Cleaning agent used for cleaning after glass UV drawing

A post-cleaning and cleaning agent technology, applied in the directions of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problem that UV glue cannot pass the boiling test, glue removal, UV glue separation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

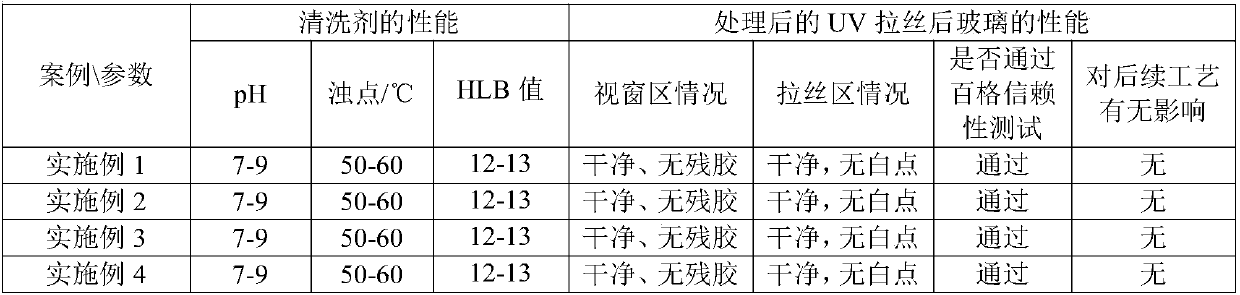

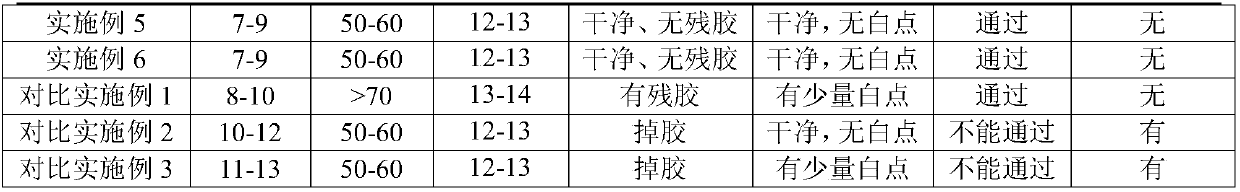

Embodiment 1

[0047] A cleaning agent for cleaning glass after UV wire drawing, comprising the following components in parts by weight: 6 parts of inorganic auxiliary agent, 2 parts of chelating agent, 2 parts of dispersant, 15 parts of surfactant, 2 parts of cosolvent, 1 part of glycerin and 72 parts of water.

[0048] The inorganic auxiliary agent is composed of 1 part of sodium tripolyphosphate and 5 parts of sodium gluconate.

[0049] The chelating agent is disodium edetate.

[0050] The dispersant is sodium tripolyphosphate.

[0051] The surfactant is composed of 10 parts of alkylphenol polyoxyethylene ether and 5 parts of fatty alcohol polyoxyethylene ether.

[0052] The co-solvent is an alkyl glycoside.

[0053] The above-mentioned preparation method of the cleaning agent used for cleaning glass after UV wire drawing is specifically:

[0054] The first step is to introduce water into the cleaned stirring tank;

[0055] Second step, import inorganic auxiliary agent (herein sodium...

Embodiment 2

[0060]A cleaning agent for cleaning glass after UV wire drawing, comprising the following components in parts by weight: 3 parts of inorganic auxiliary agent, 2 parts of chelating agent, 2 parts of dispersant, 13 parts of surfactant, 3 parts of cosolvent, 1 part of glycerin and 76 parts of water.

[0061] The inorganic auxiliary agent consists of 2 parts of sodium tripolyphosphate and 1 part of potassium pyrophosphate.

[0062] The chelating agent is disodium edetate.

[0063] The dispersant is sodium tripolyphosphate.

[0064] The surfactant is composed of 8 parts of fatty alcohol polyoxyethylene ether and 5 parts of isomeric alcohol polyoxyethylene ether.

[0065] The cosolvent is H-66 cosolvent.

[0066] The preparation method of the cleaning agent for cleaning glass after UV drawing is the same as that in Example 1.

[0067] The performance parameters of the cleaning agent obtained in this embodiment are shown in Table 2.

Embodiment 3

[0069] A cleaning agent for cleaning glass after UV wire drawing, comprising the following components in parts by weight: 5 parts of inorganic auxiliary agent, 2 parts of chelating agent, 2 parts of dispersant, 13 parts of surfactant, 2 parts of cosolvent, 1 part glycerin and 75 parts water.

[0070] The inorganic auxiliary agent consists of 3 parts of sodium glucoheptonate and 2 parts of sodium citrate.

[0071] The chelating agent is disodium edetate.

[0072] The dispersant is dispersant 445N.

[0073] The surfactant is composed of 8 parts of fatty alcohol polyoxyethylene ether and 5 parts of isomeric alcohol polyoxyethylene ether.

[0074] The co-solvent is an alkyl glycoside.

[0075] The preparation method of the cleaning agent for cleaning glass after UV drawing is the same as that in Example 1.

[0076] The performance parameters of the cleaning agent obtained in this embodiment are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com