Embedded-type touch control panel and preparation method thereof

A touch panel and embedded technology, applied in the field of embedded touch panel and its preparation, can solve the problems of mutual interference, weak anti-signal interference, low yield and the like, so as to prevent mutual signal interference and improve touch sensitivity. , the effect of simplification of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The method for manufacturing the above-mentioned embedded touch panel 10 according to one embodiment includes the following steps S110-S170.

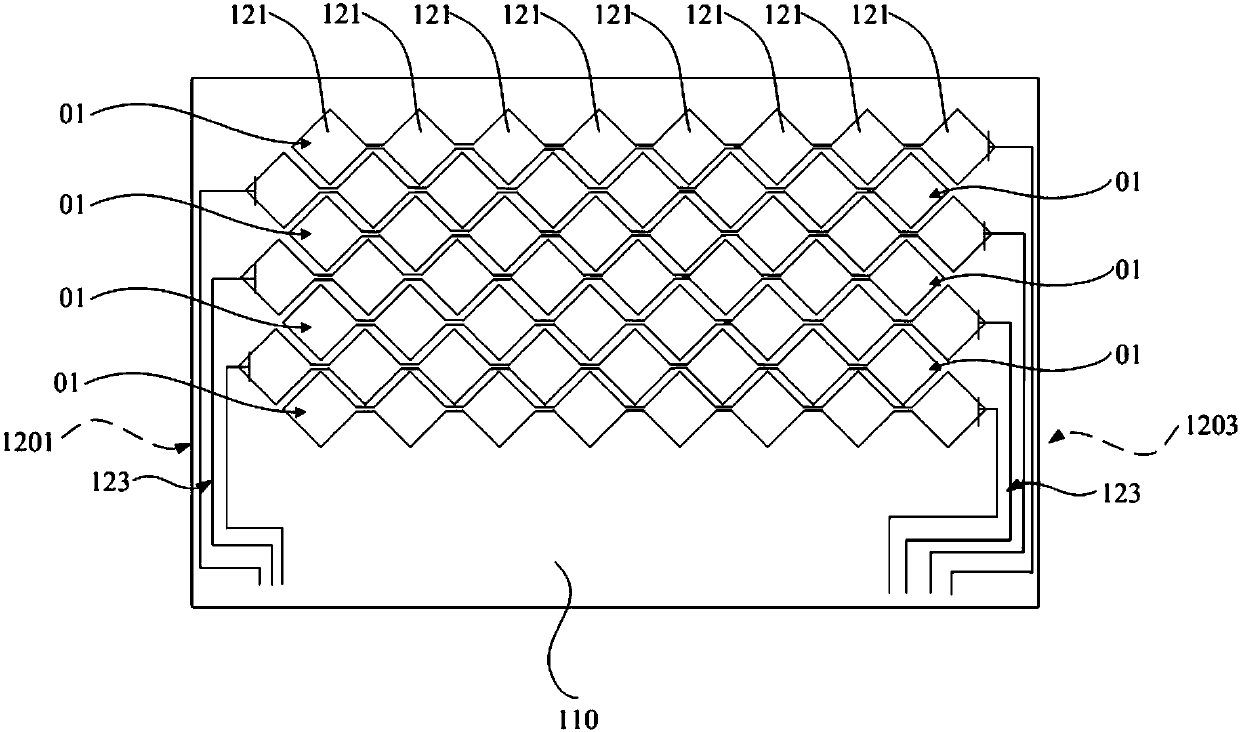

[0071] S110, forming a first electrode on the TFT display panel, the first electrode includes a plurality of first electrode blocks arranged in an array and first electrode leads electrically connected to the first electrode blocks.

[0072] Specifically, a layer of transparent conductive film can be obtained on the TFT display panel by magnetron sputtering or glue coating, and the thickness of the film is 900nm-1000nm. The raw material of the conductive film layer can be ITO, AZO or graphene. Graphene material is preferred if used for flexible panels. The first electrode block is formed by sequentially applying glue, photolithography, developing, etching, and peeling off the glue. Then the first electrode leads are formed by metal etching.

[0073] S120 , covering the first electrode with a polarizer to obtain a sensing compo...

