Single impeller twin-stage blwor

A vortex air pump and single impeller technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of poor quality control, inconvenient processing, and cumulative errors, and achieve convenient processing, simple assembly, and reduced accumulation effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

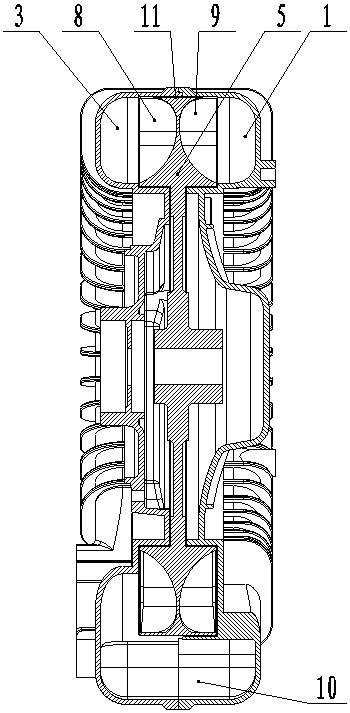

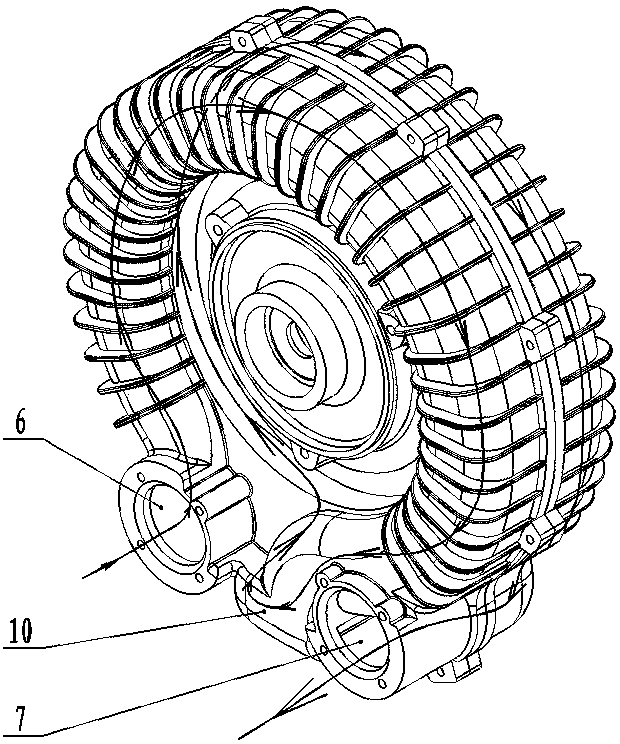

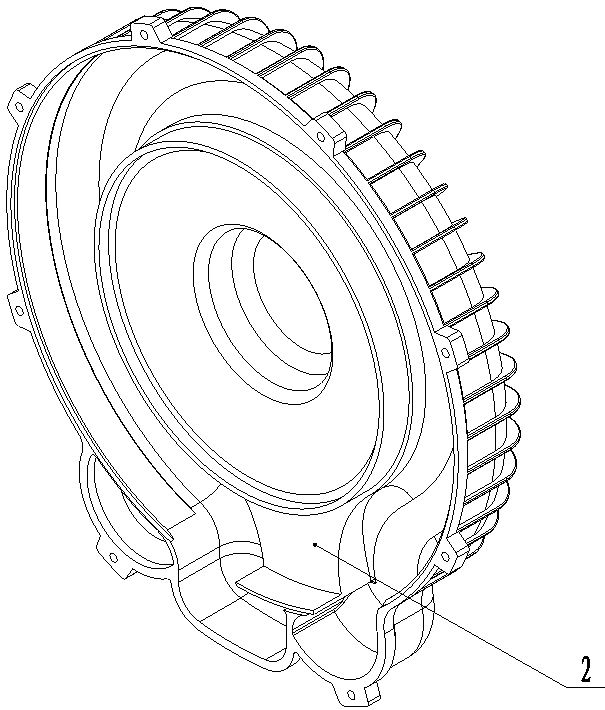

[0013] Figure 5 It is an example of a single impeller two-stage vortex air pump. When the impeller is driven to rotate by the prime mover, the transported fluid is driven by the working surface (8) behind the rotating impeller. figure 2 The air inlet (6) shown enters the rear flow channel (3) for the first pressurization, and the fluid flow generated by the rotation of the impeller presses Figure 5 The direction indicated by the solid line with the arrow in the center enters the bottom channel (10), and enters the front flow channel (1) through the bottom channel (10), and then the second time is driven by the rotation of the front working surface (9) of the impeller. supercharged, and figure 2 The shown air outlet flows out, thereby realizing the function of series supercharging. Compared with the two-stage vortex air pump in the prior art, the two parts of an impeller and a baffle are reduced, the volume is reduced by 15%, and the cost is reduced by 18%, thereby achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com