A kind of fermented collagen peptide and preparation method thereof

A collagen peptide and fermentation broth technology, applied in food science and other directions, can solve the problems that consumers are unacceptable, the collagen peptide is bitter and fishy, and has poor palatability, and achieves good palatability, removal of fishy smell, The effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

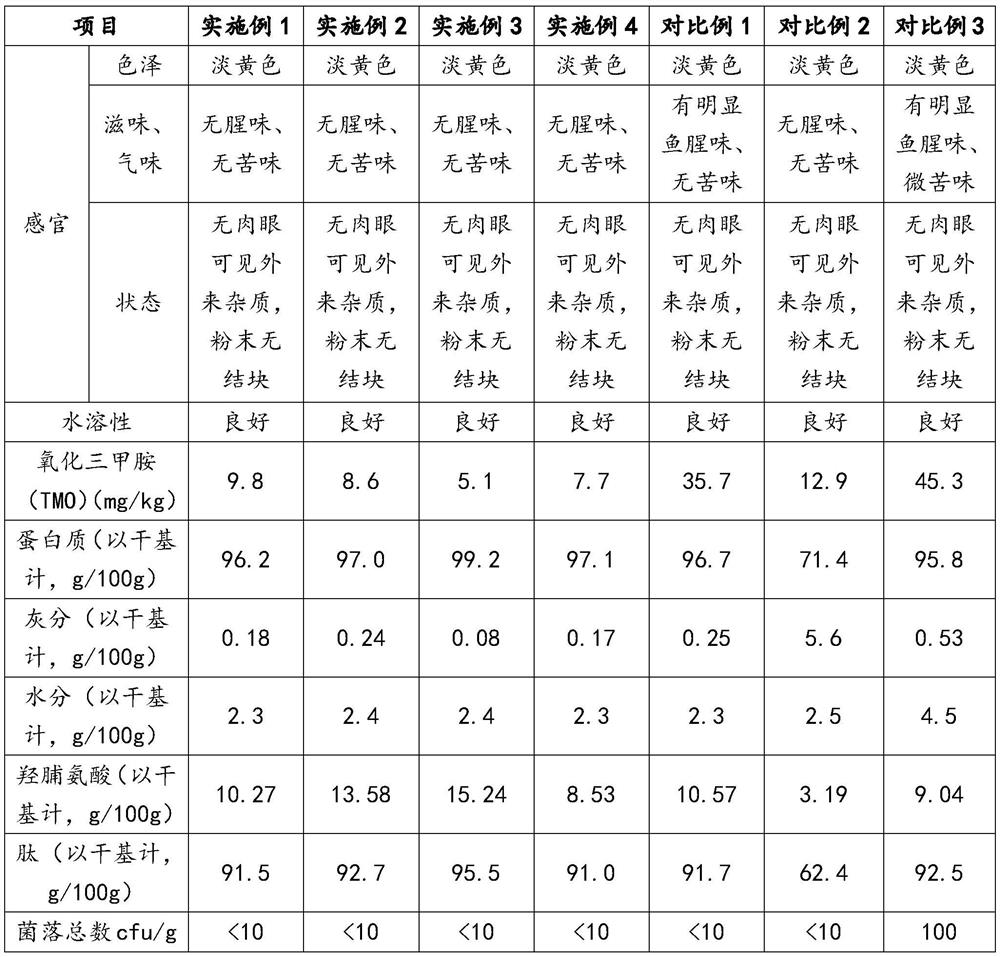

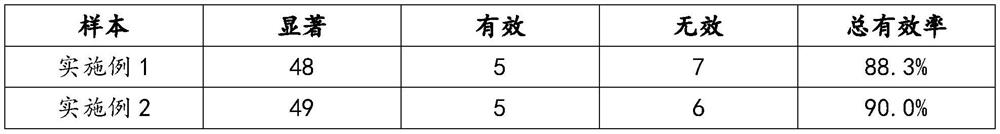

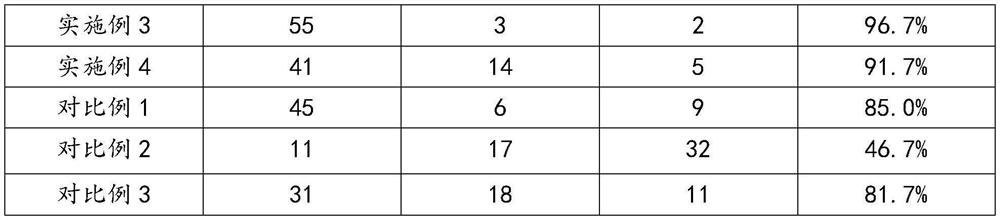

Examples

Embodiment 1

[0023] Weigh 2g of black tea powder and 2g of perilla powder, add 1000mL of water, boil and extract for 25min, filter to obtain plant extract;

[0024] Soak tilapia fish skin and plant extract at a ratio of 1:1 for 1 hour, drain and set aside;

[0025] Add distilled water according to the weight ratio of material to liquid 1:8, and beat with a beater;

[0026] The slurry after beating was placed in a colloid mill for homogenization to obtain uniform tilapia fish skin slurry, which was pumped to a high-voltage pulsed electric field treatment chamber through a peristaltic pump at a flow rate of 8mL / min, with an electric field intensity of 15KV / cm and a pulse frequency of 20Hz The pulse time is 1s for processing to obtain a high-voltage pulsed electric field (Pulsed Electric Fields, check PEF) treatment solution;

[0027] The obtained PEF treatment solution was treated at 121°C for 30 minutes to kill pathogenic bacteria, and then cooled to 35°C to obtain a liquid culture medium;...

Embodiment 2

[0033] Weigh 2g of black tea powder and 2g of perilla powder, add 1000mL of water, boil and extract for 25min, filter to obtain plant extract;

[0034] Soak tilapia fish skin and plant extract at a ratio of 1:1 for 1 hour, drain and set aside;

[0035] Add distilled water according to the weight ratio of material to liquid 1:8, and beat with a beater;

[0036] The beating slurry is placed in a colloid mill for homogenization to obtain a uniform tilapia skin slurry. Pumped to the high-voltage pulsed electric field treatment chamber through a peristaltic pump at a flow rate of 8mL / min, treated with an electric field intensity of 20KV / cm, a pulse frequency of 20Hz, and a pulse time of 1S to obtain a PEF treatment solution;

[0037] The obtained PEF treatment solution was treated at 121°C for 30 minutes to kill pathogenic bacteria, and then cooled to 35°C to obtain a liquid culture medium;

[0038] Inoculate the activated slant strain into the seed culture medium, ferment and cu...

Embodiment 3

[0043] Weigh 2g of black tea powder and 2g of perilla powder, add 1000mL of water, boil and extract for 25min, filter to obtain plant extract;

[0044] Soak tilapia fish skin and plant extract at a ratio of 1:1 for 1 hour, drain and set aside;

[0045] Add distilled water according to the weight ratio of material to liquid at 1:10, and beat with a beater;

[0046] The slurry after beating was placed in a colloid mill for homogenization to obtain a uniform tilapia fish skin slurry, which was pumped to a high-voltage pulsed electric field treatment chamber through a peristaltic pump at a flow rate of 8mL / min, with an electric field intensity of 25KV / cm and a pulse frequency of 30Hz The pulse time is 1s for processing to obtain the PEF treatment solution;

[0047] The obtained PEF treatment solution was treated at 121°C for 30 minutes to kill pathogenic bacteria, and then cooled to 35°C to obtain a liquid culture medium;

[0048] Inoculate the activated slant strain into the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com