Titanium dioxide sedimentation device

A settling device, titanium dioxide technology, applied in the direction of sedimentation treatment, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. , Improve the recycling rate and reduce the effect of water disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

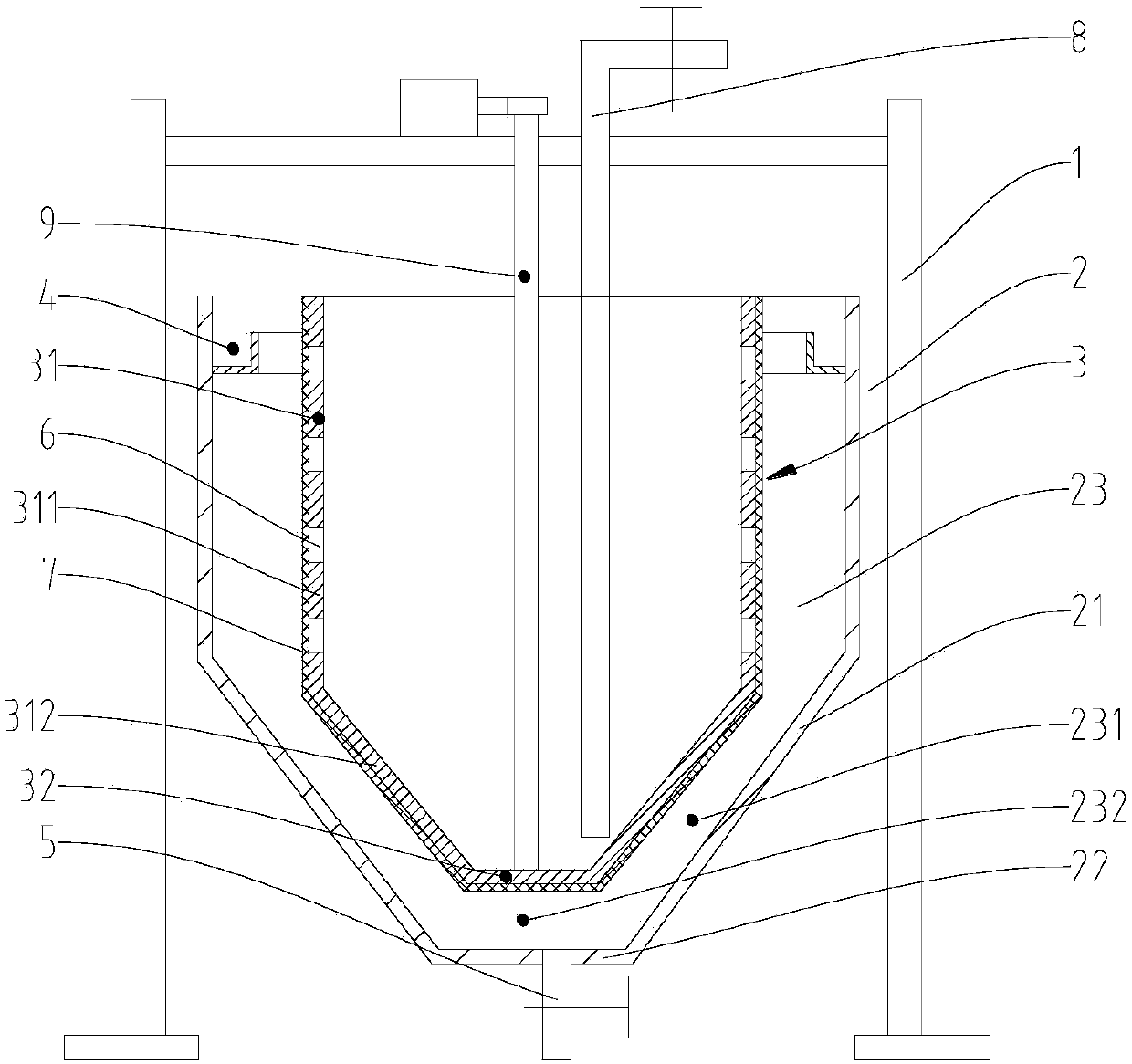

[0014] Titanium dioxide settling device, such as figure 1 As shown, it includes a support 1, a tank body 2 and a drainage cylinder 3; the tank body 2 includes a tank wall 21 and a tank bottom 22; a settling tank 23 with an open upper end surrounded by the tank wall 21 and the tank bottom 22; The tank body 2 is supported on the bracket 1, the drainage tube 3 is supported on the bracket 1 and is located in the settlement tank 23, the drainage tube 3 includes a tube wall 31 and a tube bottom 32; between the tank body 2 and the tube wall 31 of the drain tube 3 A flocculation zone 231 is formed between them; a sedimentation zone 232 located below the flocculation zone 231 is formed between the bottom 32 of the drainage tube 3 and the tank bottom 22;

[0015] A ring overflow tank 4 is provided on the inner wall of the tank body 2; a sediment outlet 5 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com