Helical gear time-varying mesh stiffness calculating method based on finite element analysis

A technology of time-varying meshing stiffness and calculation method, applied in the direction of calculation, components with teeth, belts/chains/gears, etc., can solve the problems of time-varying meshing stiffness of helical gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

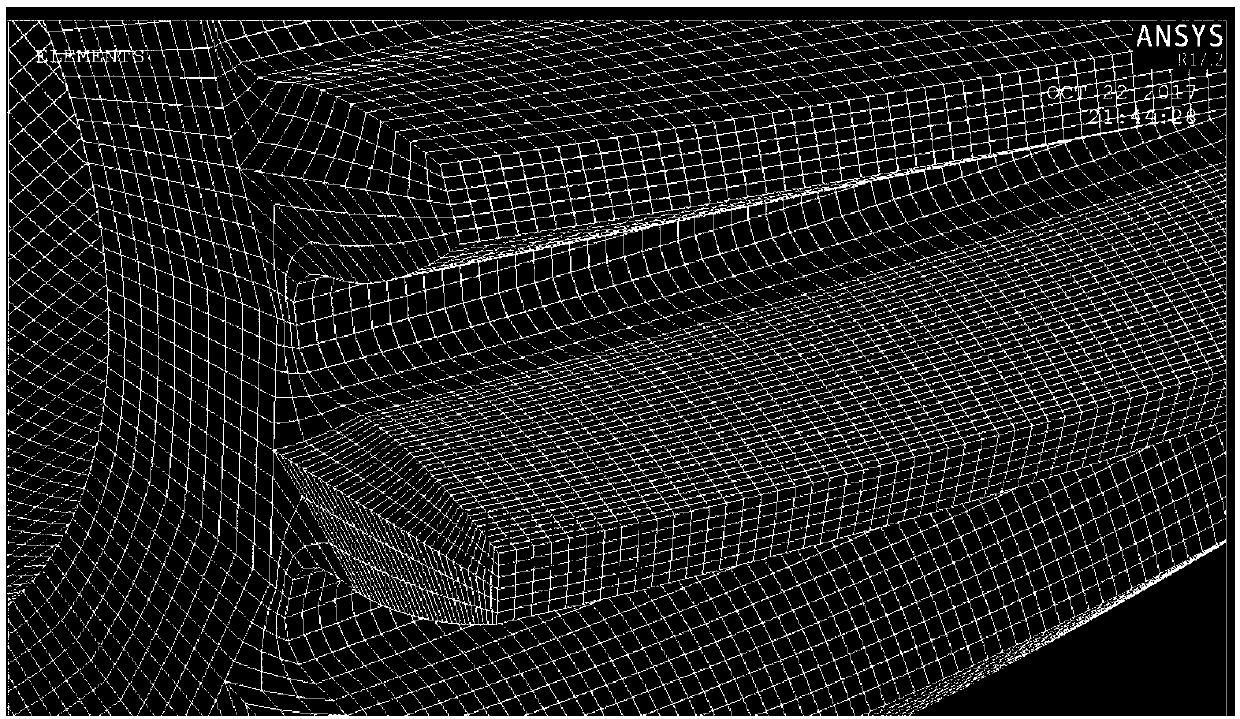

[0059] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

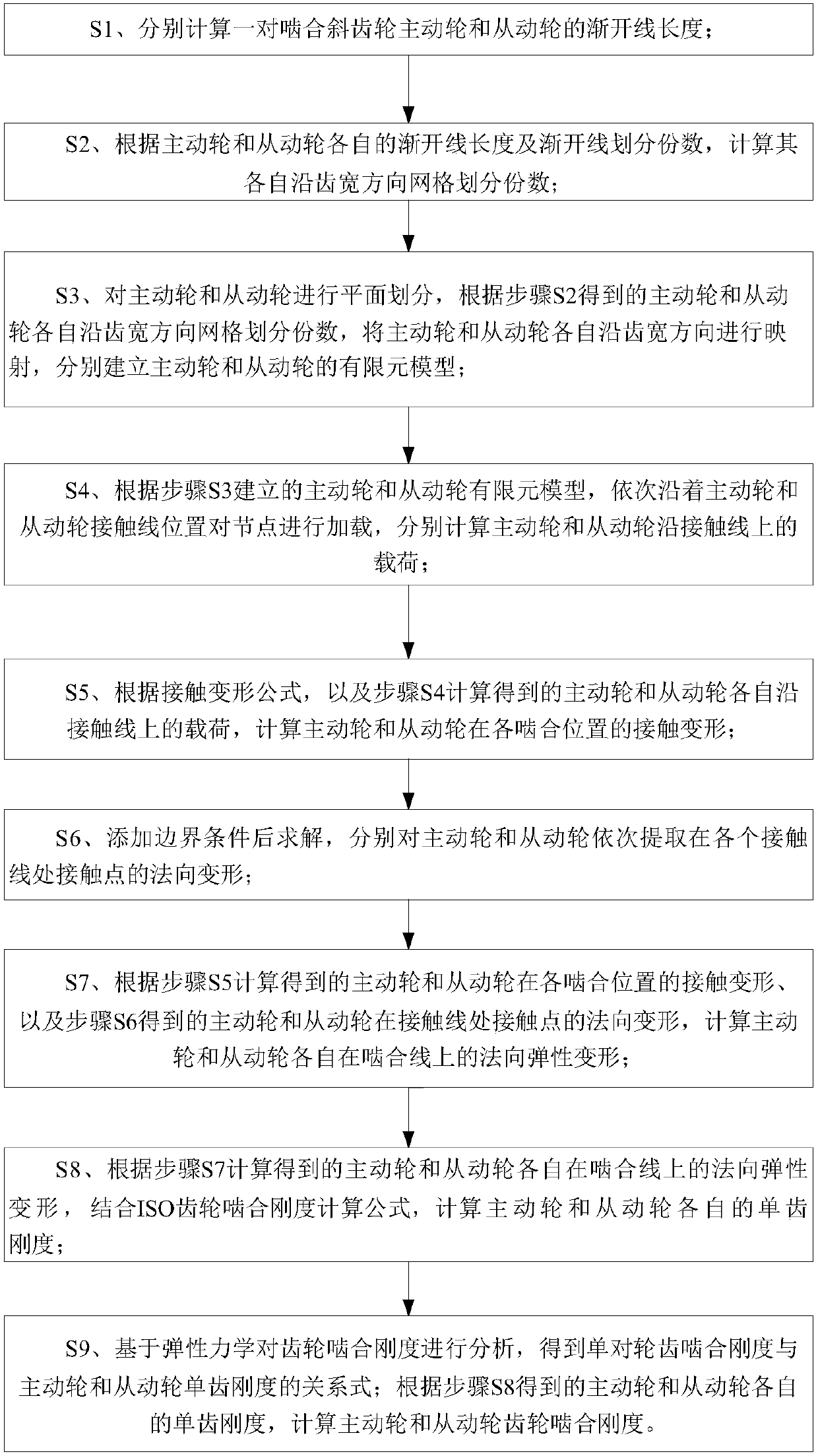

[0060] Such asfigure 1 Shown is the scheme flow chart of the present invention, the technical scheme of the present invention is: a kind of time-varying meshing stiffness calculation method of helical gears based on finite element analysis, comprising:

