Optical element arrangements for varying beam parameter product in laser delivery systems

A technology of optical components, light beams, applied in the field of laser systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

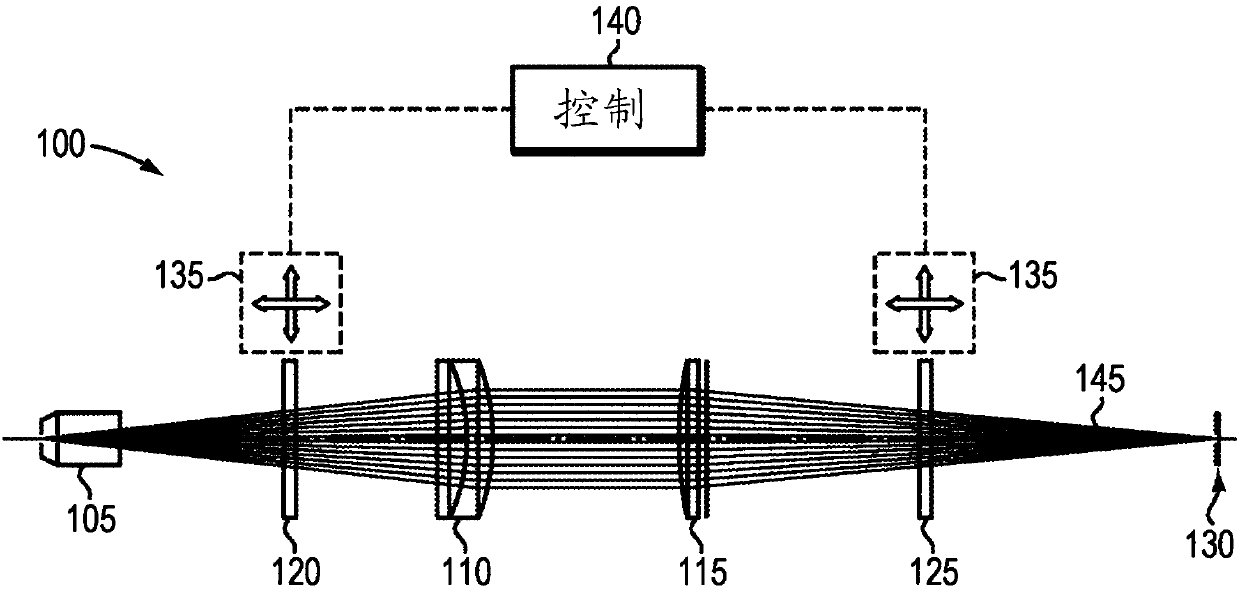

[0057] figure 1 Depicted is a schematic diagram of a laser beam delivery system 100 including beam steering optics according to an embodiment of the invention. In various embodiments, the laser beam delivery system 100 may be disposed within a laser-based cutting or welding head, for example. Beam delivery system 100 is characterized by connection to a laser generation system (e.g. not in figure 1 Beam delivery fiber terminating at fiber end cap 105 , collimating lens 110 , focusing lens 115 , and optical element 120 between end cap 105 and collimating lens 110 of the remainder of the WBC laser system shown in . In various implementations, the optical element 120 is positioned close to the fiber end cap 105 to minimize the size of the light beam impinging on the optical element 120 . Refraction of smaller beams can be performed using optics with smaller geometry and can change the output profile with higher sensitivity. figure 1 Also depicted is an optional second optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com