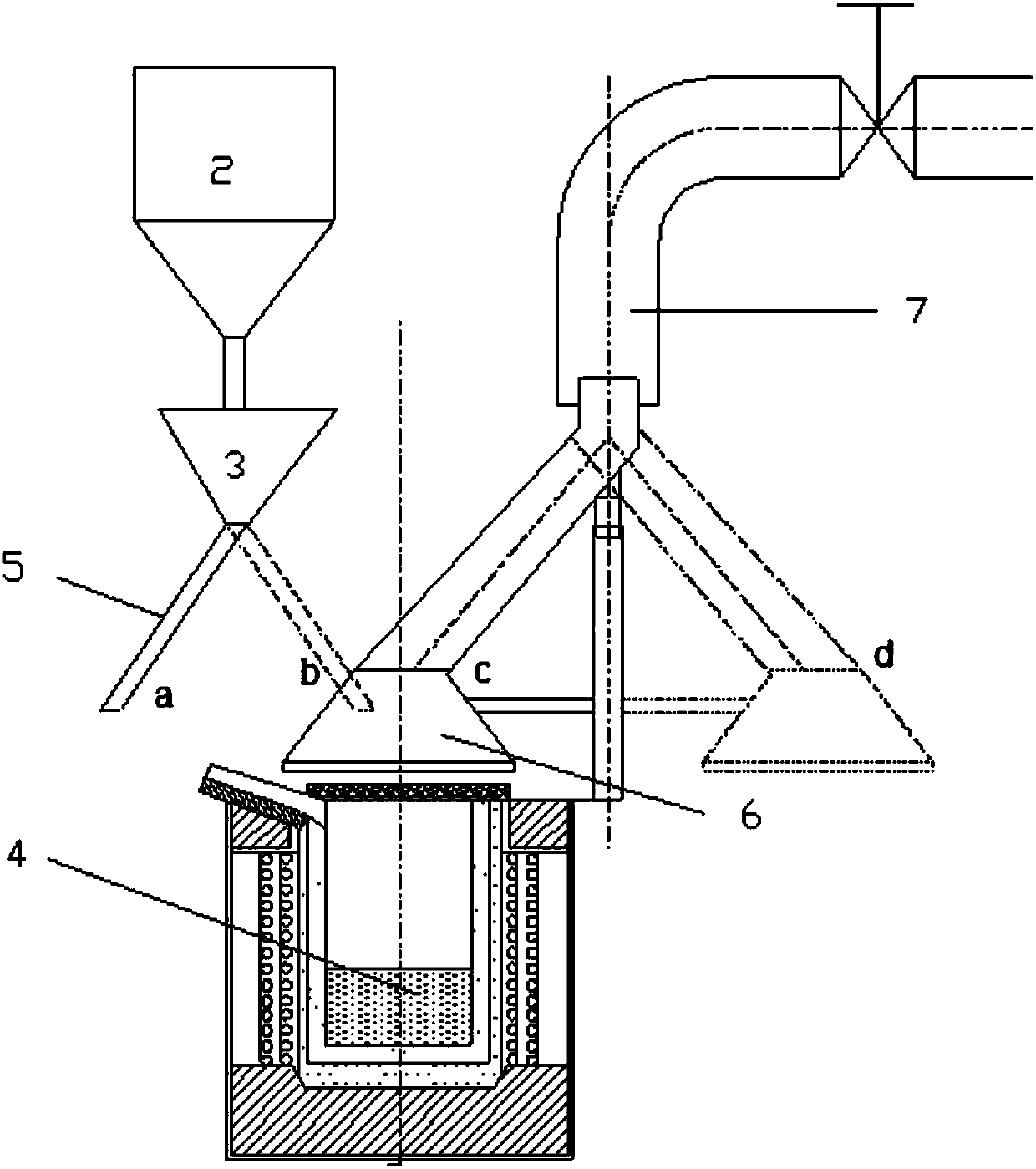

[0068] Put the carbon powder and quicklime powder from the toner bin and quicklime bin into the carbon powder weighing device and the quicklime powder weighing device for weighing, and put the weighed carbon powder 200Kg and quicklime powder 300Kg into the mixer respectively mix in. After mixing evenly, put it into the hopper below it, then lift the hopper filled with the mixture to the top of the mixing silo through the hopper elevator, add the mixture into the mixing silo, and put the mixture into the mixing weighing device middle. Put the feeding pipe from the waiting position of the feeding pipe to the feeding position of the feeding pipe, and add 200Kg of the weighed mixture into the induction furnace. After adding the material, cover the furnace cover, and put the dust removal hood from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com