Permanent magnet brushless motor

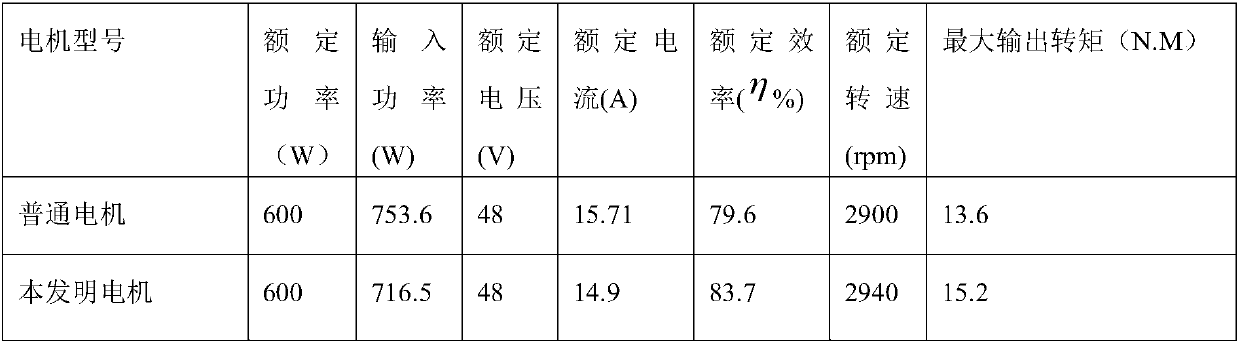

A permanent magnet brushless motor and rotor technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of large DC impedance of the coil, large span of copper wire at the end of the stator, and waste of copper, etc. Achieve the effects of small noise and torque fluctuation, optimized armature diameter and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

