Soldering flux spraying device and using method thereof

A spraying device and flux technology, applied in spraying devices, auxiliary devices, spray booths, etc., can solve problems such as the inability to effectively control the thickness of the powder layer, the large volume of the powder spraying system, and the inability to meet the spraying requirements, etc., to achieve pollution-free operation , reduce the amount of dust, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, features and effects of the flux spraying device and method of use proposed according to the present invention are described in detail below.

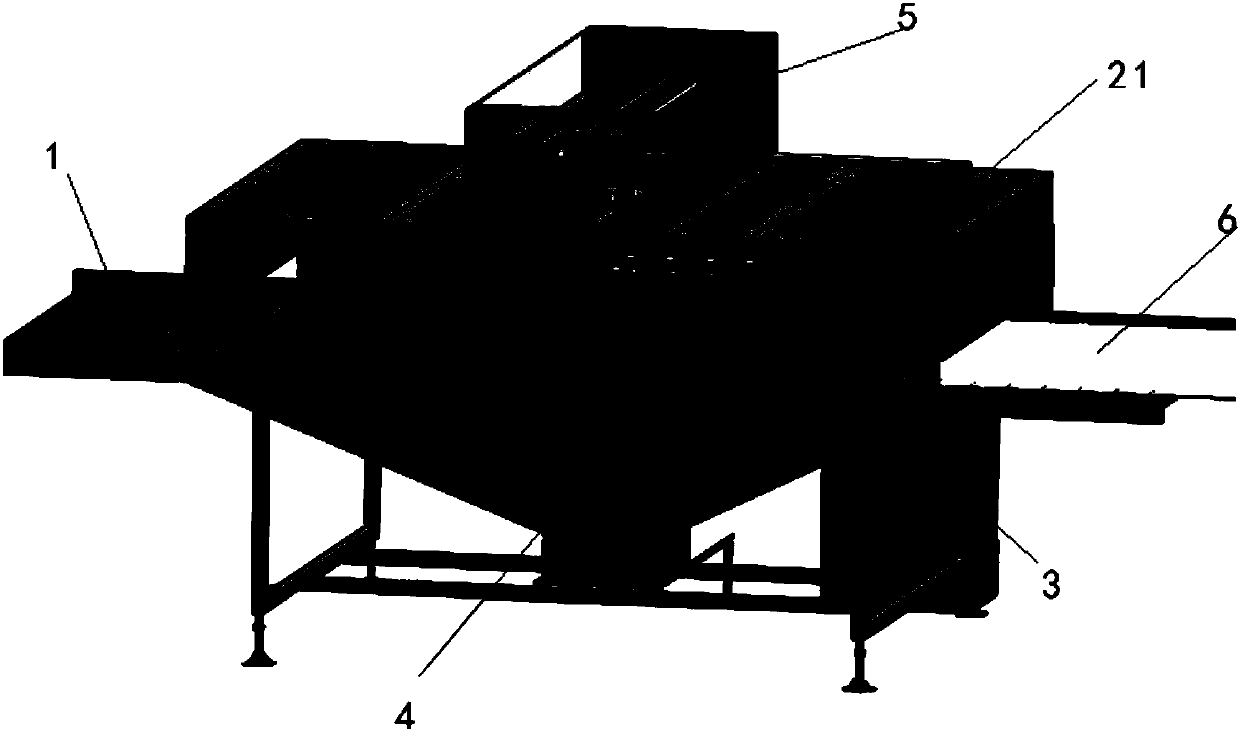

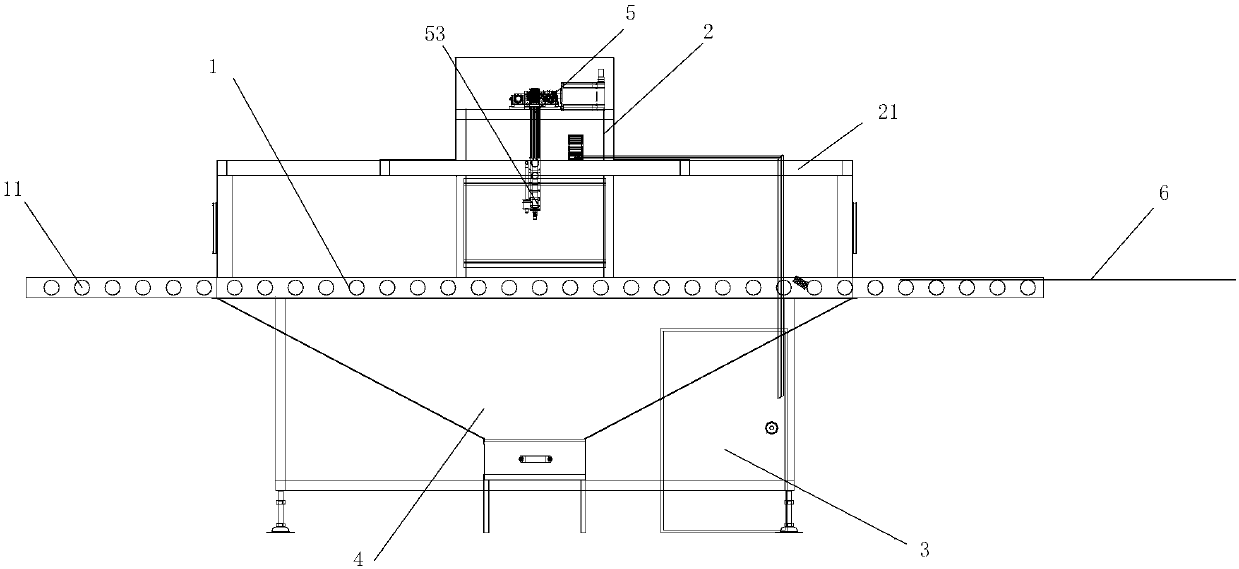