[0061] S1. Calculate the involute lengths of a pair of meshing gear driving wheels and driven wheels respectively; the specific calculation process is as follows:

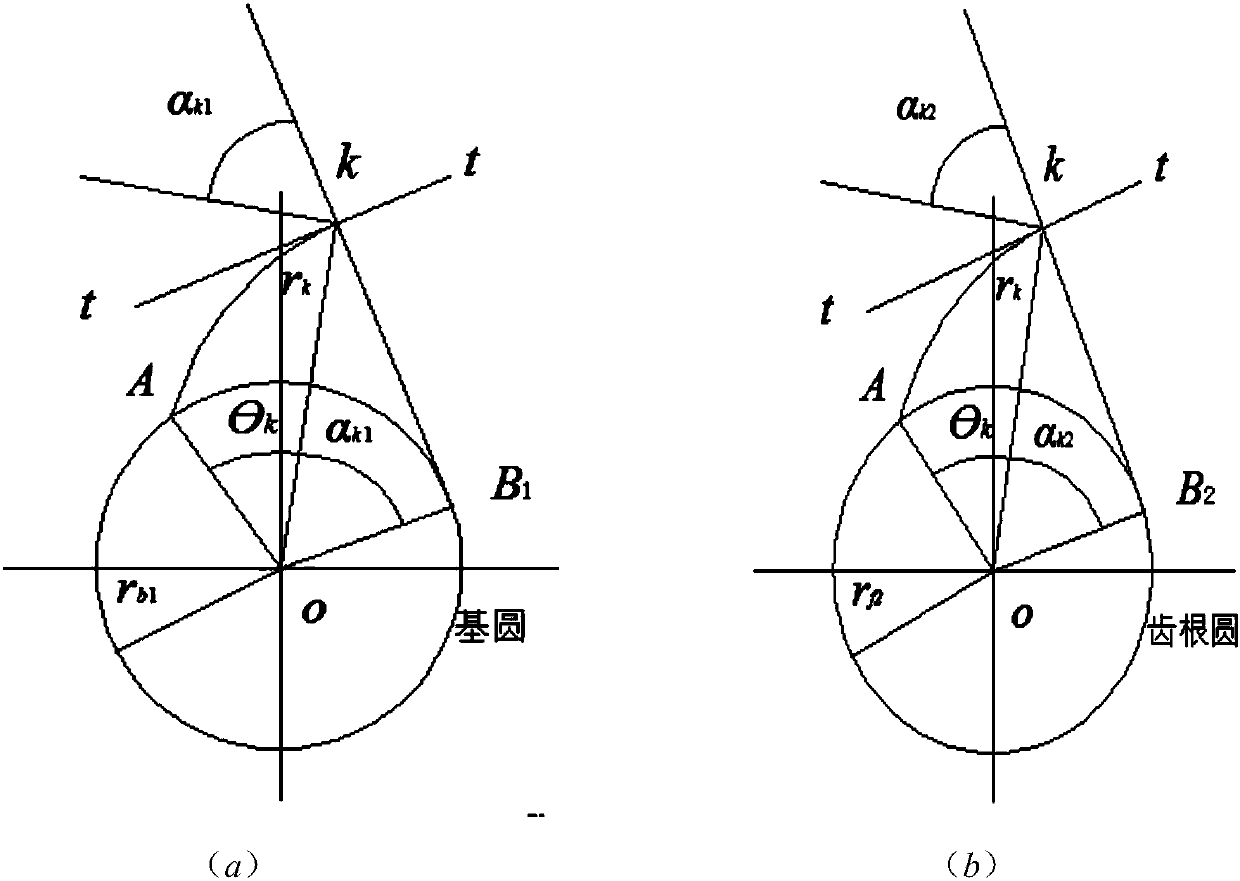

[0062]

[0063] θ k =(tanα k -α k ) (2)

[0064] where r b is the base circle radius; θ k is the spread angle at point k on the involute line, r k is the distance from the center of the circle to point k on the involute line, α k is the pressure angle on the involute; s is the length of the gear involute.

[0065] The calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com