Agilawood essential oil vacuum fractionation method

The technology of agarwood essential oil and vacuum fractionation, which is applied in the field of essential oil fractionation, can solve the problems of poor quality, low fractionation efficiency and high cost of agarwood essential oil fractionation, and achieves the effects of convenient control, guaranteed collection purity, and accelerated rapid distillation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

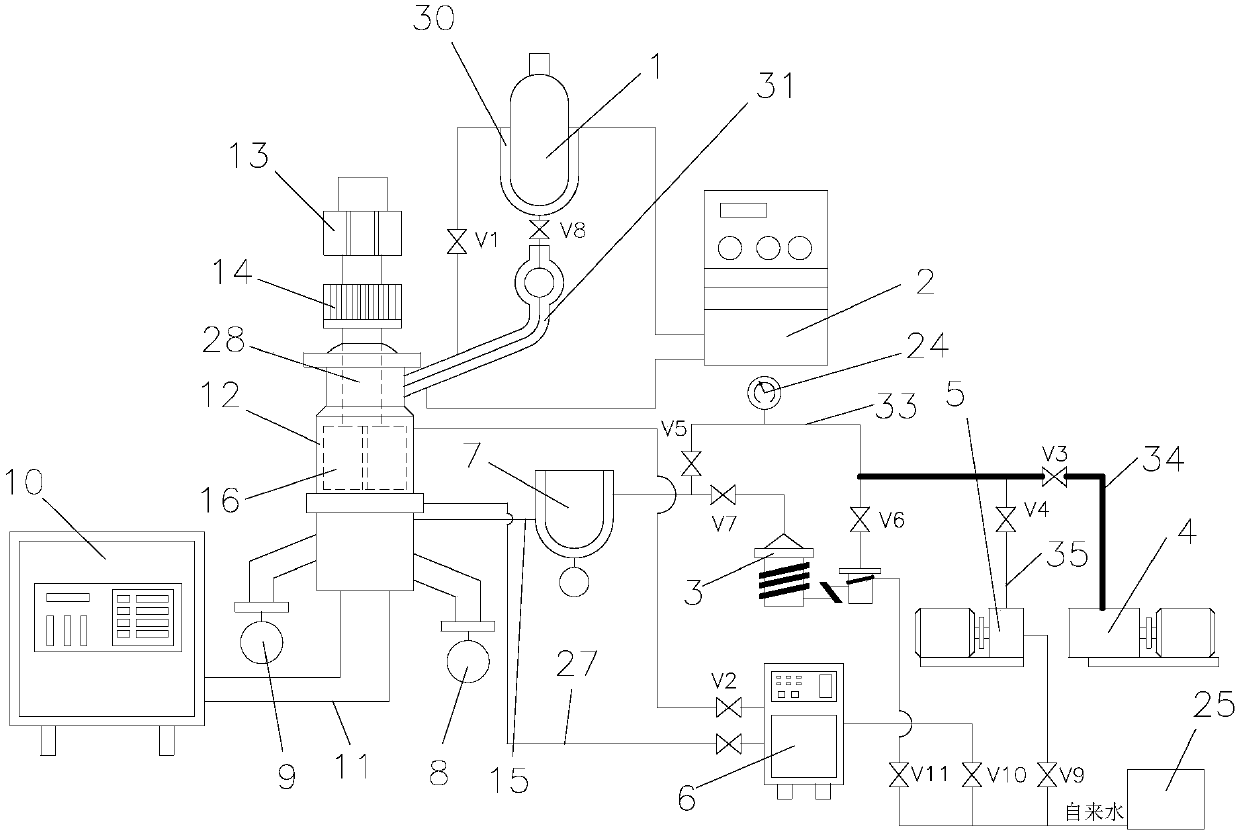

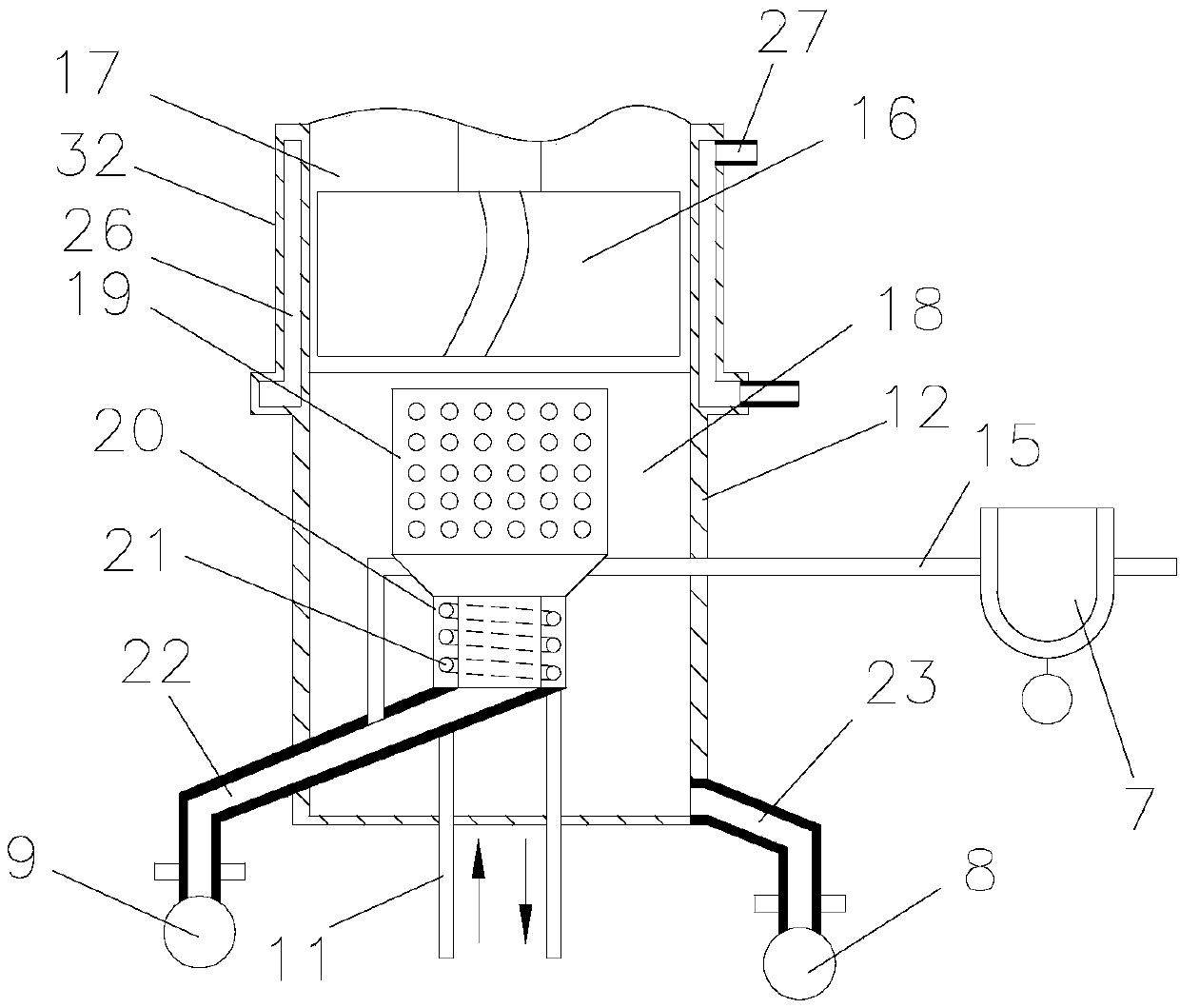

[0090] A kind of agarwood essential oil vacuum fractionation method, adopts Figure 1-4 device to run, including the following steps:

[0091] (1) Preliminary preparation:

[0092] crushing agarwood wood into agarwood powder with a particle size of 40-60 meshes, and then extracting the agarwood by a supercritical fluid extraction method to obtain an agarwood essential oil extract;

