Production technology of high wearproof warp-binding formed net

A production process and forming net technology, applied in the cutting of textile materials, weaving, fabrics, etc., can solve the problem of small contact area of wear-resistant surface, etc., and achieve the effect of improving service life, stable use and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

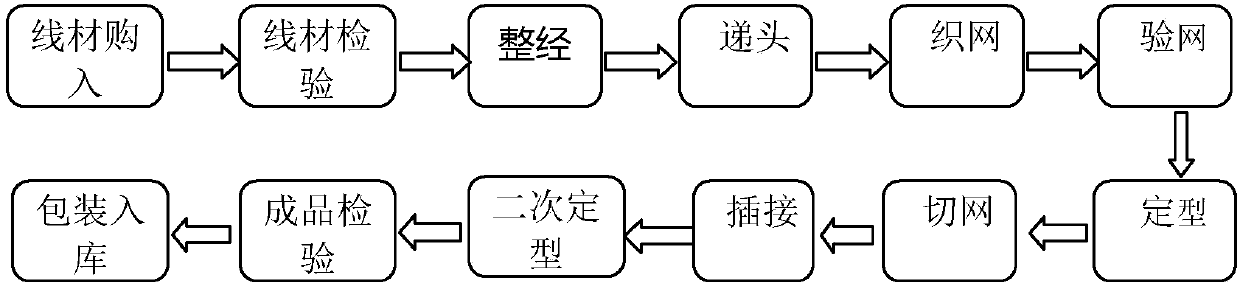

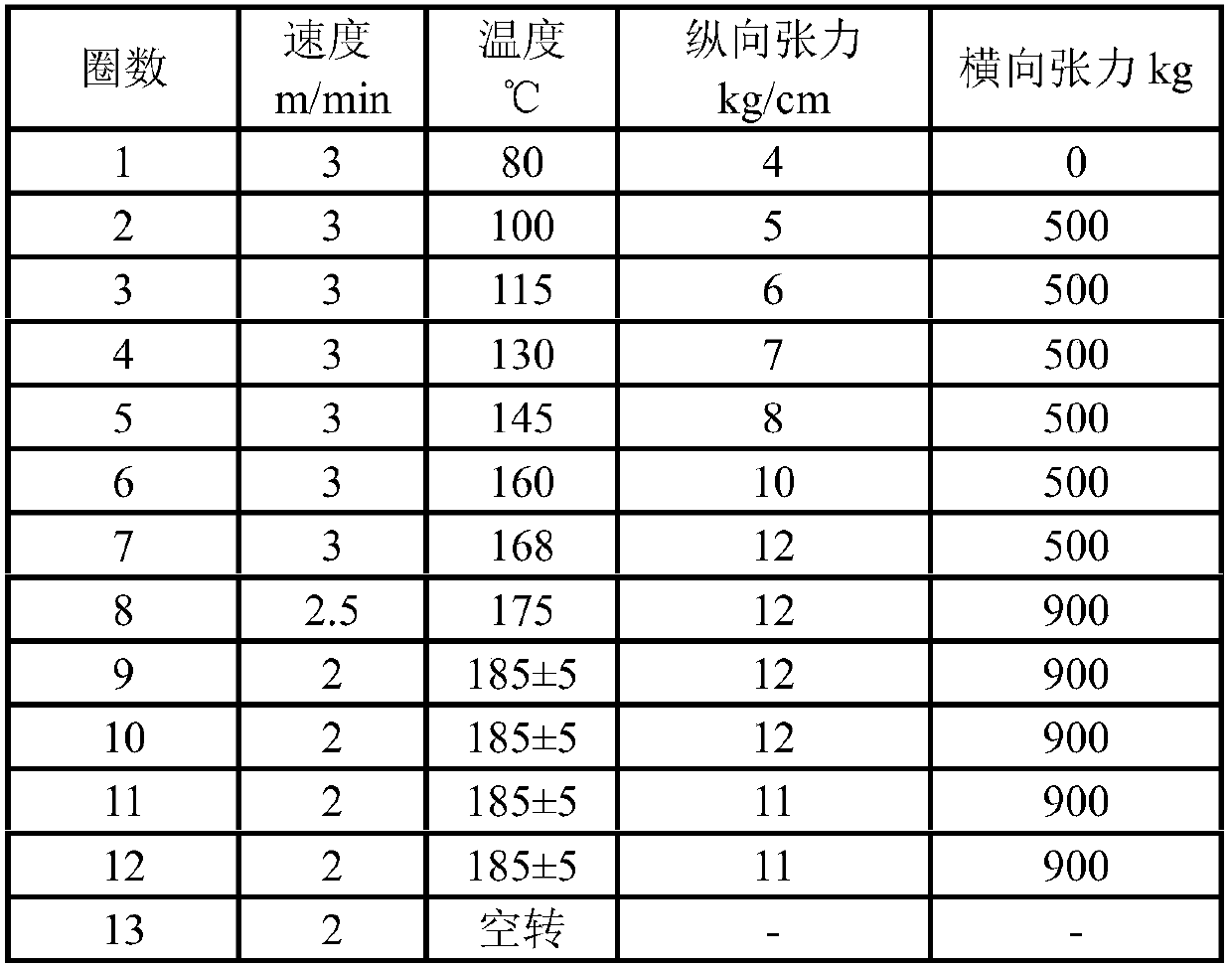

[0051] A production process of a high wear-resistant bonded forming net, comprising the following steps:

