Novel high-speed blender

A wall breaking machine, a new type of technology, applied in home appliances, applications, kitchen utensils, etc., can solve the problems of waste of resources, small gap between bearing and shaft core, high energy consumption, etc., achieve convenient lubrication and maintenance, prolong dry grinding time, The effect of high running precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

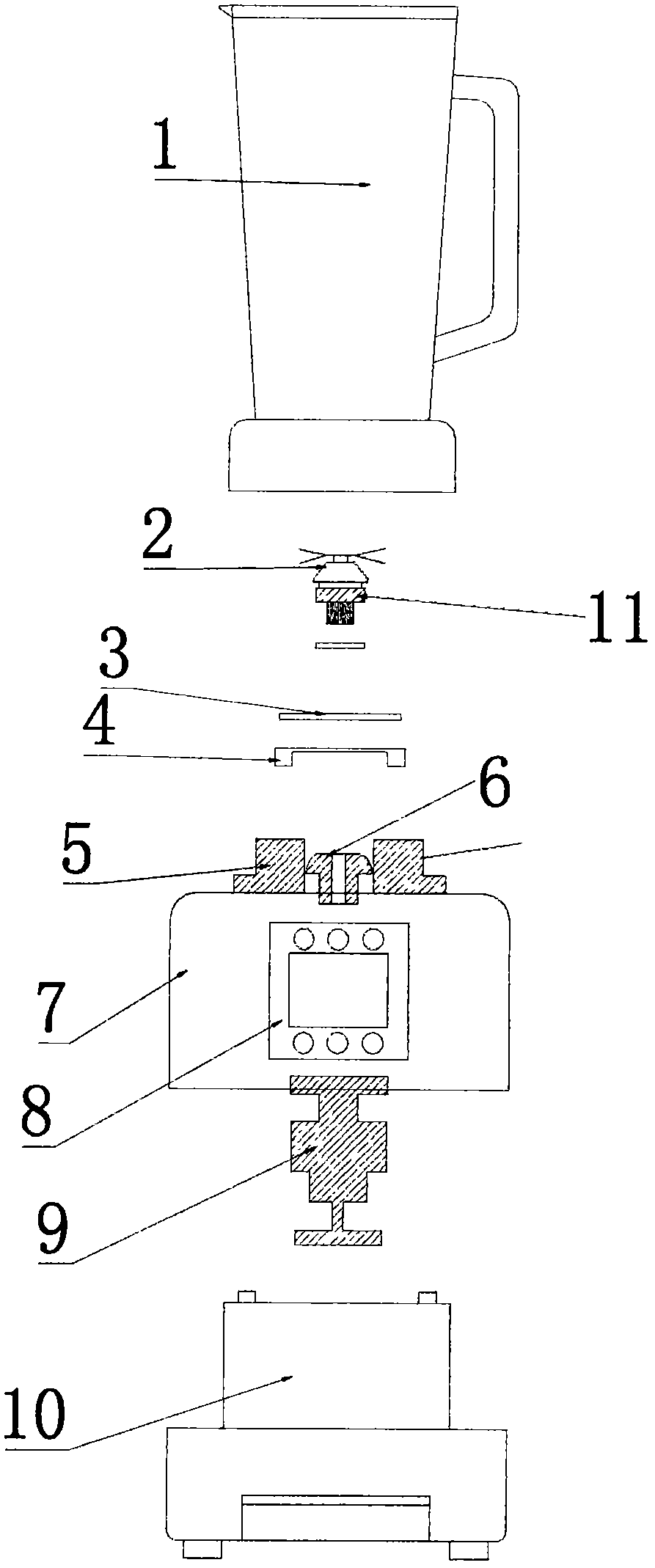

[0019] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

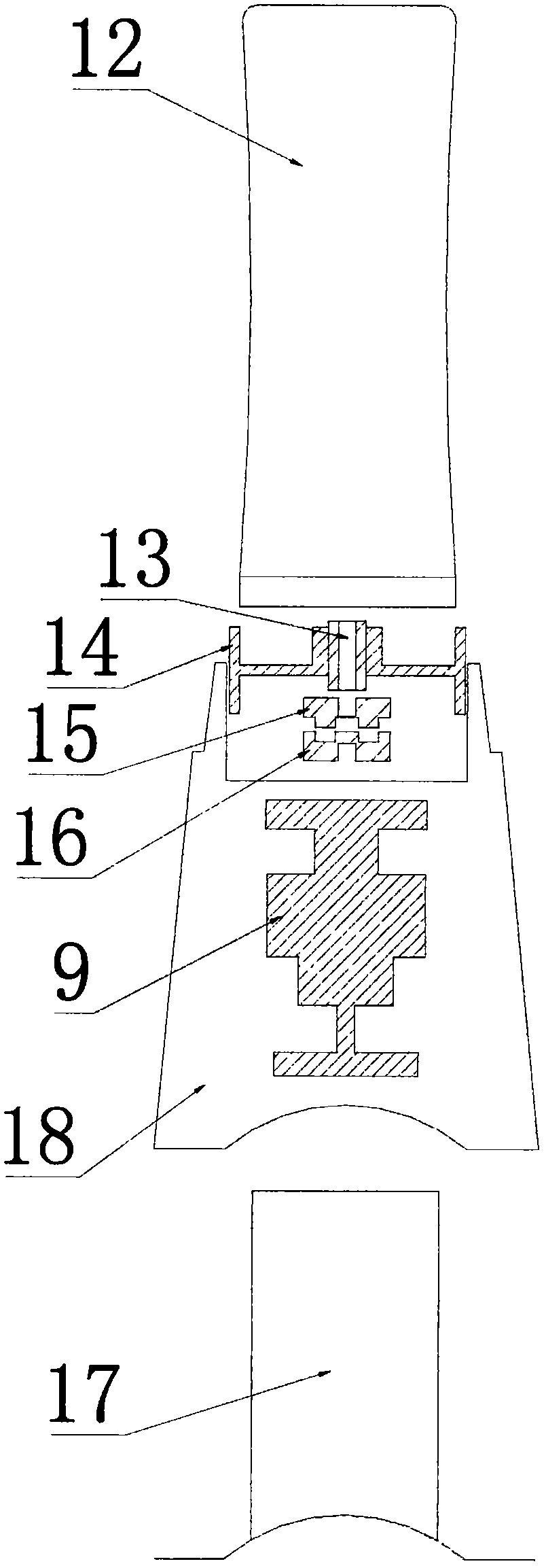

[0020] figure 2 This is an exploded view of a traditional wall breaking machine. The traditional wall breaking machine includes a motor 9. The horsepower of the motor 9 is 25. The upper side of the motor 9 is equipped with a host upper cover 18, and the lower side of the motor 9 is equipped with a host lower cover 17 and a host upper cover. 18 is equipped with a knife holder 14 on the upper side, an oil bearing 13 is installed at the center of the knife holder 14, an oil seal is arranged on the oil bearing 13, and the oil seal is made of silicone; the lower side of the knife holder 14 is provided with an upper sensor 15, and the lower side of the upper sensor 15 A lower sensor 16 is provided, and the upper sensor 15 and the lower sensor 16 are snap-connected, and the upper sensor 15 and the lower sensor 16 are made of plastic.

[0021] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com