Water cooling device for roller below induction furnace

A water-cooled roller and induction furnace technology, applied in the field of induction furnaces, can solve the problems of roller shaft deformation, impact on service life, damage, etc., and achieve the effect of prolonging service life, simple and reasonable structure design, and realizing continuous use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

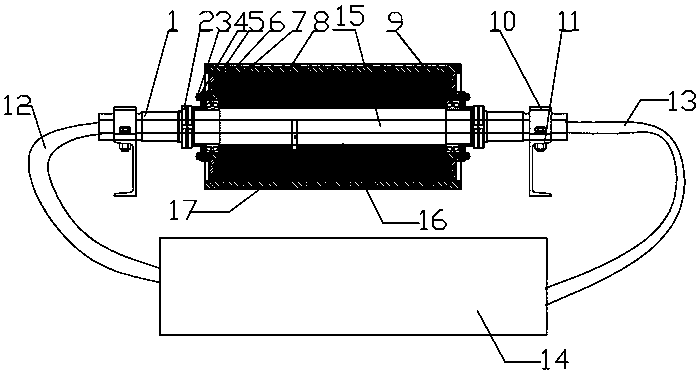

[0013] like figure 1 As shown, a water-cooled roller device under an induction furnace includes a roller shaft 1, a reel 8, a pressure roller seat 10, a reinforced angle steel 11, a water cooling circulation device 14, a cooling cavity groove 15, a threaded protrusion 16 and a threaded groove 17. The roller shaft 1 is sleeved in the reel 8 and extends to both sides. The outer surface of the roller shaft 1 is provided with a threaded protrusion 16, and the reel 8 is provided with a threaded groove 17. The threaded The protrusion 16 is connected to the threaded groove 17 in a rotationally separated manner, and the two sides of the roller shaft 1 are provided with a pressure roller seat 14, and a reinforced angle steel 15 is installed under the pressure roller seat 14 and is connected by welding. The roller shaft 1 is equipped with a cooling chamber groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com