Steel pipe magnetic powder flaw detection imaging detection system and steel pipe magnetic powder flaw detection imaging detection method

A magnetic particle flaw detection and imaging detection technology, which is applied in the direction of material magnetic variables, can solve problems such as lack of concentration, information flow disorder, and operational errors, and achieve the effects of increasing production output, high labor intensity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

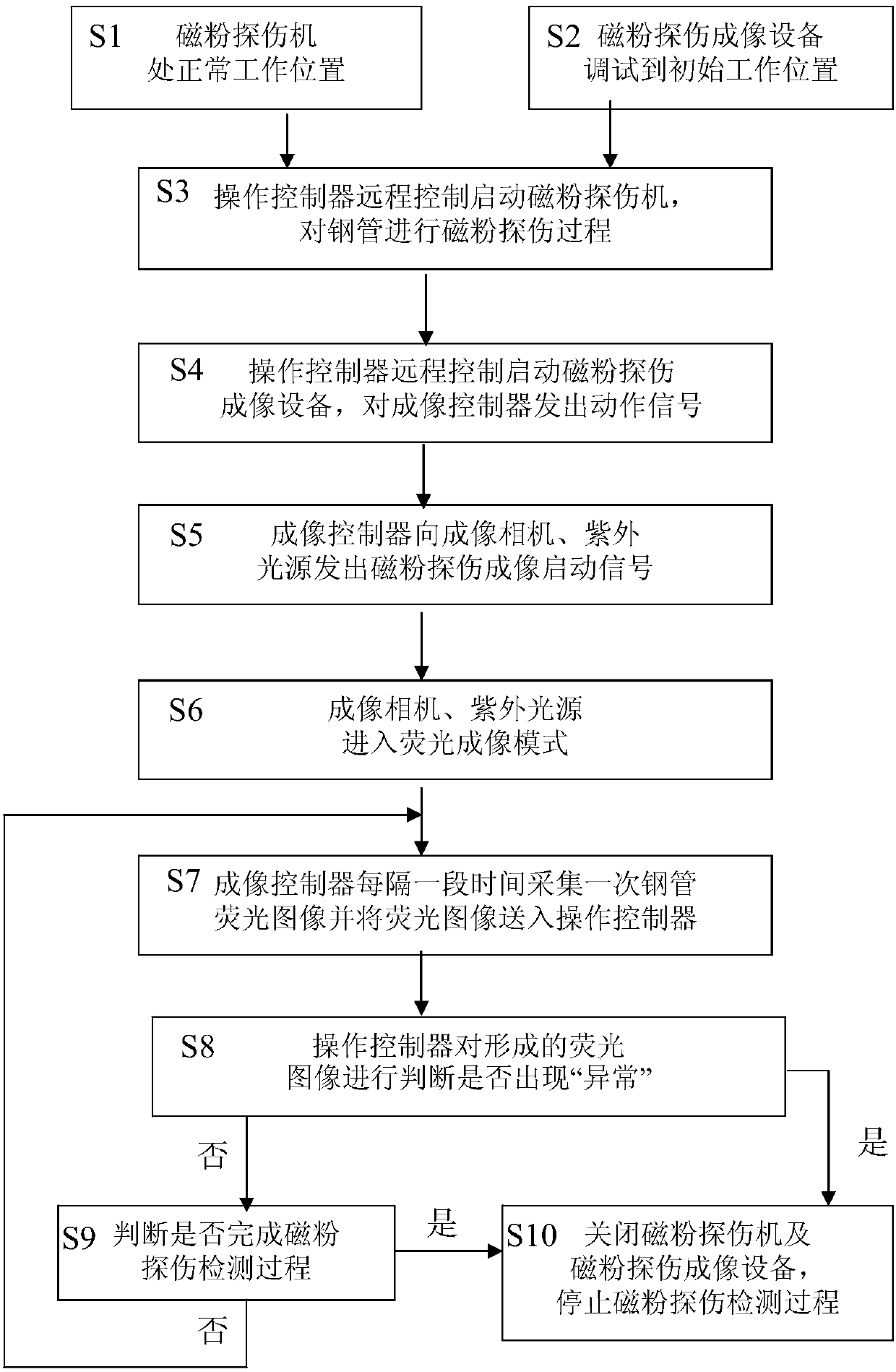

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

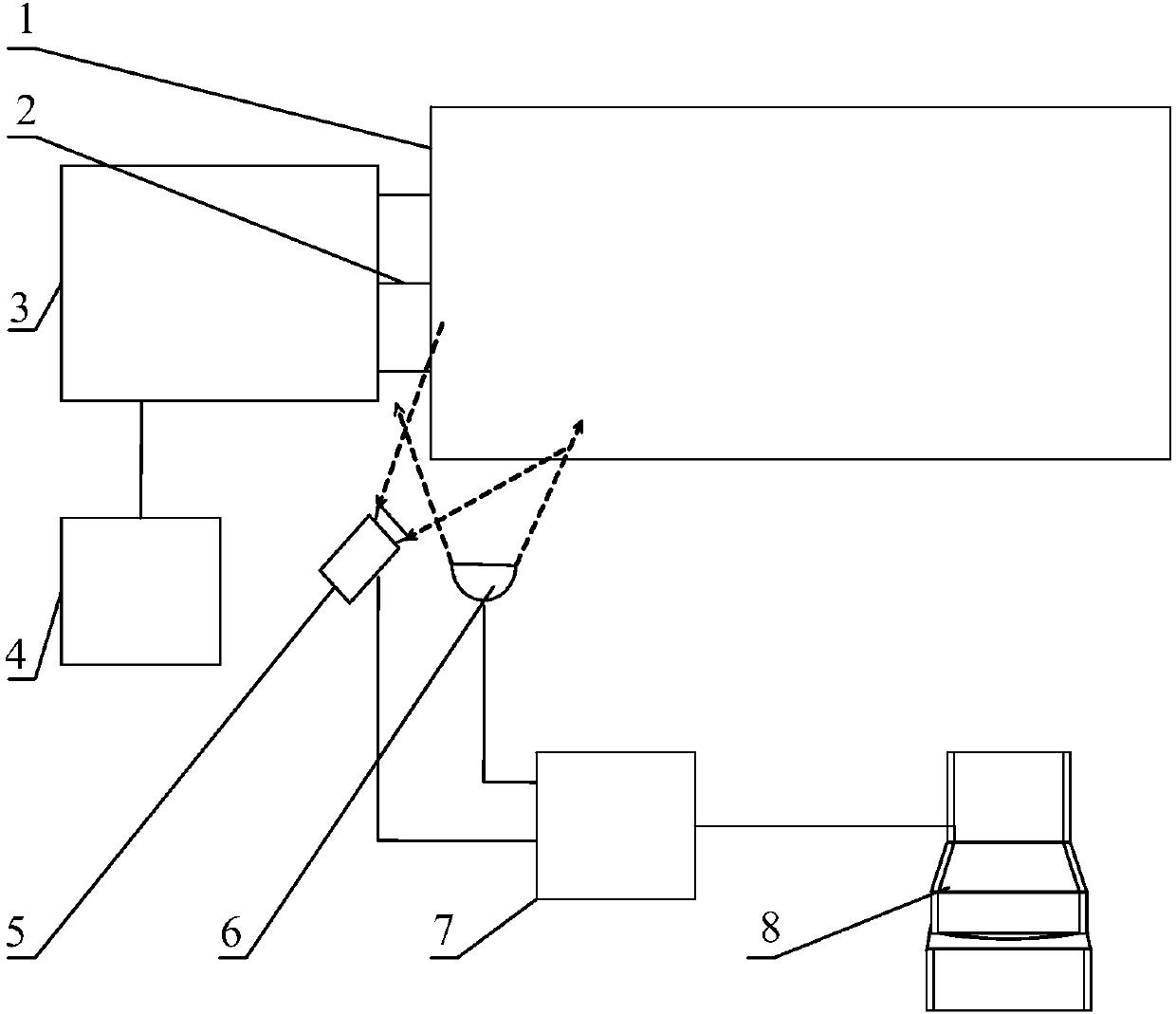

[0036] see figure 1 , the steel pipe magnetic particle flaw detection imaging detection system of the present invention includes:

[0037] Magnetic particle flaw detection machine, which is the prior art, is composed of flaw detection machine mechanical movement equipment 3, magnetic particle spraying equipment 2 and flaw detection machine controller 4, wherein the flaw detection machine controller 4 controls the flaw detection machine mechanical movement equipment 3, magnetic particle spraying equipment 2 and the action of the steel pipe 1, and spray the magnetic suspension liquid on the steel pipe 1.

[0038] Magnetic particle flaw detection imaging equipment, which is equipment for fluorescent imaging detection of steel pipes, is composed of an imaging camera 5, an ultraviolet light source 6, and an imagin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap