Copper wire annealing and cooling device

A cooling device and annealing technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of inability to cool the copper wire, short contact time between the copper wire and the cooling liquid, etc., achieve good cooling, eliminate tissue defects, reduce deformation and The effect of crack tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

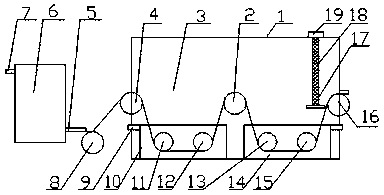

[0017] Example: see Figure 1-2 , a copper wire annealing cooling device, including a cooling device body 1, the cooling device body 1 includes a preheating furnace 6 and a cooling box 3, one side of the preheating furnace 6 is provided with a wire inlet 7, the preheating furnace The other side of the furnace 6 is provided with a wire outlet 5, the lower end of the wire outlet 5 is equipped with a first wire inlet wheel 8, and the two sides of the cooling box 3 are respectively equipped with a second wire inlet wheel 4 and an outlet wire wheel 16. A first cooling box 10 and a second cooling box 14 are installed in the box 3, and one end of the first cooling box 10 and the second cooling box 14 is provided with a liquid inlet 9, and a second cooling box 10 is installed in the first cooling box 10. A cooling wheel 11 and a second cooling wheel 12 , and a third cooling wheel 13 and a fourth cooling wheel 15 are installed in the second cooling box 14 .

[0018] The upper end betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com