Cryogen-free magnet system with a heatsink connected to the gas circuit of a cryo cooler

A technology of coolers and coolants, applied in the direction of coolers, refrigerators, magnetic objects, etc., can solve expensive problems, achieve simple but effective use, and prolong TTQ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

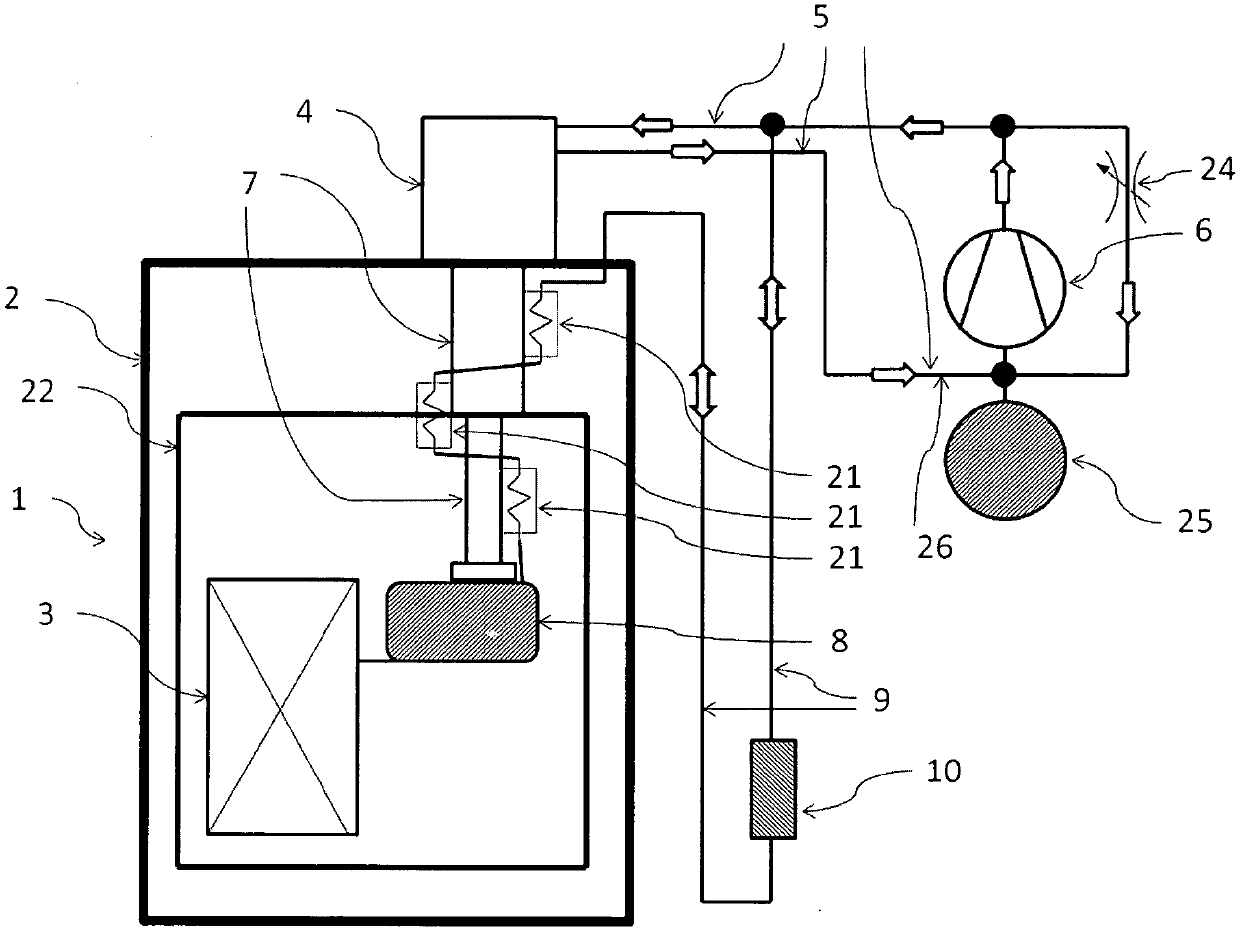

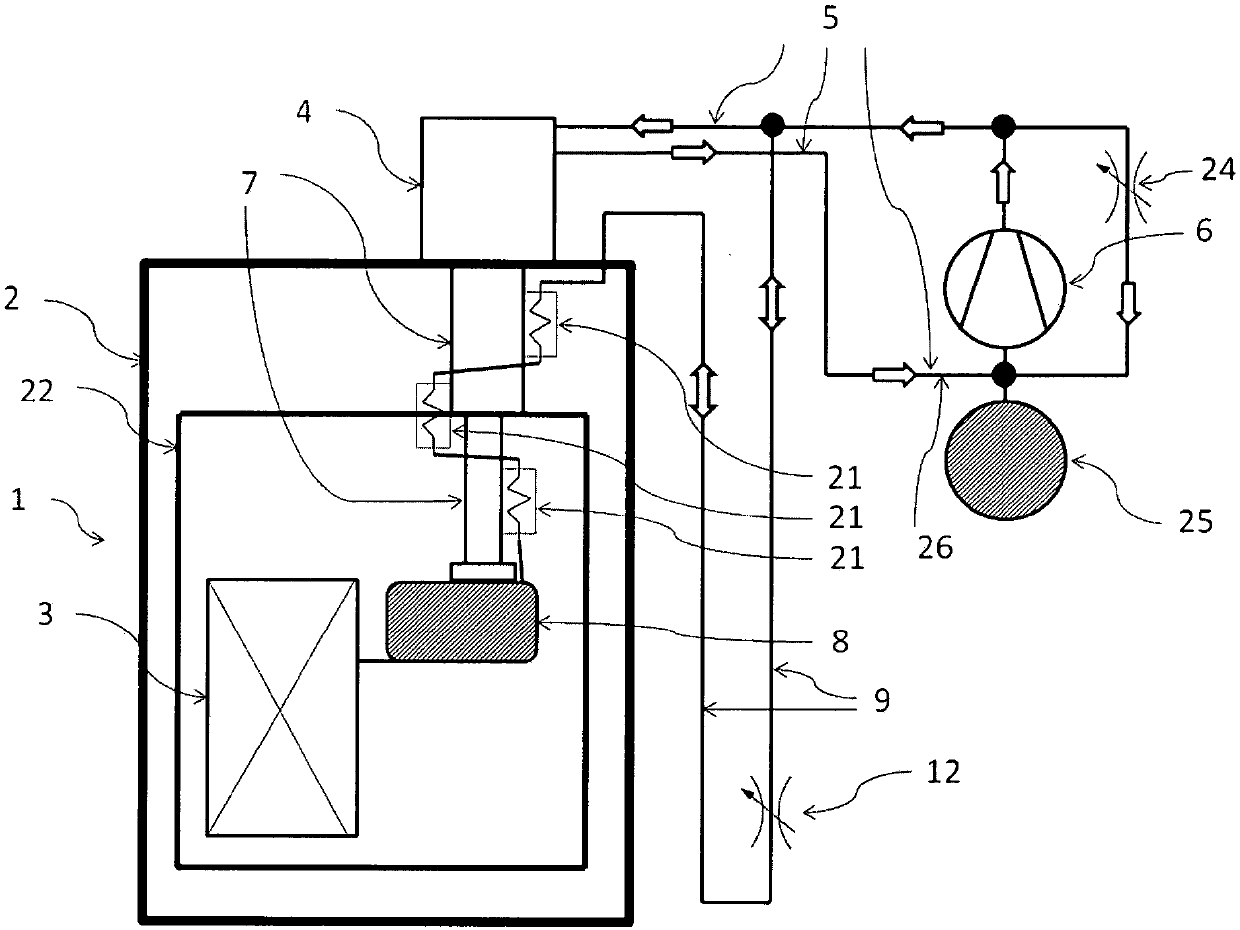

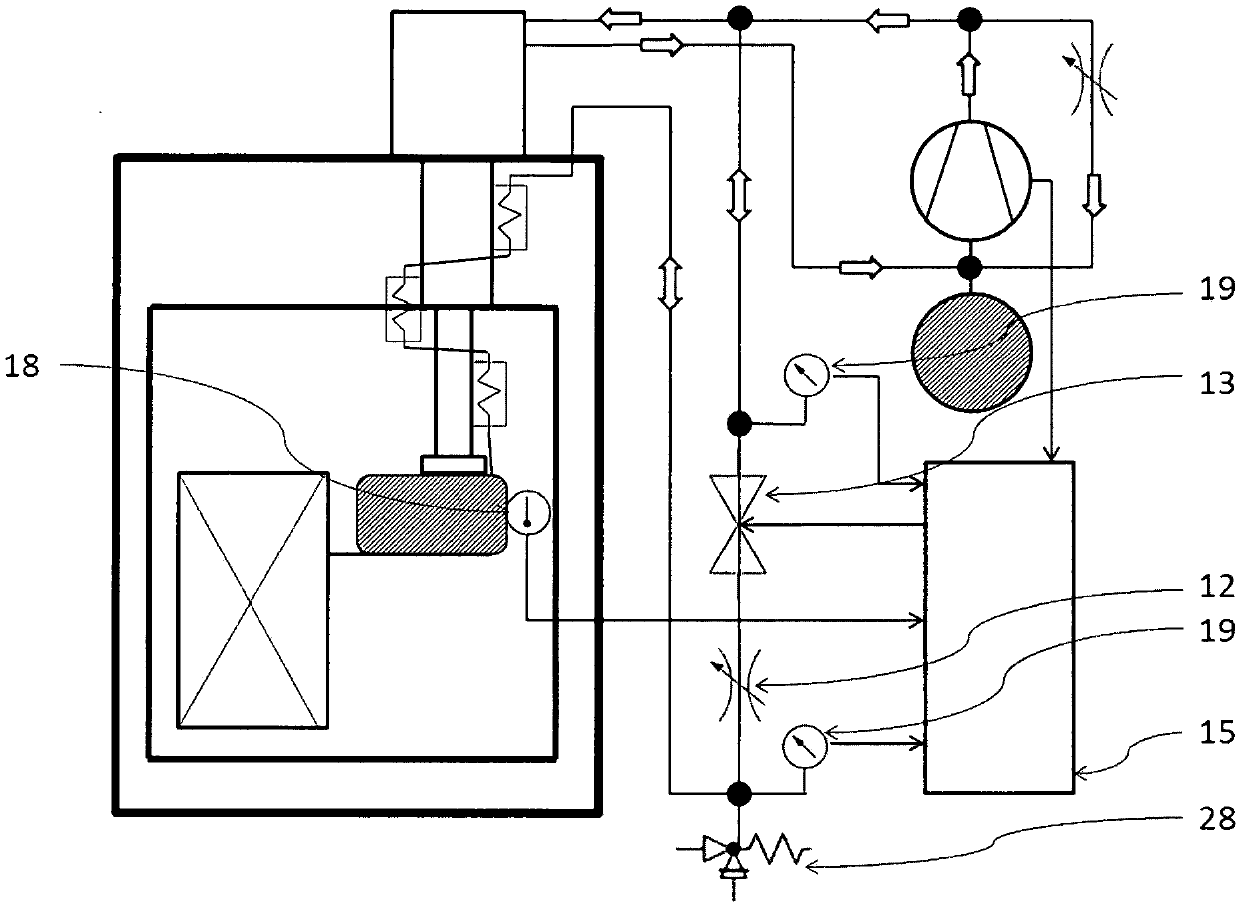

[0049] A conventional configuration of an actively cooled superconducting magnet system consists of a superconducting magnet (or magnet coil) in an insulating vacuum cooled by a second stage of a cryocooler. The first stage is used to cool the radiation shield (not shown here). This cold head is connected to a compressor which compresses helium from approximately 5-10 bar to 20-25 bar during operation. Subsequently, this helium drives the cold head.

[0050] Such as figure 1 In a cryostat arrangement 1 of this type shown in , the superconducting magnet coil system 3 to be cooled is arranged in a vacuum chamber 2 provided with a cryocooler which actively cools the cryostat Arrangement 1 and comprising a coolant circuit 5 comprising a compressor 6 and a coldhead 4 having a chiller finger 7 which is at least single stage, and Two-stage in the illustrated embodiment, and in thermal contact with the superconducting magnet coil system 3, the volume vessel 8 containing the cryogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com