Microparticle remover and removal method for high-humidity dew-formed exhaust gas

A micro-particle and remover technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of high maintenance cost, increased filter bag resistance, large equipment investment, etc., and achieve low processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

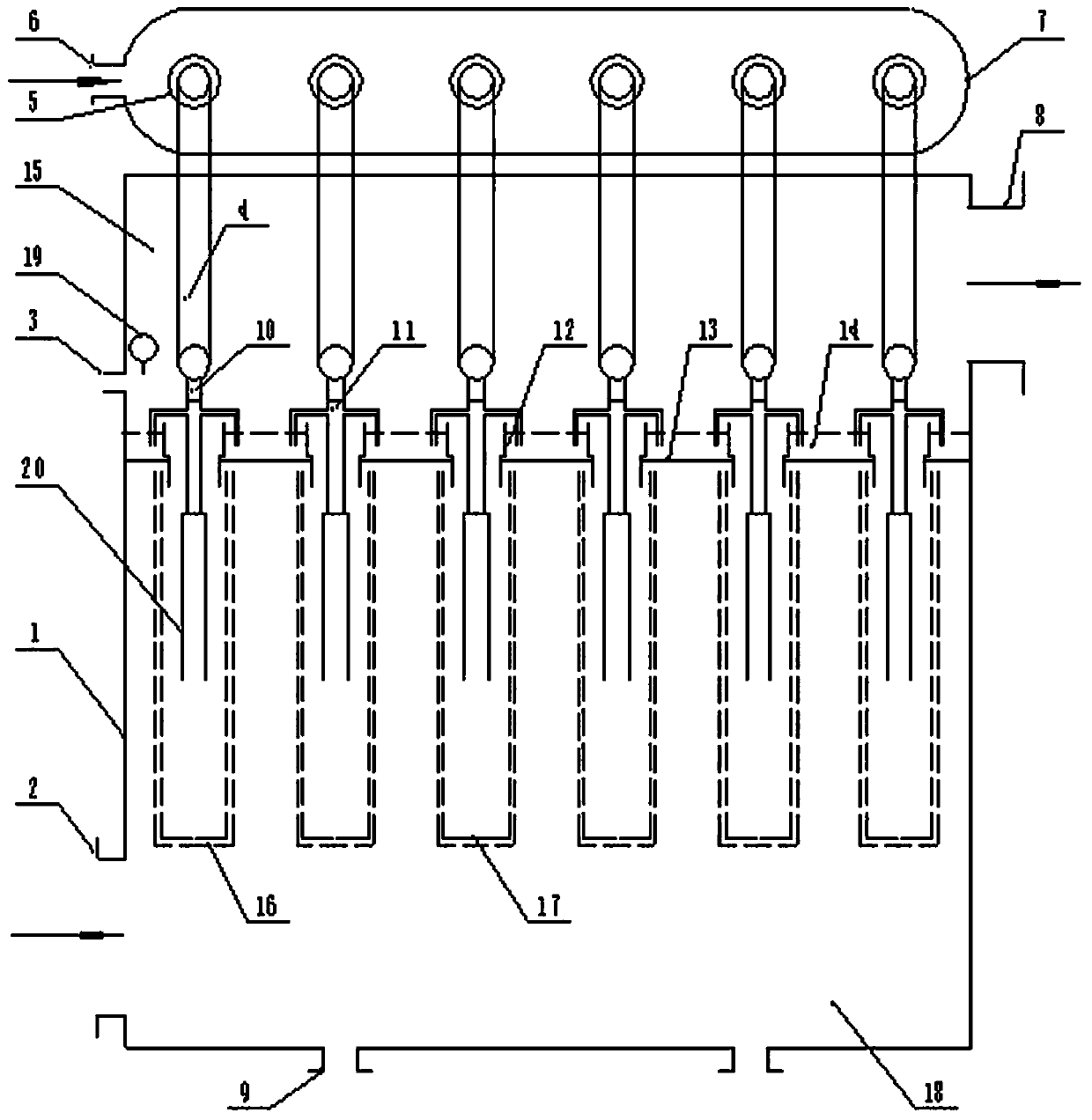

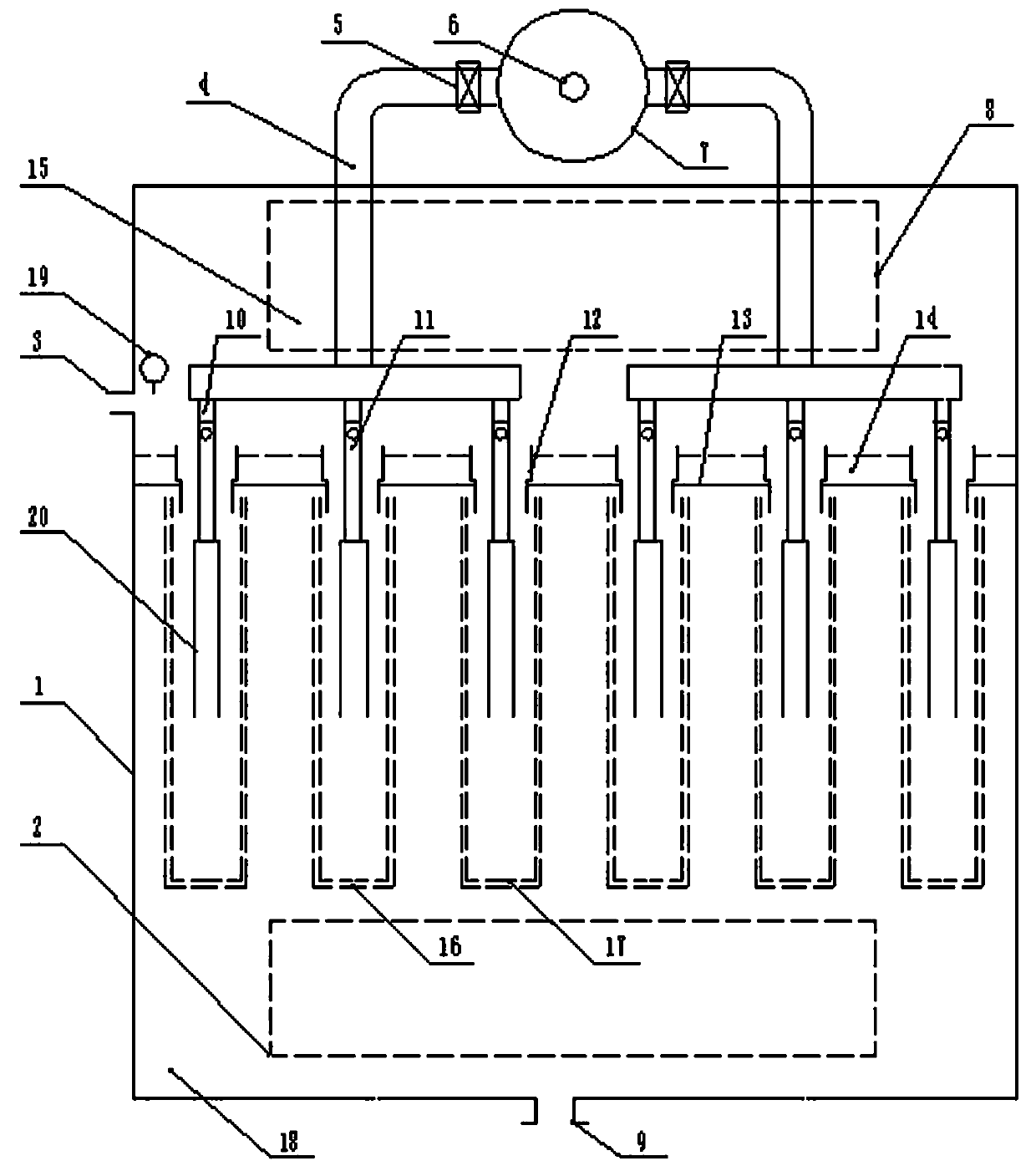

[0024] figure 1 and figure 2 Views of the internal structure in different directions for this patent application, such as figure 1 and figure 2 As shown, the housing 1 is included, and the housing 1 is provided with a clean air chamber 15 at the top and a lower air chamber 18 at the bottom of the clean air chamber 15. The lower air chamber 18 is provided with an air inlet 2, and the clean air chamber 15 is provided with a A partition 13 is arranged between the air port 8 , the lower air chamber 18 and the clean air chamber 15 .

[0025] The partition 13 is provided with a number of through holes, and the through holes are evenly arranged horizontally and vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com