Embodiment 1

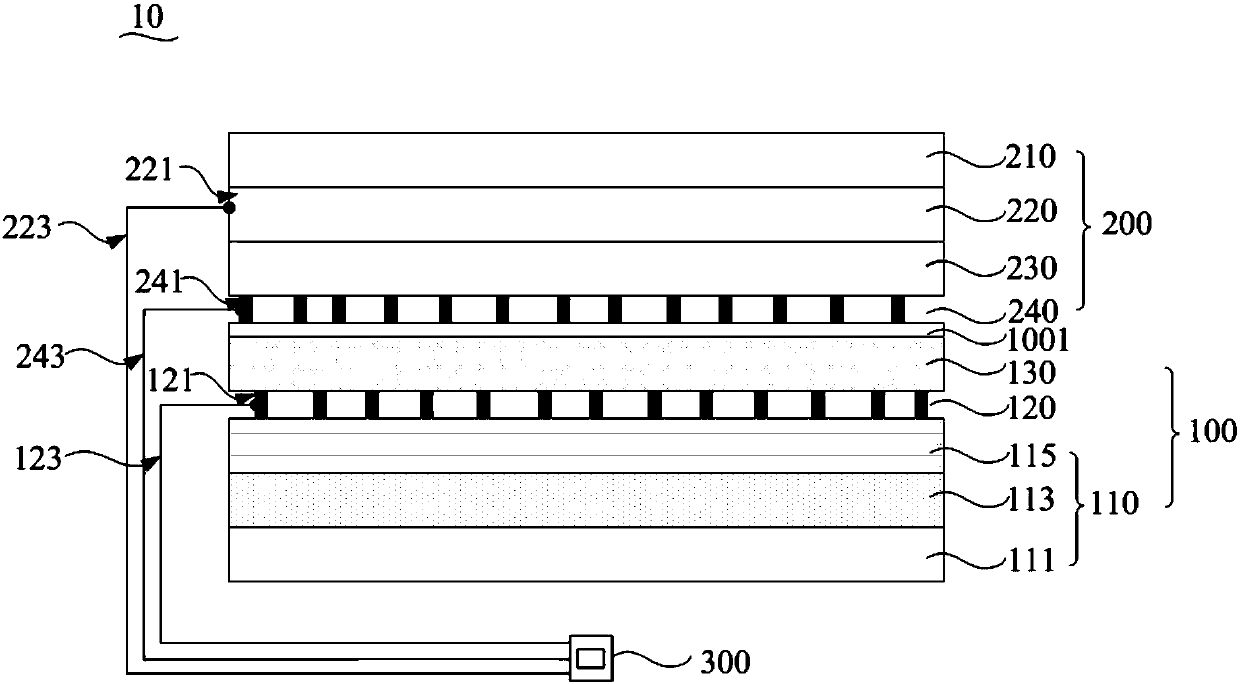

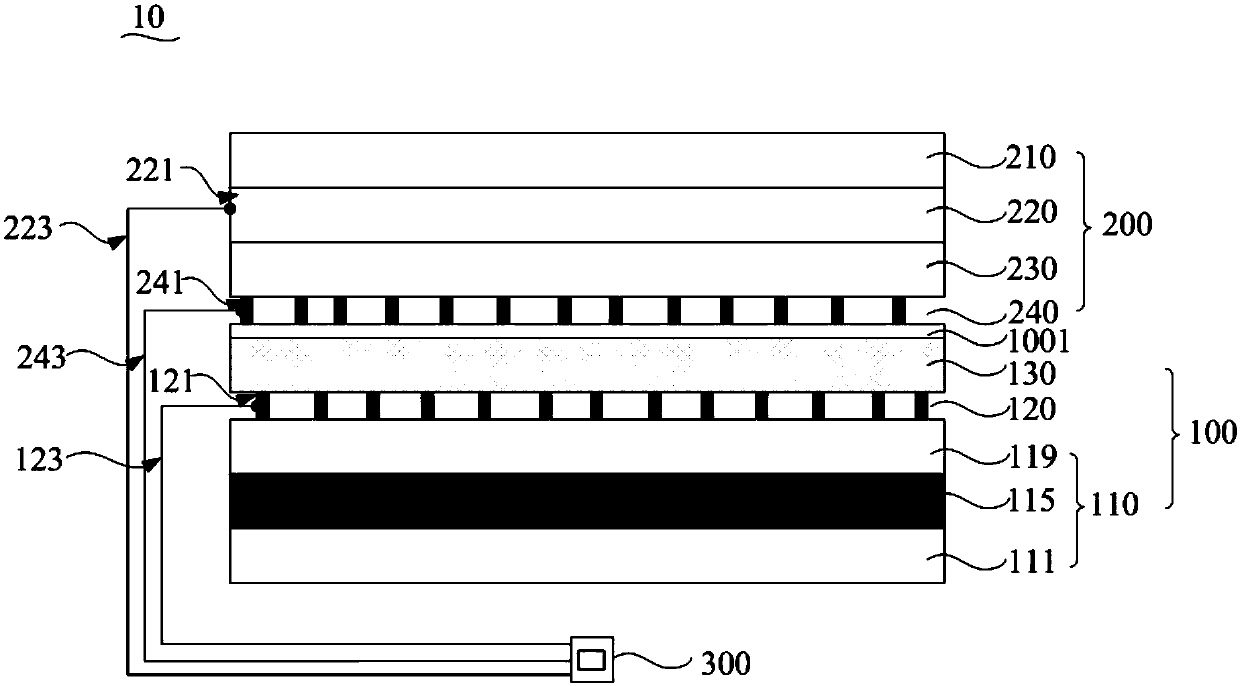

[0090] A TFT display panel is provided, and the TFT display panel includes a TFT substrate, a liquid crystal layer and a color filter stacked in sequence.

[0091] A layer of ITO transparent conductive film layer is formed on the color filter by magnetron sputtering method, and the thickness of the film layer is 950nm. On the transparent conductive film layer, a first electrode block is formed sequentially through glue coating, photolithography, development, etching, and glue stripping, and then a first electrode lead is formed through metal etching to obtain a first electrode. For the design of the first electrode see figure 2 shown. The surface resistance of the prepared first electrode was 33Ω, and the transmittance was 97%. A polarizer is covered on the first electrode to obtain a sensing component. Wherein the polarizer covers the surface of each first electrode block, and the polarizer covers the area of the surface of the TFT display panel not covered by the first...

Embodiment 2

[0099] (1) Preparation of induction components

[0100] A TFT display panel is provided, and the TFT display panel includes a TFT substrate, a liquid crystal layer and a color filter stacked in sequence.

[0101] A layer of AZO transparent conductive film is formed on the color filter by magnetron sputtering method, and the film thickness is 900nm. On the transparent conductive film layer, a first electrode block is formed sequentially through glue coating, photolithography, development, etching, and glue stripping, and then a first electrode lead is formed through metal etching to obtain a first electrode. For the design of the first electrode see figure 2 shown. The surface resistance of the prepared first electrode was 30Ω, and the transmittance was 98%. A polarizer is covered on the first electrode to obtain a sensing component. Wherein the polarizer covers the surface of each first electrode block, and the polarizer covers the area of the surface of the TFT display...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com