Method for preparing nano silver particles with controllable grain size uniform size through seed growth method

A technology of nano-silver particles and particle size, which is applied in the direction of nanotechnology, can solve the problem of uncontrollable size of nano-silver particles, and achieve the effect of controllable size and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of nano-silver seeds with uniform particle size distribution around 5-8nm;

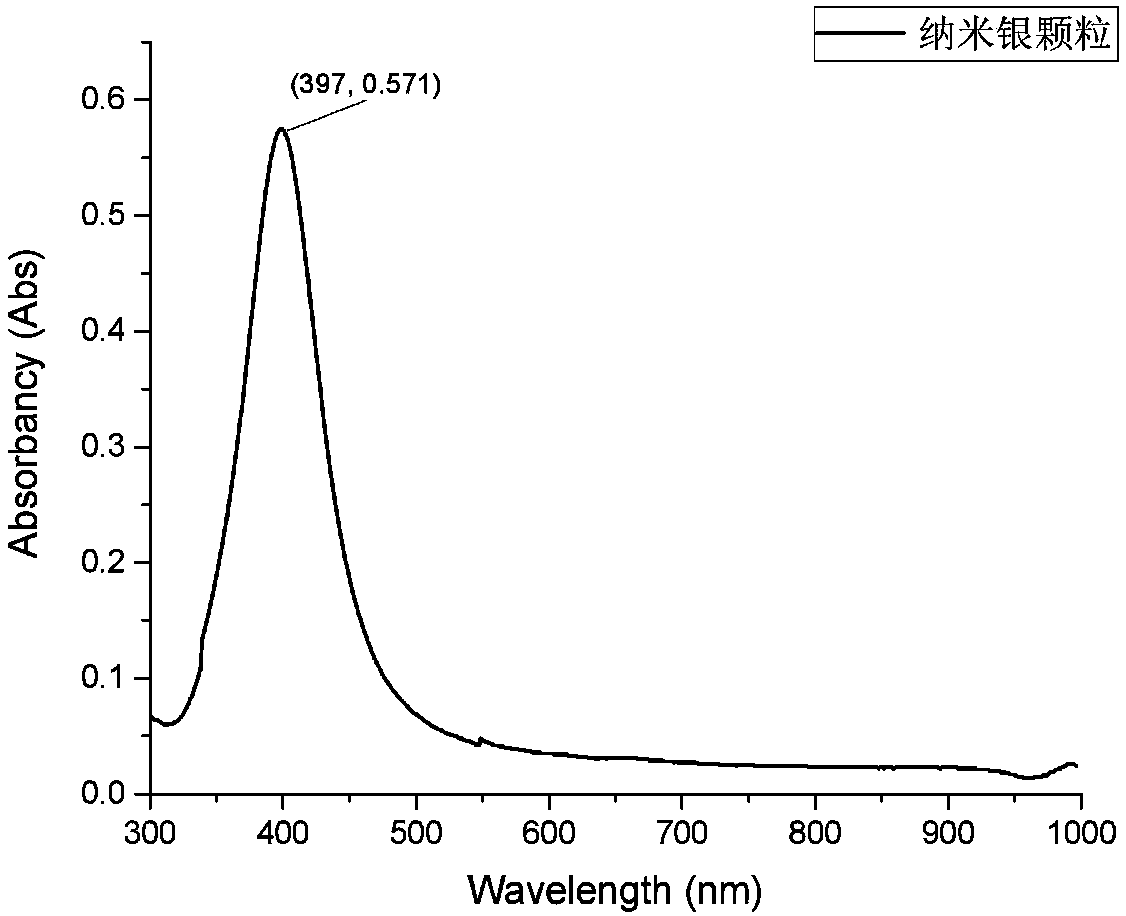

[0022] Add 1mL (2.5×10 3 mol / L) silver nitrate solution, then add 1.mL (0.01mol / L) mercaptoethanol, stir in an ice water bath and add 1.5mL (2.5×10 3 mol / L) sodium citrate, then add 0.16mL NaBH with a concentration of 0.1mol / L dropwise 4 , Stirring the reaction during the dropping process. After the reaction, the centrifuge tube containing the reaction solution is placed in a centrifuge at a temperature of 25°C. After centrifugation, the supernatant is removed, and the remaining liquid is the prepared nano silver particles after repeated washing with three-distilled water for 2-3 times. Its UV spectrum is as follows figure 1 As shown, its characteristic absorption peak is: 397nm, and its transmission electron microscope is as figure 2 Shown.

