Acid dropping device, acid dropping machine table and making method of touch display screen

A technology of dripping acid and acid solution, which is applied in the input/output process of data processing, optics, instruments, etc., can solve the problems of dripping acid diffusion, reduce production costs, improve product yield, and solve the problem of dripping acid diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] Please refer to Image 6 , the first embodiment of the present invention provides an acid dropping device, which is used to perform acid drop etching on the metal conductive layer on the color filter substrate, so that the alignment mark covered by the metal conductive layer appears. The acid dripping device includes a motor 101 , an acid liquid storage tank 102 , a pipeline 103 , an acid dripping head 104 , a fluid replacement alarm sensor 106 , an acid injection port 107 and a sponge 108 .

[0038] The acid liquid storage tank 102 is used for supplying acid liquid to the acid dripping head 104, and the upper end of the acid liquid storage tank 102 is provided with a motor 101, and the lower end of the acid liquid storage tank 102 is provided with a pipeline 103, and the acid liquid storage tank 102 and the acid dripping head 104 Connected by the pipeline 103 , the motor 101 squeezes out the acid liquid from the acid liquid storage tank 102 and sends it to the acid dri...

no. 2 example

[0050] Please refer to Figure 10 , the acid drip device provided in the second embodiment of the present invention, including a motor 101 , an acid liquid storage tank 102 , an acid drip head 104 , a fluid replacement alarm sensor 106 , an acid injection port 107 and a sponge 108 . The main difference between this embodiment and the first embodiment above is that in this embodiment, the acid drip head 104 is directly installed with the acid liquid storage tank 102 to form a cylindrical structure, and the acid liquid storage tank 102 is located on the upper part of the cylindrical structure , The acid drip head 104 is located at the lower part of the cylindrical structure, thereby canceling the pipeline 103 connected between the acid liquid storage tank 102 and the acid drip head 104, the structure is simpler, and the use is easier. Wherein, the connection method between the acid drip head 104 and the acid liquid storage tank 102 can be threaded connection, buckle connection o...