[0033] Such as Figure 1-2 As shown, the invention discloses a flux spraying device, comprising:

[0034] The conveying system 1 is used to convey the plate 6 to be sprayed in the horizontal direction, and the bottom of the conveying system 1 is provided with a uniform gap, and the setting of the gap is convenient for the powder recovery system 4 to recover the flux powder that has not been sprayed on the plate 6;

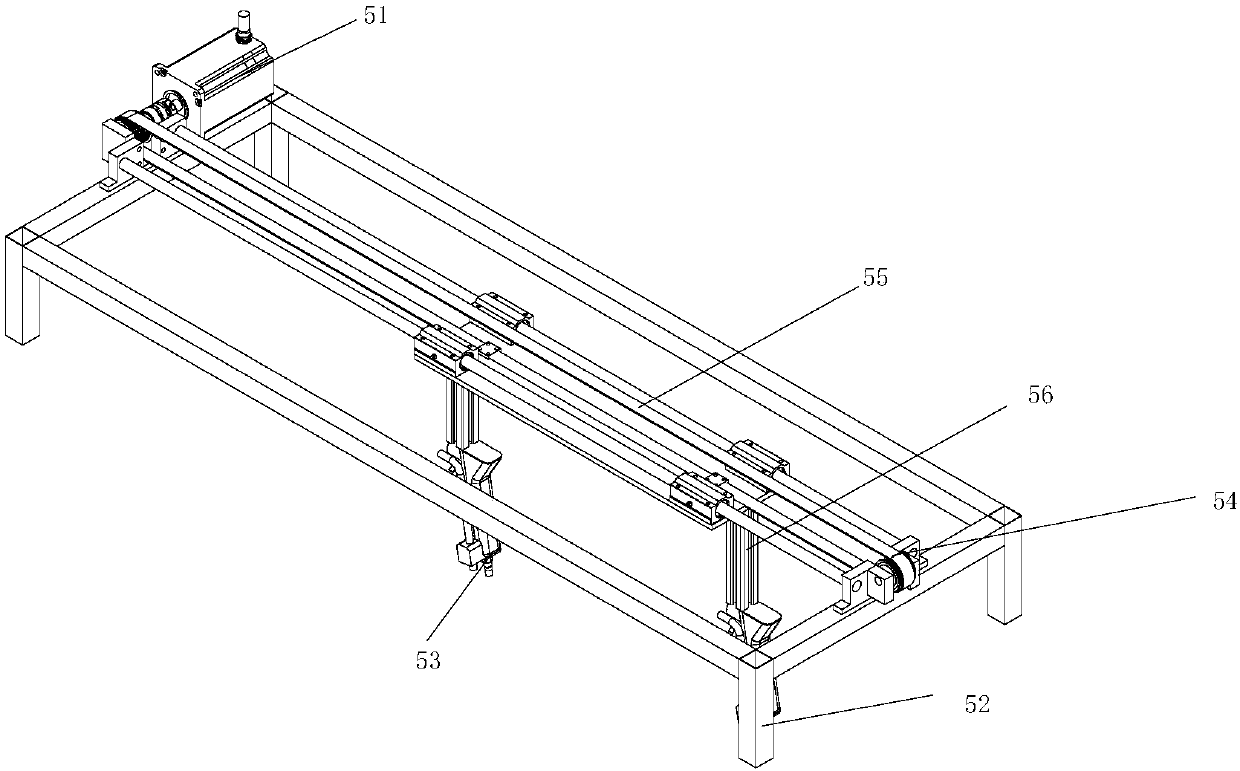

[0035] The spraying system 2 includes an outer frame main body 21 and a spray gun 53 arranged inside the outer frame main body 21, wherein the outer frame main body 21 is fixedly arranged on the upper part of the conveying system 1 to form an upper cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com