Rapid and high-precision correction method for beam path of electron accelerator

An electron accelerator and high-precision technology, applied in the direction of instruments, adaptive control, control/adjustment systems, etc., can solve problems such as difficulty, and achieve safety, high practical applicability and reliability, accuracy and speed sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

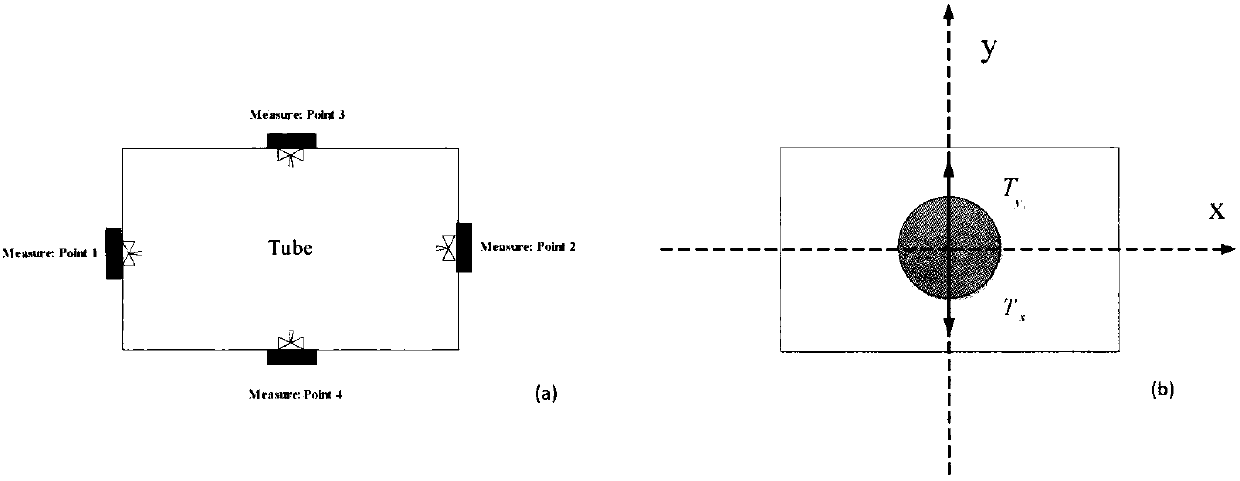

[0011] The present invention designs a detection method based on dual sensor information fusion, which is used to quickly prepare and detect the beam path. The schematic diagram of the structure layout is as follows figure 1 shown. Install a beam probe on the inner wall of the beam pipe to detect the beam intensity at the four walls of the beam pipe, and install a high-precision digital temperature sensor on the outer wall of the beam pipe to detect the temperature of the four walls of the beam pipe. The real-time displacement of the beam is obtained by the average weighting algorithm.

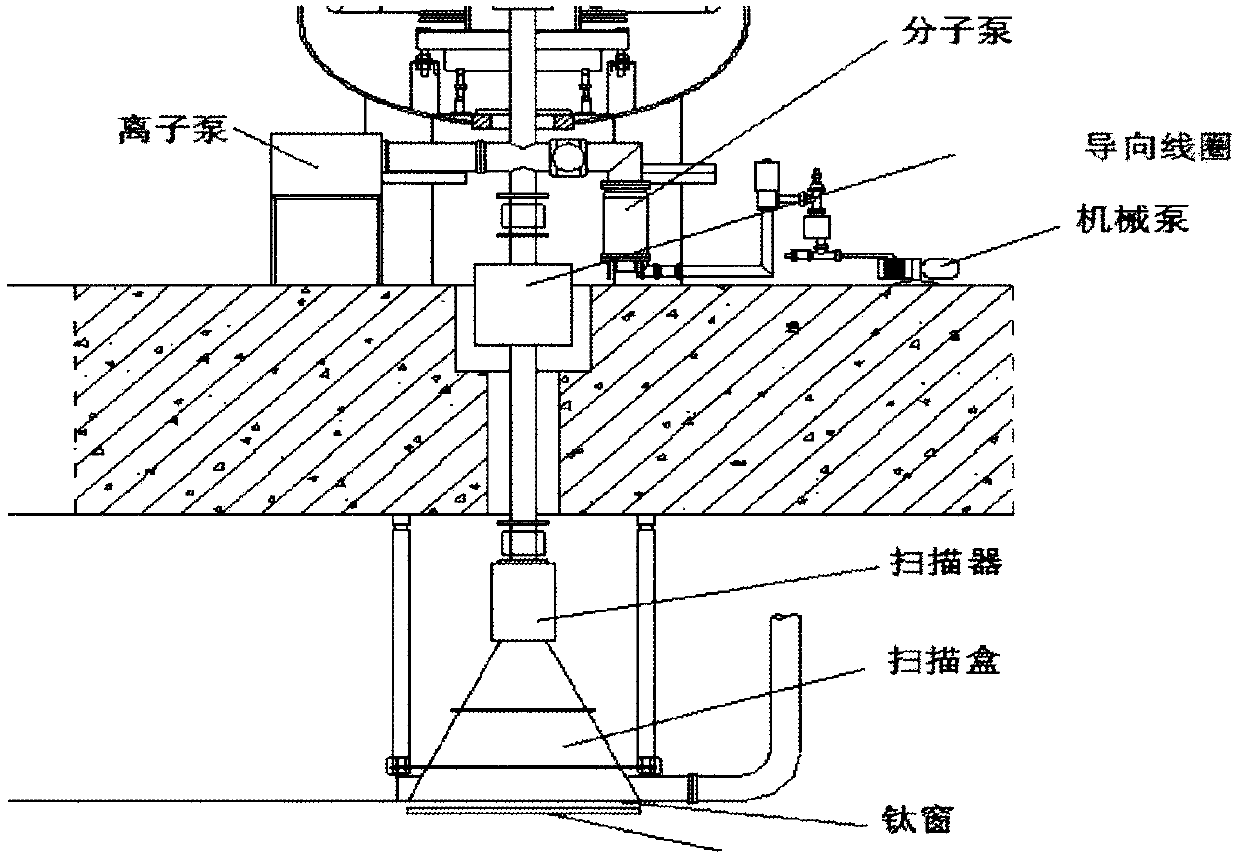

[0012] The structure diagram of the non-contact electron beam current control system designed by the present invention is as follows: figure 2 As shown, the guide coil is installed outside the beam pipe, and the special triangular wave excitation power supplies power to the scanning magnet. By controlling the alternating current of the two-dimensional steering coil, the magnetic field gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com