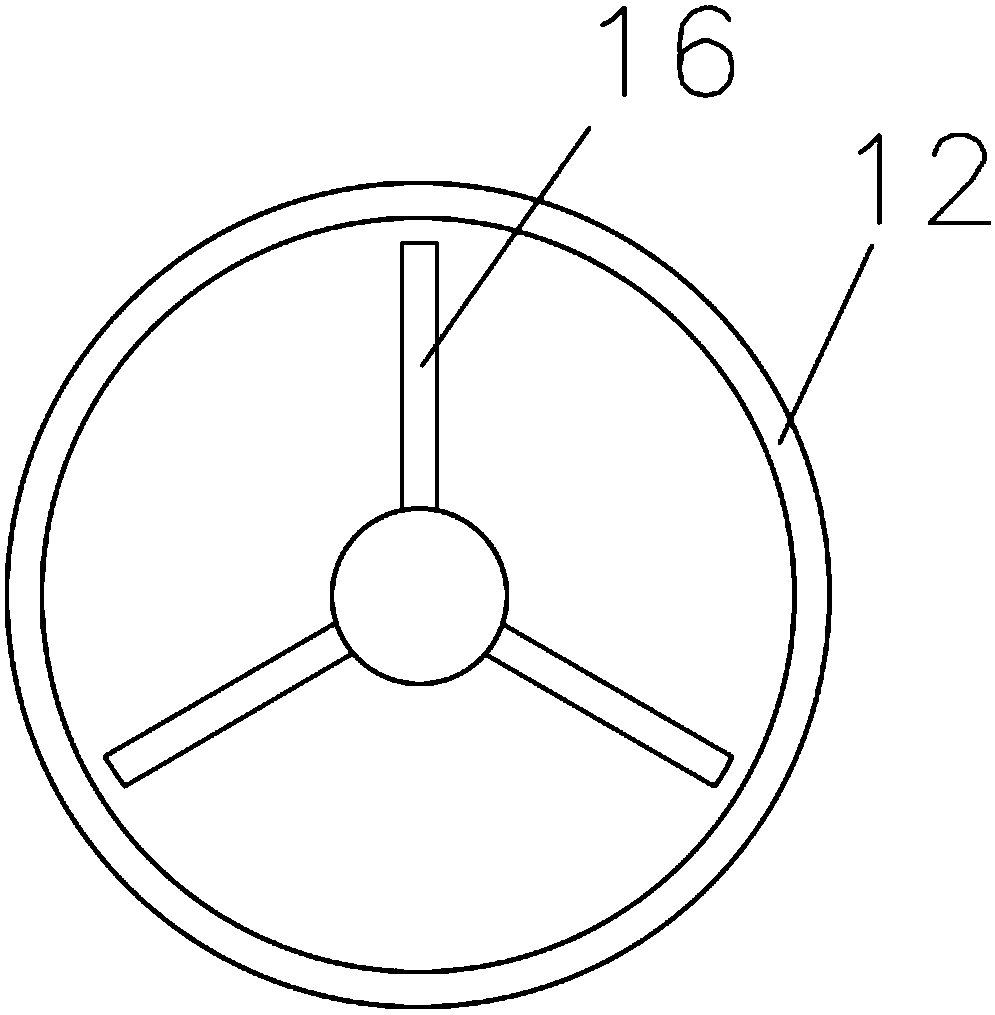

[0093] Place the agarwood essential oil extract in the raw material tank 1 and preheat it to 70°C; preheat the distiller 12 to 130°C, preheat the scraping film 16 to 130°C, and precool the condenser tube 20 to 26°C; then The vacuum degree in the distiller 12 reaches 3.0Pa by the vacuum pump 4; The vacuum degree in the distiller 12 reaches 1.0Pa by the diffusion pump 3;

[0094] (2) Fractionation process:

[0095] The preheated agarwood essential oil extract flows out from the raw material tank 1, and is added into the still 1 along the tube wall of the still 2 at a speed of 80mL / s; The membrane...

Embodiment 2

[0110] A kind of agarwood essential oil vacuum fractionation method, adopts Figure 1-4 device to run, including the following steps:

[0111] (1) Preliminary preparation:

[0112] Crushing the agarwood wood into agarwood powder with a particle size of 60 meshes, and then extracting it with a supercritical fluid extraction method to obtain an agarwood essential oil extract; placing the agarwood essential oil extract in the raw material tank 1, and preheating to 60°C;

[0113] The distiller 12 is preheated to 122°C, the wiper film 16 is preheated to 122°C, and the condenser tube 20 is precooled to 30°C; The vacuum degree in distiller 12 reaches 1.2Pa;

[0114] (2) Fractionation process:

[0115] The preheated agarwood essential oil extract flows out from the raw material tank 1, and is added into the still 1 along the tube wall of the still 2 at a speed of 90mL / s; the scraper control device 14 drives the scraper at a speed of 400r / min The diaphragm 16 rotates, and the scrap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com