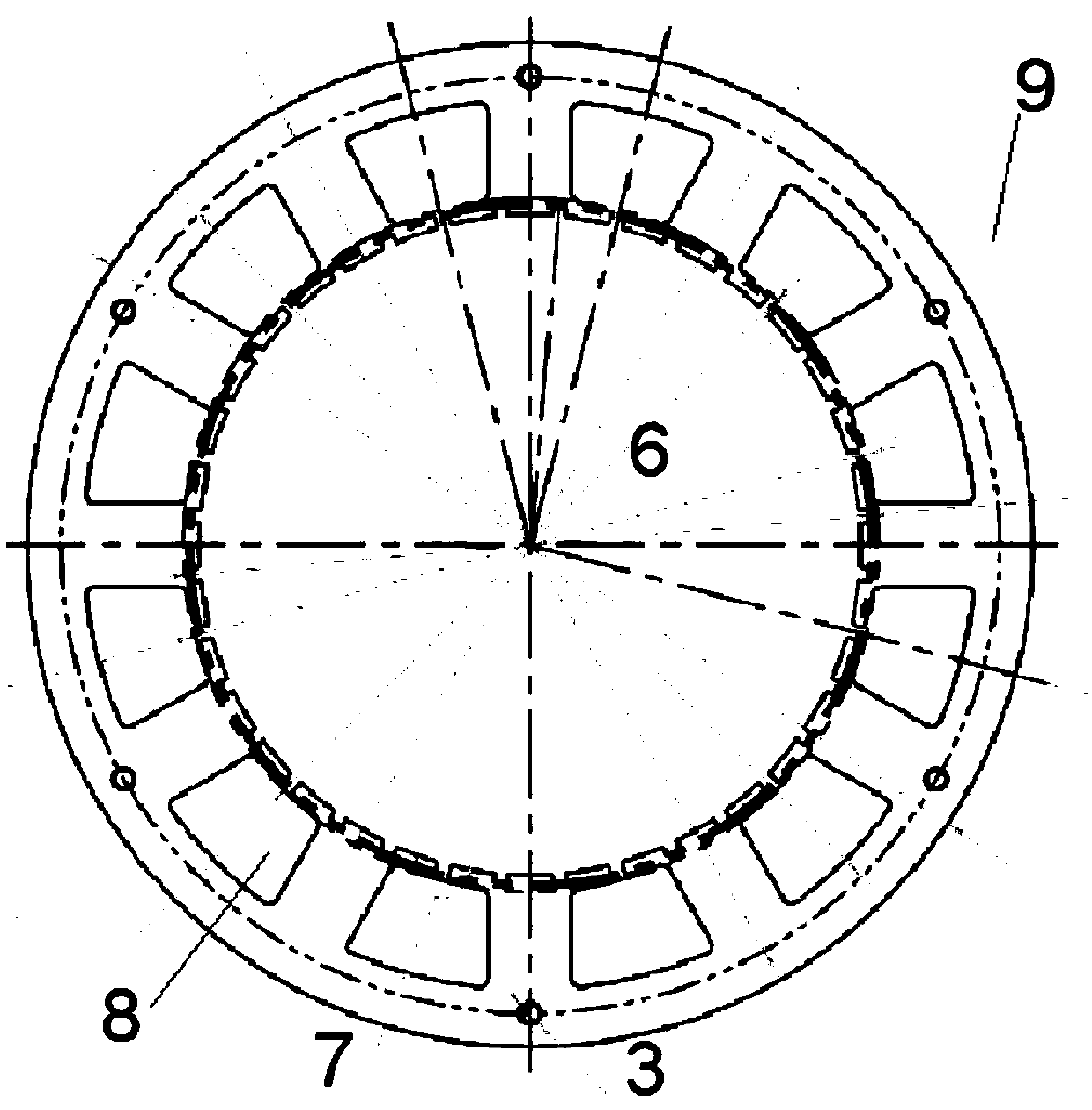

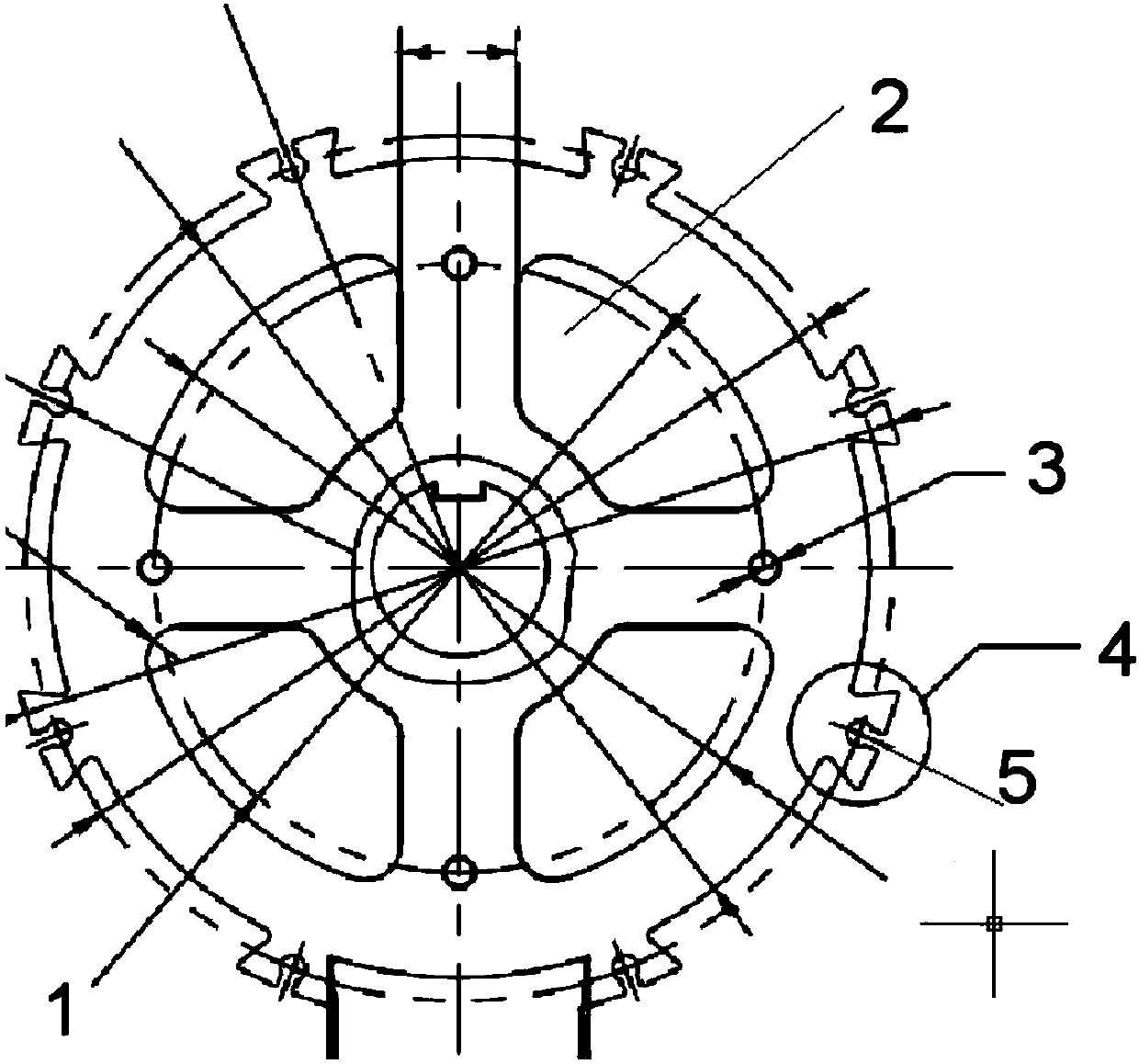

[0017] A permanent magnet brushless motor, comprising a motor housing, a rotor and a stator. The rotor is formed by superimposing rotor punching pieces with a diameter of 78mm. The stator is superimposed by stator punching pieces. The diameter is 120mm. The rotor punching piece is provided with a shaft hole 1 from the inside to the outside. The shaft hole diameter is 15mm, the heat dissipation hole 2, the rotor mounting hole 3 and the protruding teeth 4. The number of protruding teeth is 8, and the protruding teeth are 4. The distance between the two is 21mm, the center of the tooth 4 is also provided with a circular slot 5, the opening width of the circular slot is 1.5, and the diameter of the circular hole is 2.2mm. The stator punching piece is provided with rotor holes 6 in sequence from the inner to the outer ring, The diameter of the rotor hole is 79mm, the slot 7, the winding slot 8 and the stator mounting hole 9, and the width of the slot 7 is 1.67mm.

[0018] The said sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com