Display module separation device and separation method

A display module and separation device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of expensive LCD display screen, broken organic display screen, and low repair yield rate, so as to improve repair Yield rate and material utilization rate, the effect of improving cutting accuracy and yield rate, and increasing the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

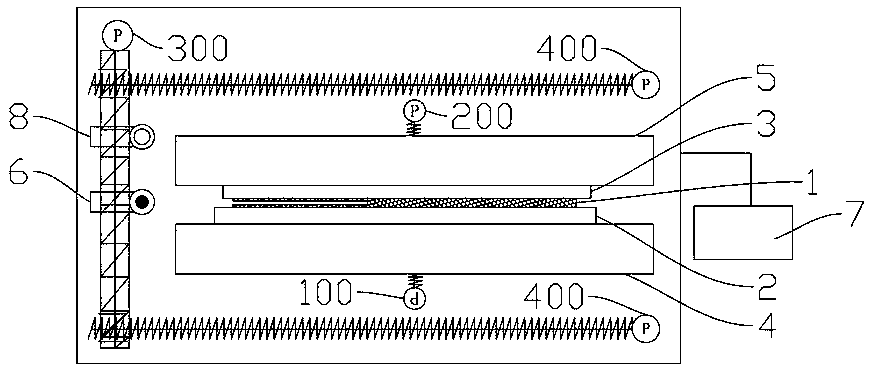

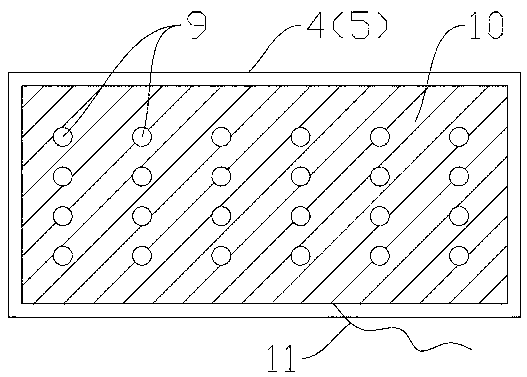

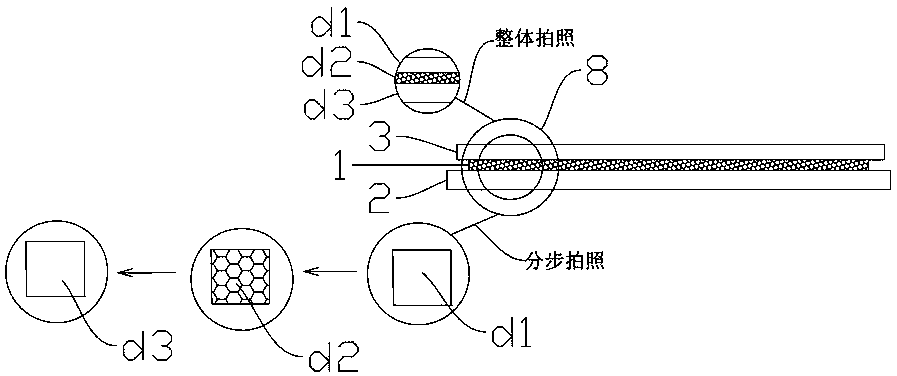

Embodiment 1

[0031] Such as figure 1 As shown, this embodiment provides a display module separation device for separating the first part 2 and the second part 3 bonded by the adhesive layer 1 on the display module. The separation device mainly includes a first fixing platform 4 , the second fixed platform 5, the laser cutting mechanism 6 and the control mechanism 7, the first fixed platform 4 and the second fixed platform 5 are parallel and oppositely arranged, and the display module is arranged between the first fixed platform 4 and the second fixed platform 5 , the first part 2 is fixed to the first fixing platform 4 , the second part 3 is fixed to the second fixing platform 5 , and the laser cutting mechanism 6 cuts the adhesive layer 1 to separate the first part 2 and the second part 3 . Laser cutting the adhesive layer 1 to separate the first part 2 and the second part 3, only exerting force on the adhesive layer 1 during cutting, avoiding the cracking of the first part 2 and / or the s...

Embodiment 2

[0043] A separation method of the display module separation device according to Embodiment 1, comprising the following steps:

[0044] S1. Fixing: Place the first part 2 and the second part 3 pasted by the adhesive layer 1 between the first fixing platform 4 and the second fixing platform 5, and the control mechanism 7 controls the first part 2 to be fixed on the first On the fixed platform 4, control the second component 3 to be fixed on the second fixed platform 5;

[0045] S2, forming a pulling force in the opposite direction: the control mechanism 7 controls the first fixed platform 4 to form a pulling force on the first component 2, and controls the second fixed platform 5 to form a pulling force on the second component 3, so that the first component 2 and The second parts 3 are all in a tensioned state;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com