Method for preparing sodium columbate nanowire by cation exchange approach

A cation exchange and nanowire technology, which is applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of difficult synthesis of sodium niobate nanowires, and achieve low cost, good repeatability, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) First use SnNb 2 o 6 The nanosheets are dispersed in deionized water, and sodium hydroxide is added to make a paste, and then ethylenediamine is added.

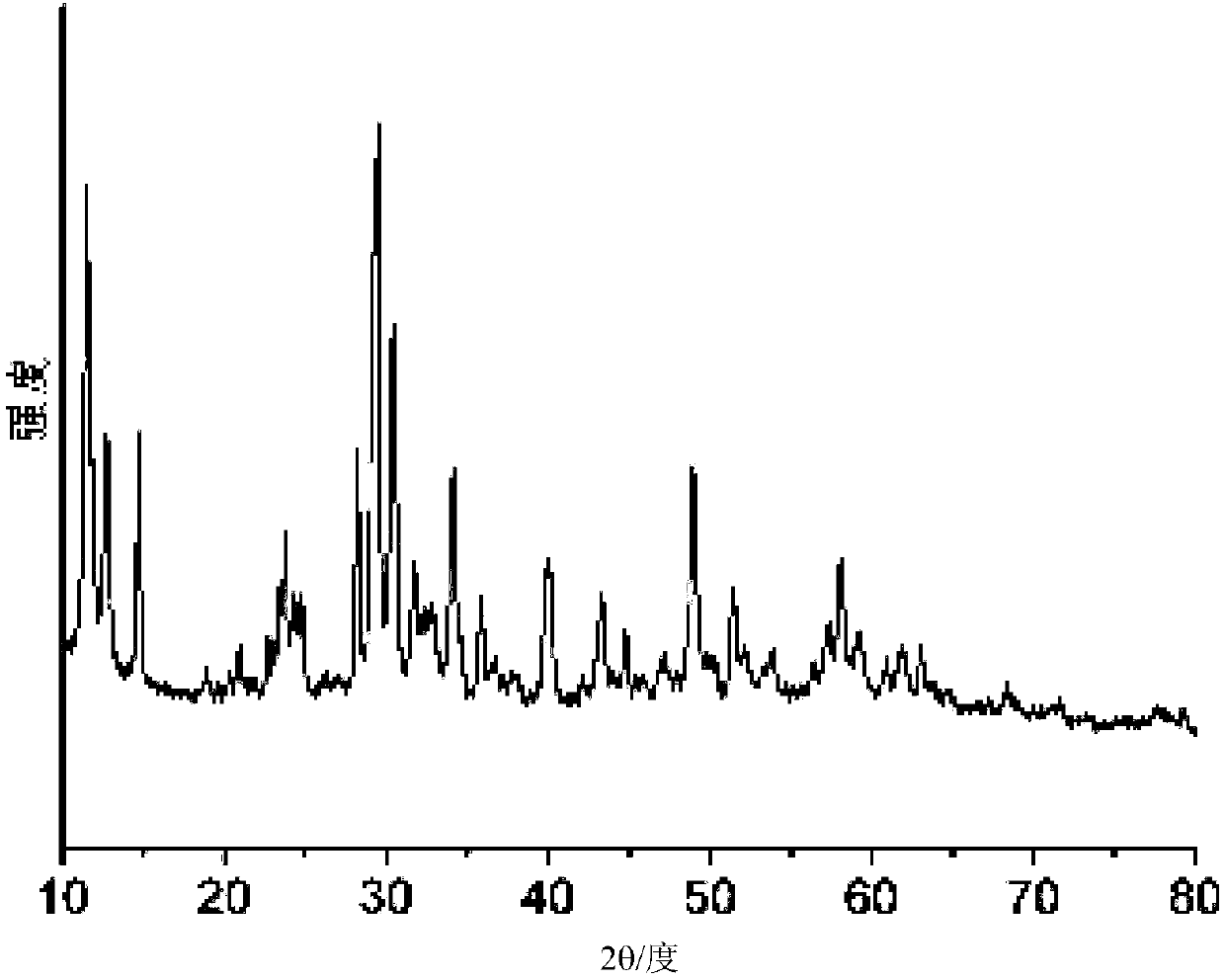

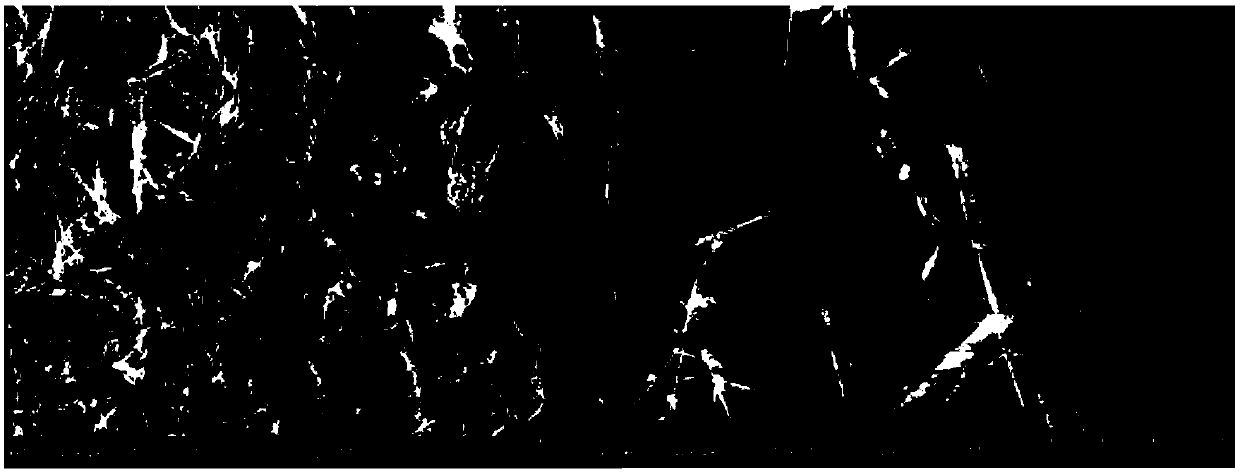

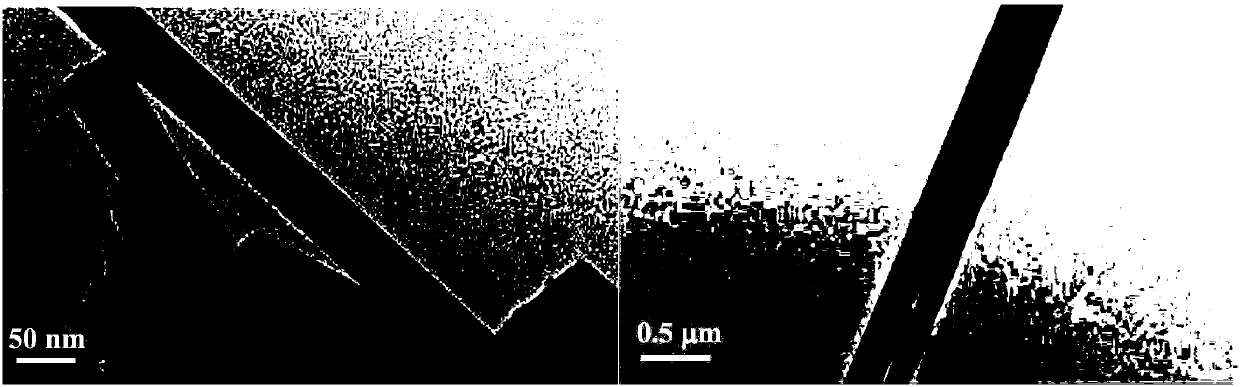

[0022] (2) Using the solution obtained in step (1) as a reaction precursor, heat treatment in a closed reactor (volume 20ml) at a temperature of 180°C and a treatment time of 24 hours successfully prepared Na 6 Nb 8 o 25 9H 2 O nanowires;

[0023] where SnNb 2 o 6 The dosages of nanosheets and NaOH are 0.2g and 0.6g respectively, the dosages of deionized water and ethylenediamine are 9.5mL and 0.5mL respectively, and the final aspect ratio of nanowires is 200:1

Embodiment 2

[0025] (1) First use SnNb 2 o 6 The nanosheets are dispersed in deionized water, and sodium hydroxide is added to make a paste, and then ethylenediamine is added.

[0026] (2) Using the solution obtained in step (1) as a reaction precursor, it was heat-treated in a closed reactor (volume 20ml) at a temperature of 200°C for 12 hours, and Na 6 Nb 8 o 25 9H 2 O nanowires;

[0027] where SnNb 2 o 6 The dosages of nanosheets and NaOH were 0.1g and 0.4g, respectively; the dosages of deionized water and ethylenediamine were 8mL and 2mL, respectively. The aspect ratio of the final nanowire is 5:1

Embodiment 3

[0029] (1) First use SnNb 2 o 6 The nanosheets are dispersed in deionized water, and sodium hydroxide is added to make a paste, and then ethylenediamine is added.

[0030] (2) Using the solution obtained in step (1) as the reaction precursor, it was heat-treated in a closed reactor (volume 20ml) at a temperature of 190°C for 18 hours, and Na 6 Nb 8 o 25 9H 2 O nanowires;

[0031] where SnNb 2 o 6 The dosages of nanosheets and NaOH were 0.2g and 0.4g, respectively; the dosages of deionized water and ethylenediamine were 9mL and 1mL, respectively. The aspect ratio of the final nanowire is 80:1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com