[0052] (1) Purchase of raw materials

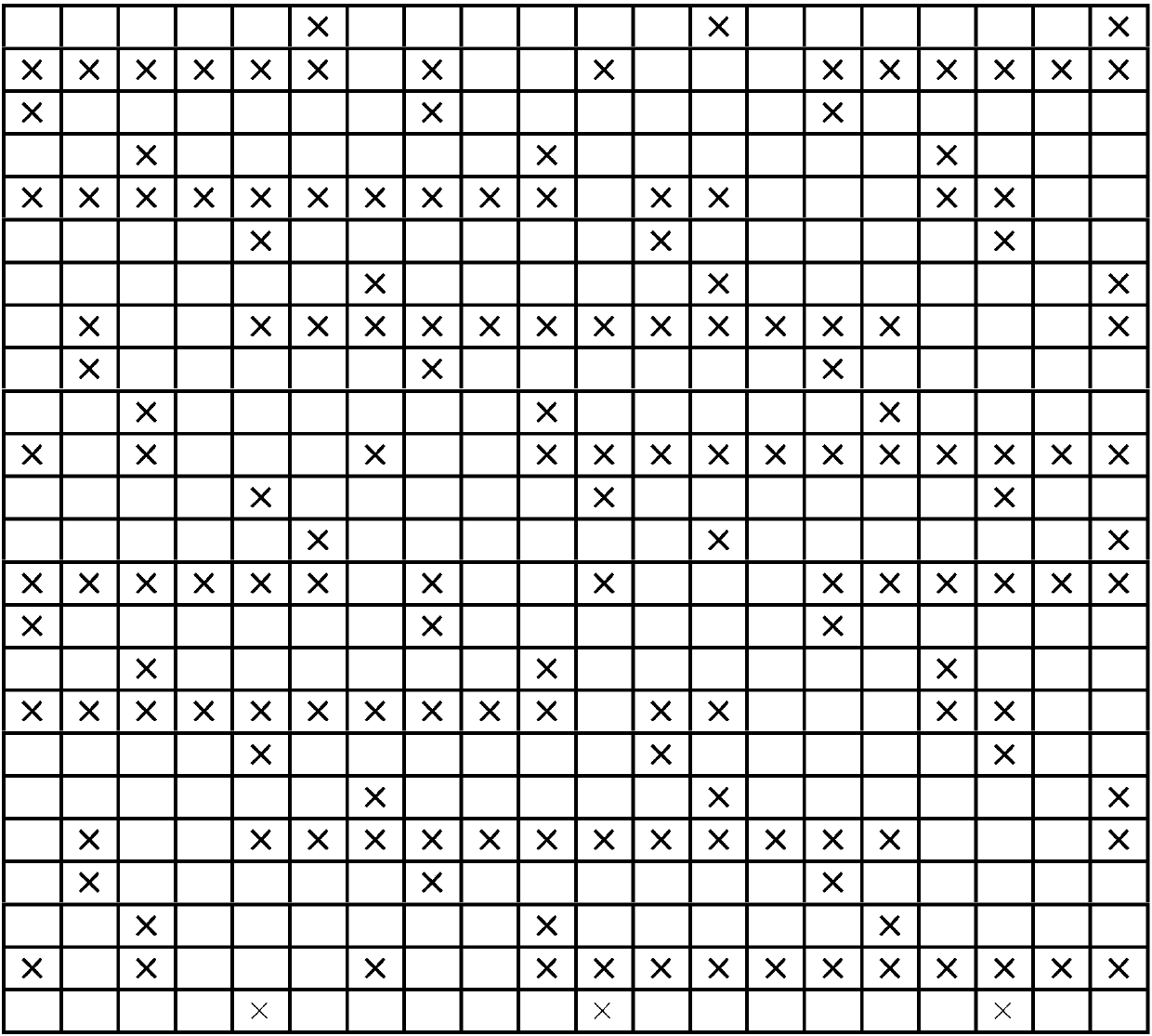

[0053] According to the product design and production plan, the surface warp and independent binding warp are made of high-strength polyester monofilament, and the bottom warp is made of high-wear-resistant nylon monofilament; all weft threads are made of high-strength polyester monofilament;

[0054] (2) Wire inspection

[0055] According to the product design and production plan, the size, heat shrinkage, tensile strength, acid and alkali resistance, and wear resistance performance indicators of the purchased monofilament are inspected one by one. Wear performance parameters are tested by suppliers, raw materials and finished products. The wire inspection standards are as follows:

[0056] Surface warp: Φ(0.18-0.23)mm±0.005mm, tensile strength: ≥600N / mm 2 , Dry heat shrinkage value: 10%-16%;

[0057] Binding warp: Φ(0.18-0.23)m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com