no. 3 example

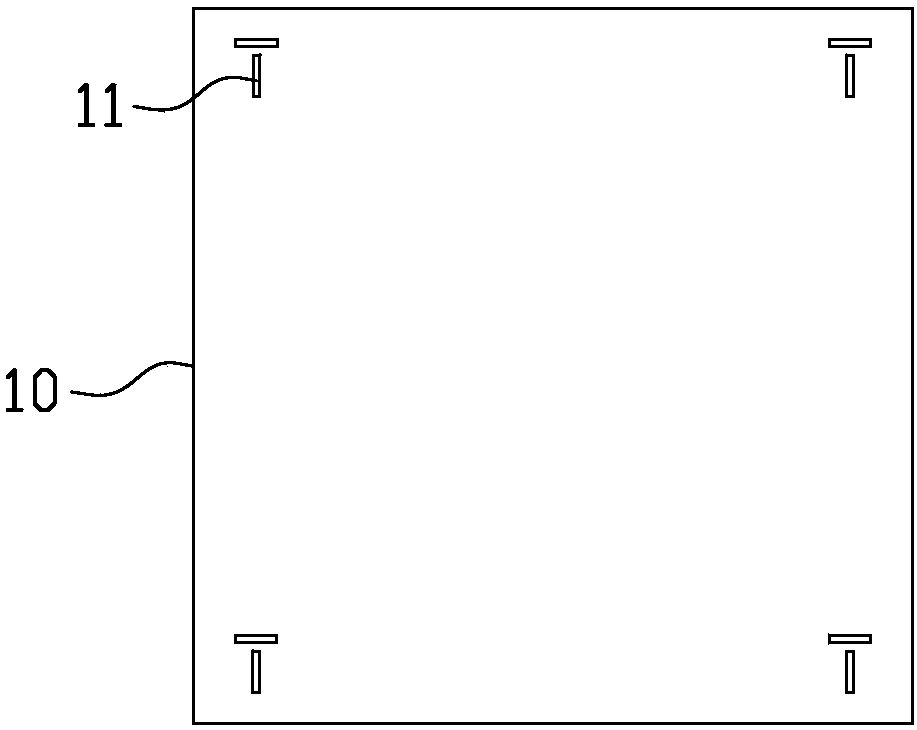

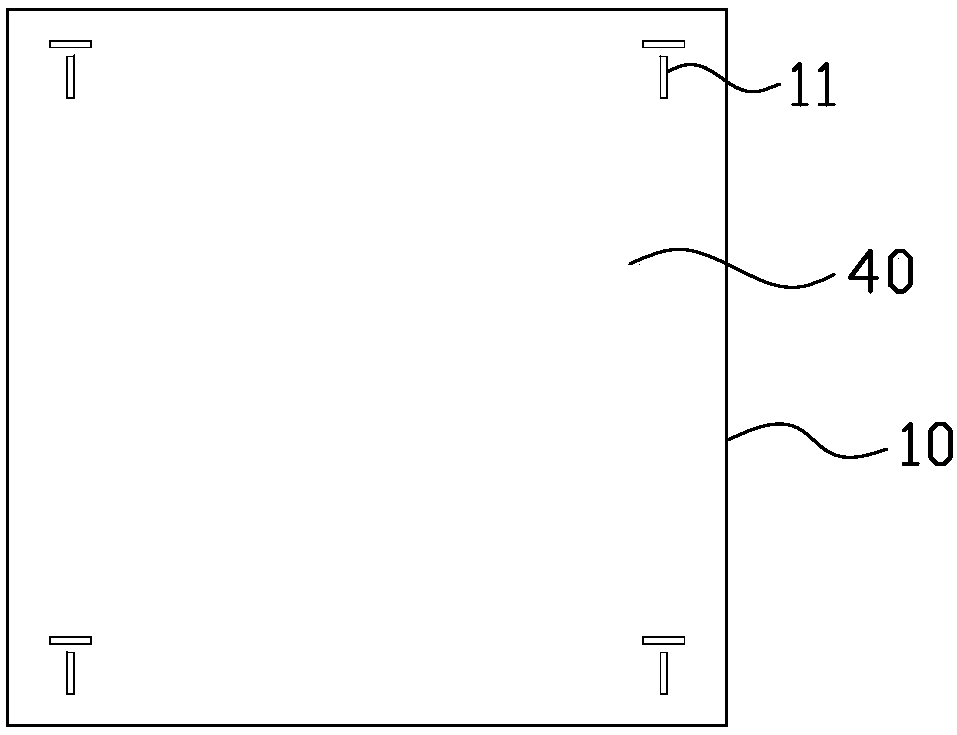

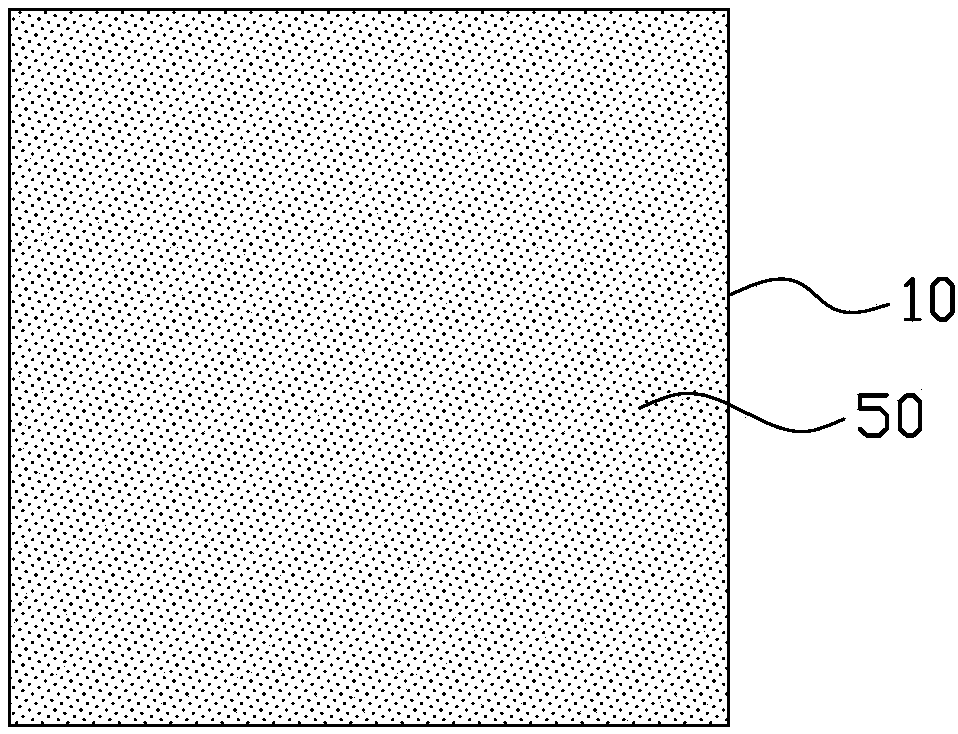

[0053] Please refer to Figure 11 , the acid dripping machine platform provided by the third embodiment of the present invention includes a platform 201 and a bracket 202 installed on the platform 201, the acid dripping device 100 is installed on the bracket 202, and one or more acid dripping devices 100 can be provided , the acid dripping device 100 can move forward and backward, left and right and up and down on the platform 201 and the support 202 . In this way, when the manufactured liquid crystal panel is placed on the platform 201, and the metal conductive layer 50 on the color filter substrate 10 is etched by the acid dropping device 100 so that the alignment mark 11 in the liquid crystal panel appears through the etching hole 51, it can pass through Moving the acid dripping device 100 aligns the sponge 108 of the acid dripping device 100 with the alignment mark 11, making the acid dripping accuracy more accurate and more intelligent.

[0054] In this embodiment, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com