Galvanizing sink roll

A technology of sinking rolls and zinc liquid, which is applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of aggravated wear body, aggravated roll system vibration, and inability to eliminate roll marks, etc., to improve long-term stability performance, ensuring quality stability, and improving the effect of fragile defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

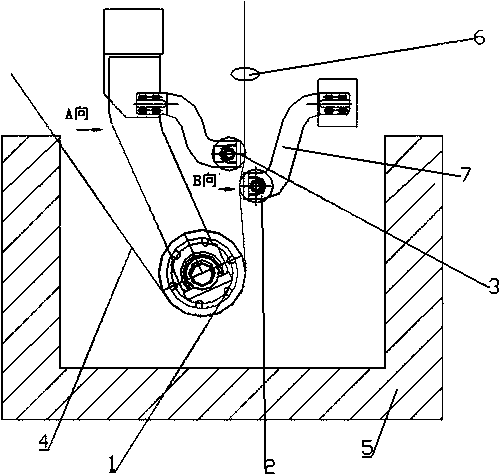

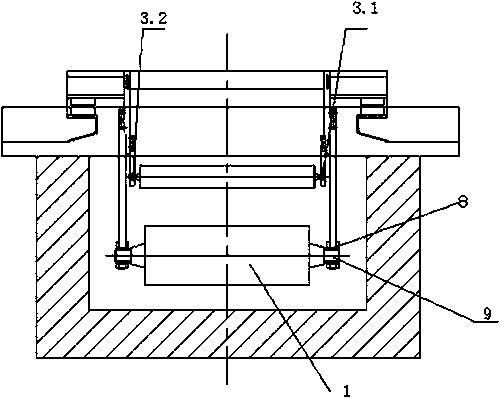

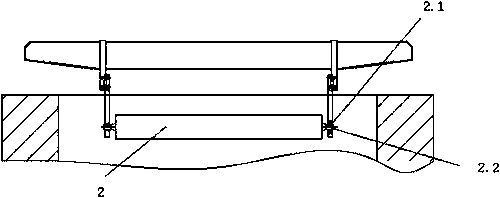

[0023] According to the galvanized sinking roll implemented in the present invention such as Figure 1-7 As shown, wherein, the galvanized sinking roller 1 is installed and set in the zinc pot 5 and lower than the zinc liquid level (as shown in the figure), and the metal strip is coated with zinc-containing metal; it is characterized in that: the metal strip 4 above the sinking roller 1 The direction of extension is also provided with stabilizing rollers 2 and positioning rollers 3 whose roller shafts are parallel to each other; the setting positions of the stabilizing rollers, positioning rollers and sinking rollers make: the metal strip 4 extends below the zinc liquid surface from the zinc pot and Located at the lowest point at the sinking roller 1, after contacting the sinking roller 1, it turns around the sinking roller 1 and extends upwards and is placed between the stabilizing roller 2 and the positioning roller 3. The metal belt can smoothly move between the stabilizing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com