Processing method of frozen fish after thawing

A processing method and technology for freezing fish, which are applied in the direction of preservation of meat/fish by freezing/cooling, the function of food ingredients, preservation of meat/fish with chemicals, etc., can solve the problem of reducing the freshness, taste and nutritional content of fish soup, and the ease of use. Deterioration and other problems, to achieve the effect of delicious and rich taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

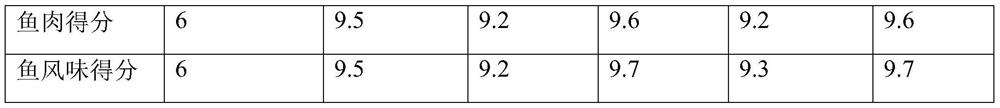

Examples

Embodiment 1

[0026] The present embodiment provides a kind of processing method after thawing of frozen fish, comprising the following steps:

[0027] (1) configure a fresh-keeping solution at normal temperature, which includes trisodium phosphate, 0.5% lemon slices, 1% sucrose and 0.1% salt with a mass percentage concentration configuration concentration of 5.5% in the fresh-keeping solution, and the lemon slices are placed in the The time in the fresh-keeping solution is longer than 2h.

[0028] (2) After the fish is slaughtered, first clean it with running water, then use the fresh-keeping solution to circulate and impregnate the fish body for 15 minutes, wherein the flow rate of the fresh-keeping solution is 5m / s, and then circulate the fish body under vacuum condition Flow immersion for 5 minutes, so that the pH value of the fish body is 7.

[0029] (3) Place the fish body soaked in the fresh-keeping solution in liquid nitrogen for 2 seconds, then freeze at -80°C for 20 minutes, and ...

Embodiment 2

[0035] A method for processing frozen fish after thawing, comprising the steps of:

[0036] (1) configure a fresh-keeping solution at normal temperature, which includes trisodium phosphate, 20% lemon slices, 20% sucrose and 10% salt with a mass percentage concentration configuration concentration of 6%, and the lemon slices are placed in the fresh-keeping solution. The time in the fresh-keeping solution is longer than 2h.

[0037] (2) After the fish is slaughtered, first clean it with running water, and then use the fresh-keeping solution to circulate and impregnate the fish body for 30 minutes, wherein the flow rate of the fresh-keeping solution is 10m / s, and then circulate the fish body under vacuum condition Flow immersion 10 minutes, make the pH value of fish body be 9.

[0038] (3) The fish body soaked in the fresh-keeping solution was placed in liquid nitrogen for 3 seconds, then frozen at -60°C for ~30min, and then stored at -15°C.

[0039] (4) Take a new fresh-keepin...

Embodiment 3

[0044] A method for processing frozen fish after thawing, comprising the steps of:

[0045] (1) Preserving solution is configured at normal temperature, which contains trisodium phosphate, 10% lemon slices, 11% sucrose and 5% salt with a mass percentage concentration configuration concentration of 5.6% in the fresh preserving solution, and the lemon slices are placed in the The time in the fresh-keeping solution is longer than 2h.

[0046] (2) After the fish is slaughtered, first use running water to clean it, then use the fresh-keeping solution to circulate and impregnate the fish body for 18 minutes, wherein the flow rate of the fresh-keeping solution is 8m / s, and then circulate the fish body under vacuum condition Flow immersion for 7 minutes, so that the pH value of the fish body is 8. The vacuum degree under the vacuum condition is -0.05MPa, and the fish body is always located in the fresh-keeping solution during the cyclic immersion process.

[0047] (3) The fish body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com