Embodiment 2

[0023] Example 2: Preparation of nano silver particles with uniform particle size distribution around 9-12 nm;

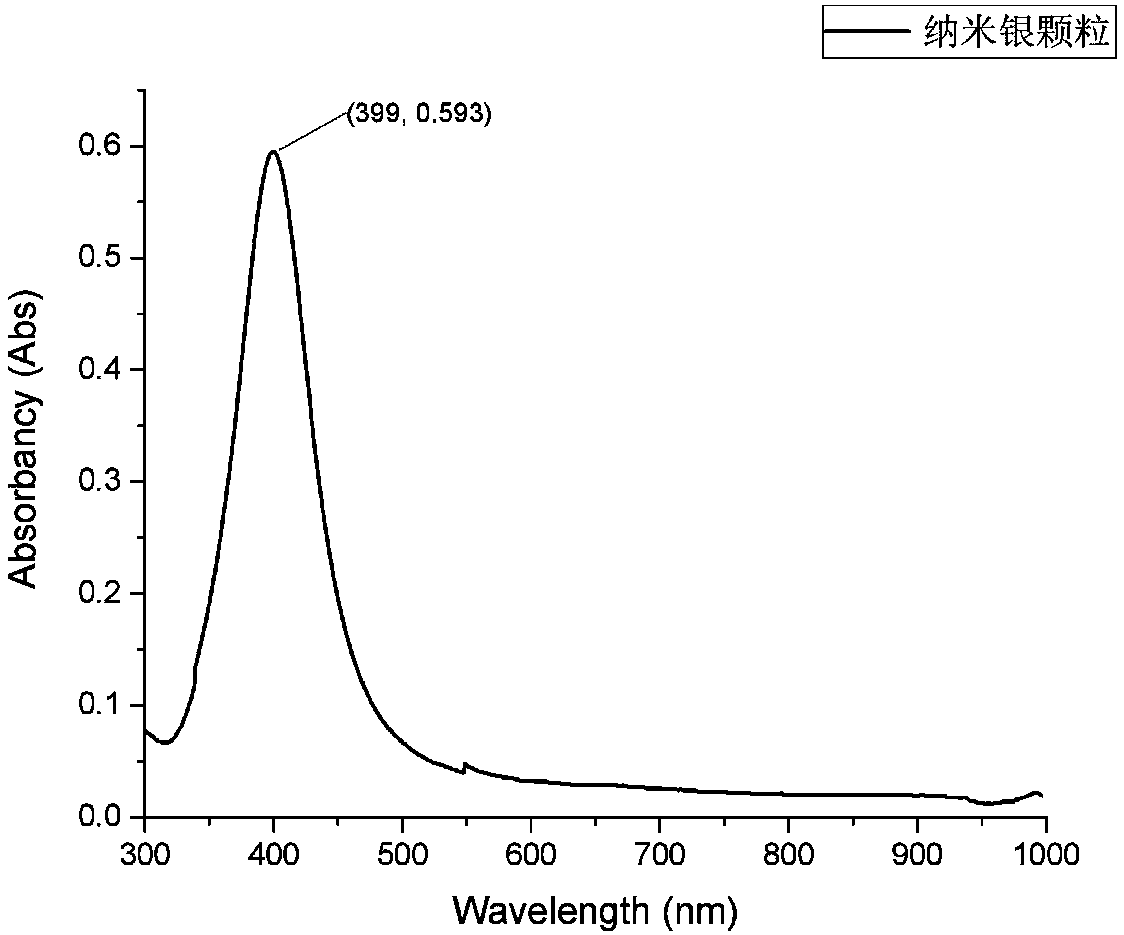

[0024] Add 2ml of the seed solution of Example 1 to a 25mL round-bottomed flask equipped with magnets and then add 1.5mL (2.5×10 3 mol / L) Silver nitrate solution is added dropwise to 0.18mL NaBH with a concentration of 0.1mol / L 4 , Stirring the reaction during the dropping process. After the reaction, the centrifuge tube containing the reaction solution is placed in a centrifuge at a temperature of 25°C. After centrifugation, the supernatant is removed, and the remaining liquid is the prepared nano silver particles after repeated washing with three-distilled water for 2-3 times. Its UV spectrum is as follows image 3 As shown, its characteristic absorption peak is 399nm.

Embodiment 3

[0025] Example 3: Preparation of nano silver particles with uniform particle size distribution around 13-16 nm;

[0026] Add 2ml of the seed solution of Example 1 into a 25mL round-bottomed flask equipped with magnets and then add 2mL (2.5×10 3 mol / L) Silver nitrate solution was added dropwise to 0.24mL NaBH with a concentration of 0.1mol / L 4 , Stirring the reaction during the dropping process. After the reaction, the centrifuge tube containing the reaction solution is placed in a centrifuge at a temperature of 25°C. After centrifugation, the supernatant is removed, and the remaining liquid is the prepared nano silver particles after repeated washing with three-distilled water for 2-3 times. Its UV spectrum is as follows Figure 4 As shown, the characteristic absorption peak is 401 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com