Water electrolytic descaling tank allowing negative electrode steel mesh to be fast changed

A cathode and stencil technology, applied in descaling and water softening, water/sewage treatment, water/sewage treatment equipment, etc., can solve time-consuming and labor-intensive problems, achieve low cost, shorten downtime, and improve descaling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

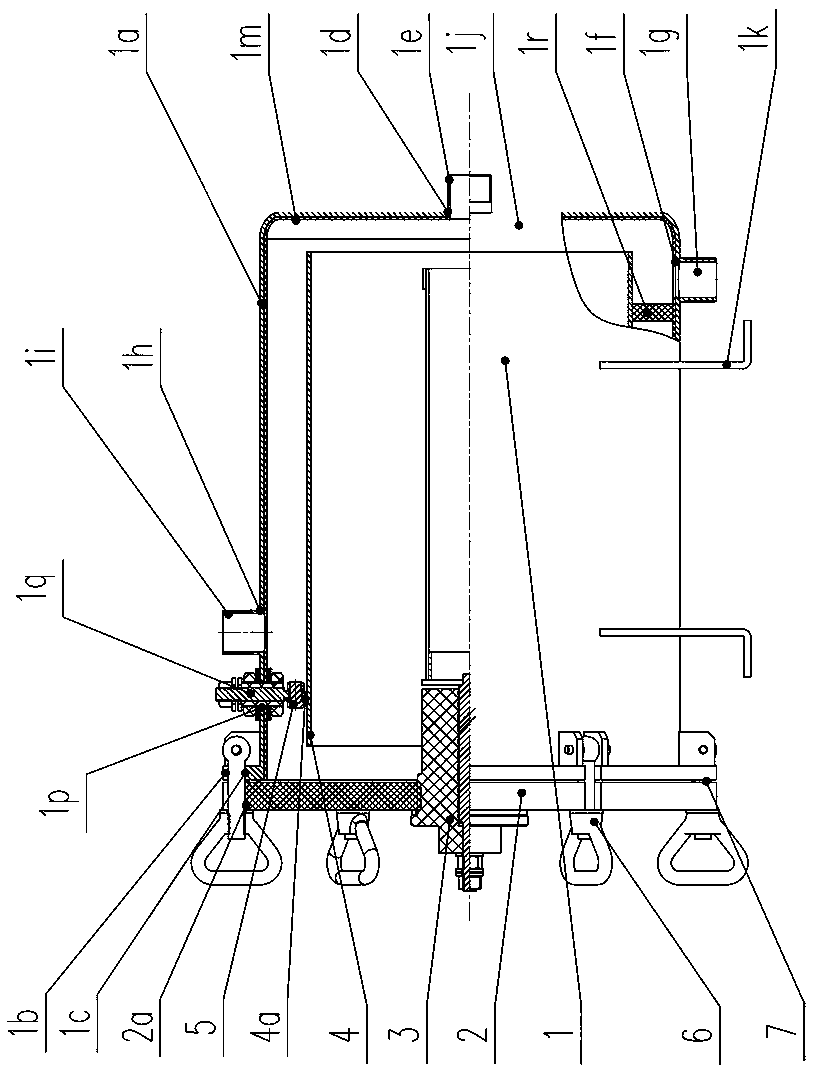

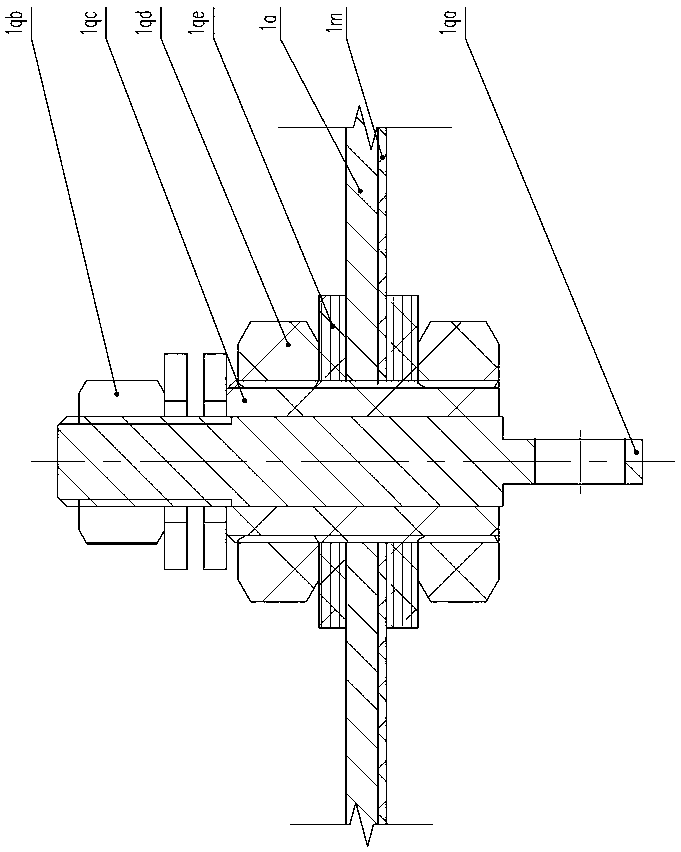

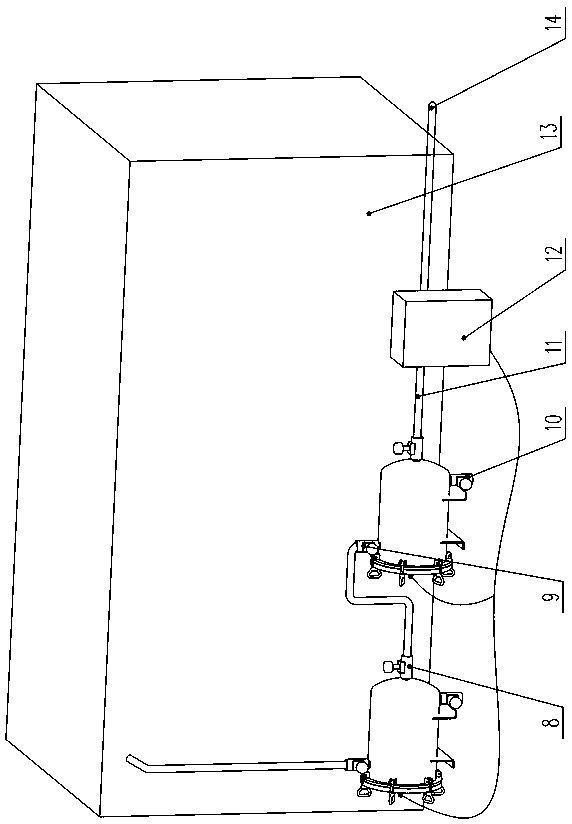

[0007] Specific implementation: such as figure 1 , figure 2 , image 3 In the illustrated embodiment, the assembled one-inch water outlet pipe (1i) of the present invention is concentrically screwed with a one-inch water outlet valve (9), and connected to the water system (13) with a one-inch water pipe (11); Screw the one-inch water inlet pipe (1e) concentrically on the one-inch water inlet valve (8) and connect it with the one-inch water pipe (11) and the water supply pipe (14) of the water supply system; the one-inch drain Screw the one-inch drain valve (10) concentrically on the tube (1g); connect the positive output DC power supply of the electric control box (12) with the anode rod and the wiring assembly (3); then connect the electric control box (12) Connect the negative pole of the output DC power supply to the cathode terminal assembly (1q) at the upper left end of the horizontal cylinder (1a); after connecting the two assembled sets of the invention in series, close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com