Novel pneumatic automatic dust blowing and liquid suction device

An automatic and new technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of uneven liquid concentration, low production efficiency, high labor intensity, etc., to reduce labor intensity and occupy space Small, improve the effect of environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

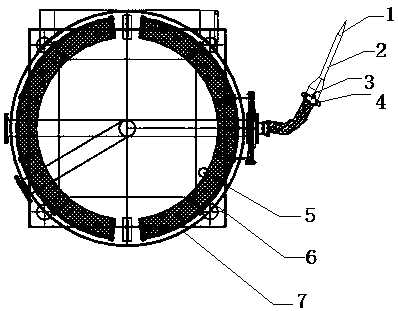

[0012] This embodiment provides a new type of pneumatic automatic soot-blowing and liquid-absorbing device, which is characterized in that: the new type of pneumatic automatic soot-blowing and liquid-absorbing device includes a suction head (1), an ash inlet hose (2), a female connector (3 ), non-male connector (4), vent pipe (5), filter screen (6), upper barrel (7);

[0013] Among them: there is a vent pipe (5) inside the upper barrel (7), a filter screen (6) is arranged on the vent pipe (5), and a non-male joint (4) is arranged on one side of the upper barrel (7). The non-male joint (4) is connected to the non-female joint (3), and the non-female joint (3) is connected to the ash inlet hose (2), and the end of the ash inlet hose (2) is provided with a suction head (1).

[0014] The suction head (1) is made of steel, the front end of the suction head (1) is tapered, and small holes of the same size are evenly arranged on the front end of the suction head (1), and the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com