A kind of superalloy casting and preparation method thereof

A high-temperature alloy and casting technology, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of destroying the stability of the high-temperature long-term aging structure of the alloy, deteriorating the creep and durability of the alloy, and achieving excellent high-temperature resistance. The effects of corrosion performance, good structural stability, and good high-temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

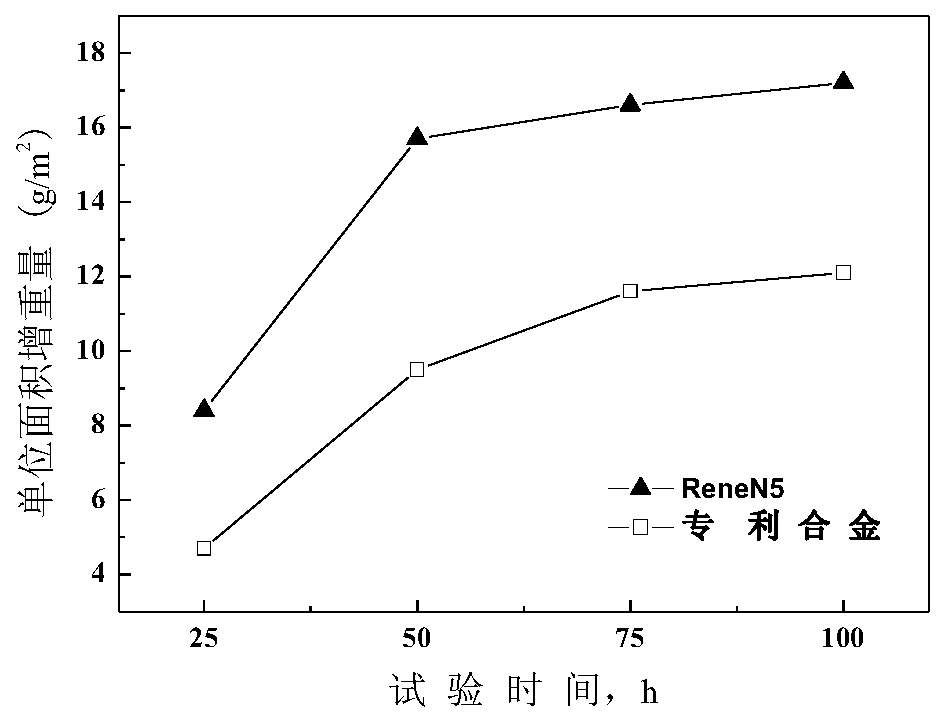

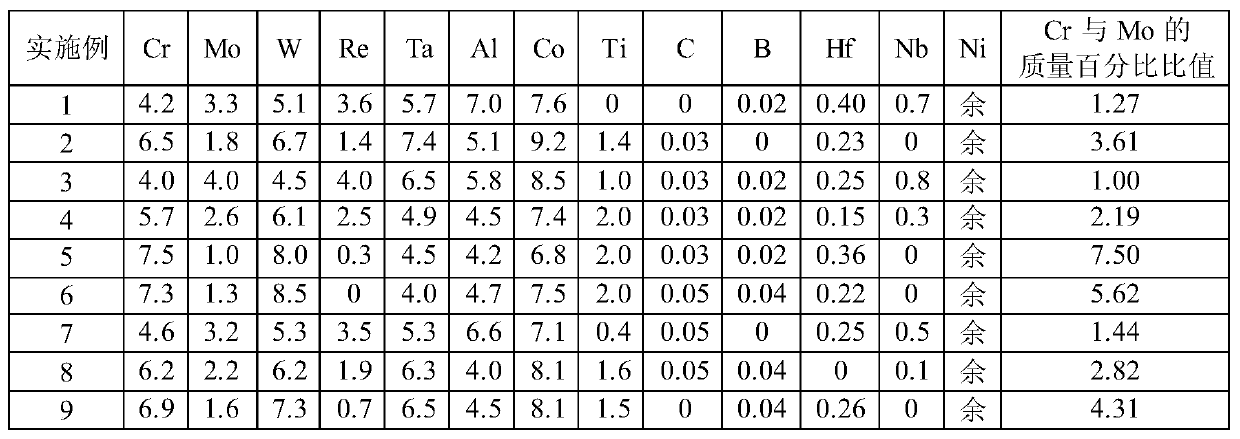

[0028] The chemical composition of embodiment 1-11 alloy

[0029] The mass percent of the chemical composition of the alloy is: Cr 3.5-7.5%, Mo 1.0-4.0%, W 4.5-8.5%, Re 0-4.0%, Ta 4.0-8.0%, Al 4.0-7.0%, Co 6.8-9.2 %, Ti 0 to 2.0%, C 0 to 0.05%, B 0 to 0.04%, Hf 0 to 0.4%, Nb 0 to 1%, Ni as the balance; the chemical composition of Cr, Mo, W, B and Hf in the alloy The composition is controlled as follows: 1.0≤Cr to Mo mass percentage ratio≤7.5, W 4.5~8.5%; wherein, when 1.0≤Cr to Mo mass percentage ratio≤2.0, W 4.5~6.0%, 0.25%≤B+Hf ≤0.44%; when 2.0<Cr to Mo mass percentage ratio≤4.0, W 6.0~7.0%, 0<B+Hf<0.25%; when 4.0<Cr to Mo mass percentage ratio≤7.5, W 7.0~ 8.5%, 0.25%<B+Hf≤0.44%. Table 2 shows the mass percentages of the chemical components of alloy examples 1-11 of the present invention.

[0030] Table 2 The mass percent of the chemical composition of alloy examples 1 to 11 of the present invention

[0031]

[0032]

Embodiment 1

[0034] The heat-resistant corrosion-resistant long-life superalloy involved in this embodiment uses the master alloy ingot with the chemical composition of Example 1 in Table 2 to cast directionally solidified single crystal gas turbine blades with a length of more than 300 mm.

[0035] The double vacuum induction method is used for smelting, according to the required chemical composition according to the ratio of ingredients, put into the vacuum induction melting furnace for smelting, the smelting process includes five steps of melting, refining, cooling, alloying and pouring; in the melting step, the nickel , chromium, molybdenum, tungsten, rhenium, tantalum, cobalt, and niobium are loaded into the crucible, and refined for 38-42 minutes after being melted, and the alloy liquid melt is stirred after refining, and then the power is turned off to cool down until the alloy liquid conjunctiva; power on again, add aluminum and Stir the alloy liquid melt after smelting for 18-20 mi...

Embodiment 2

[0037] The heat-resistant corrosion-resistant long-life superalloy involved in this embodiment adopts the master alloy ingot of the chemical composition in Example 2 in Table 2 to cast a hollow directionally solidified single crystal gas turbine blade with a length of more than 300 mm and a minimum wall thickness of 0.5 mm. .

[0038] The double vacuum induction method is used for smelting, according to the required chemical composition according to the ratio of ingredients, put into the vacuum induction melting furnace for smelting, the smelting process includes five steps of melting, refining, cooling, alloying and pouring; in the melting step, the nickel , chromium, molybdenum, tungsten, rhenium, tantalum, cobalt, and carbon are loaded into the crucible, and refined for more than 38 to 42 minutes after refining. After refining, the alloy liquid melt is stirred, and then the power is turned off to cool down until the alloy liquid conjunctiva; After smelting with titanium for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com