Light conversion material packaging structure, backlight module and display device

A technology of light conversion materials and packaging structures, applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased cost of diaphragms, expensive barrier films, complex processes, etc., and achieve the effect of reducing usage and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

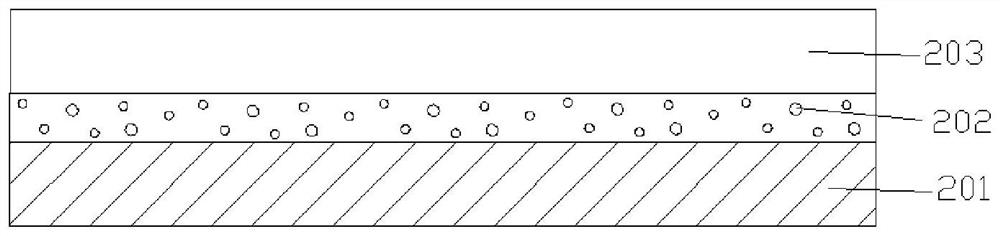

[0027] see figure 2 , in the embodiment of the light conversion material encapsulation structure of the present invention, the light conversion material 202 of the light conversion material encapsulation structure is coated on the diffusion plate 201, and the light conversion material 202 is also covered with a barrier layer 203. In this implementation In an example, the barrier layer may be PET (polyethylene terephthalate, polyethylene terephthalate PET barrier film), or contain materials such as silicon oxide and titanium oxide. Because the light conversion material 202 is generally sensitive to water vapor and oxygen, and is prone to failure during use, the barrier layer 203 is used to cover the light conversion mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com