Control method of electronic equipment charging cabinet

A control method and technology of electronic equipment, applied in the direction of electric vehicle charging technology, battery circuit device, arrangement of multiple synchronous batteries, etc., can solve charging cabinet charging, need people to guard, etc., to achieve automatic operation and intelligent storage Take and realize the effect of centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

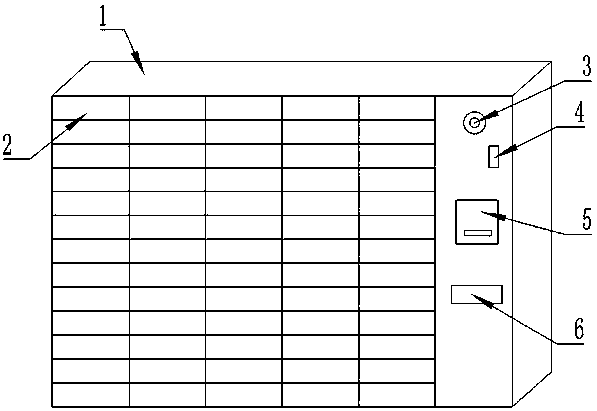

Embodiment 1

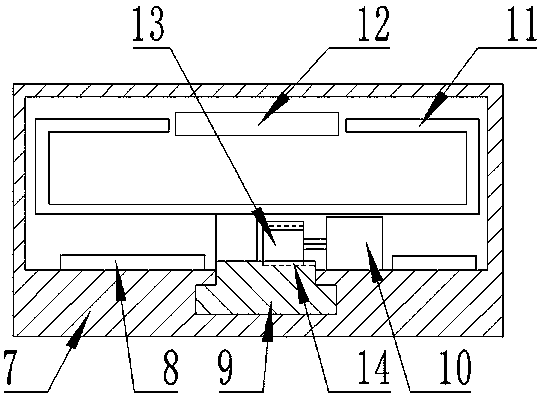

[0039] On the basis of the above embodiments, the present invention discloses a preferred embodiment of an electronic equipment charging cabinet. The pressing mechanism includes a connecting head 17 and an engaging block 21. One end of the connecting head 17 is connected to the pressing plate 12. The other end of the head 17 is provided with an engaging tooth 24; the connecting head 17 has a shaft hole; the engaging block 21 is arranged on the slot 11, and the engaging block 21 is provided with an upper engaging groove 22, a lower engaging groove 23, and an upper engaging groove 22 Separated from the lower engagement groove 23 by smooth protrusions; the engagement tooth 24 can be engaged with the upper engagement groove 22 or the lower engagement groove 23; the pressing mechanism includes a rotating shaft 18, which passes through the rotating shaft hole, and is connected to Dowel 19, dowel 19 links to each other with slot 11 by back-moving spring 20; When cooperating with the ...

Embodiment 2

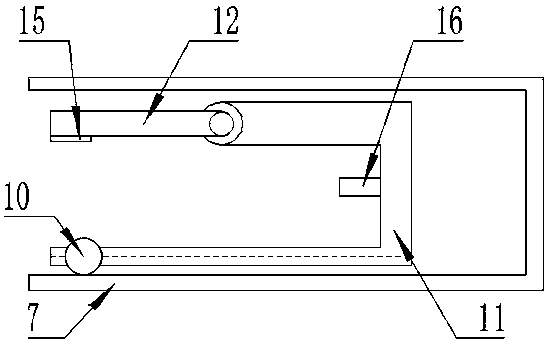

[0042] On the basis of embodiment 1, a chute is provided on the charging tank 7, and the slide rail 9 is matched with the chute, and the slide rail 9 can move in the chute, and the slide rail 9 is provided with a rack 14; 7 is provided with a driving motor 10, the rotating shaft of the driving motor 10 is connected with a gear 13, the gear 13 is meshed with the rack 14, the driving motor 10 can drive the slide rail 9 to move through the gear 13; the pressing plate 12 is provided with a cushion 15. The control circuit includes a central control unit and a motor drive circuit, and the central control unit is electrically connected to the drive motor 10 through the motor drive circuit.

[0043] When the slot 11 pops up, the central control unit controls the drive motor 10 to rotate in the forward direction through the motor drive circuit, and the drive motor 10 drives the gear 13 to rotate, and the gear 13 meshes with the rack 14 to convert the rotation into a linear drive. In th...

Embodiment 3

[0045] On the basis of Embodiment 1 or 2, the interface of the charging plug 16 includes a Micro USB interface, a USB Type C interface and a Lightning interface; the charging grid 2 matches the charging slot 7, and the charging grid 2 on the charging cabinet 1 has specifications of Various, can accommodate electronic devices of different sizes and structures for charging.

[0046] The charging circuit can provide electric energy for the electronic equipment, and the central control unit can adjust the charging mode and the charging current according to the type of the electronic equipment and the input equipment, so as to achieve the maximum charging effect and ensure the charging efficiency. Micro USB interface, USB Type C interface and Lightning interface include most of the charging interface ports of electronic devices on the market, greatly improving the scope of services. The charging connector is replaced according to the change of the interface. Customers can basicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com