High voltage prevention high frequency transformer

A high-voltage, high-frequency, transformer technology, applied in the field of transformers, can solve problems such as affecting normal work, uneven placement of transformers, and difficulty in operation, so as to avoid potential safety hazards, improve production efficiency, and avoid fixed methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention will be further described below with reference to the accompanying drawings and in combination with specific embodiments, so that those skilled in the art can implement it by referring to the description, and the protection scope of the present invention is not limited to the specific embodiments.

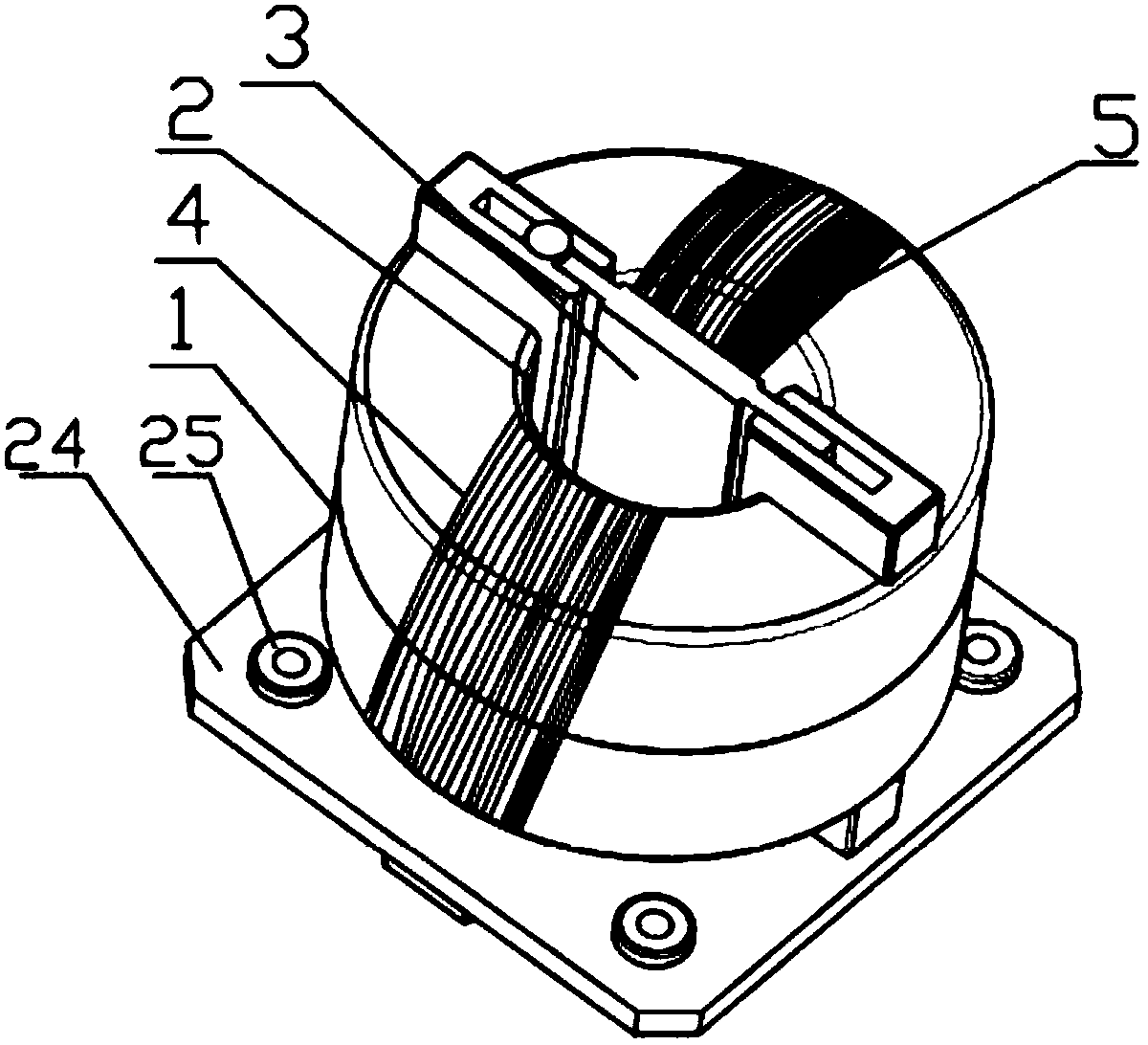

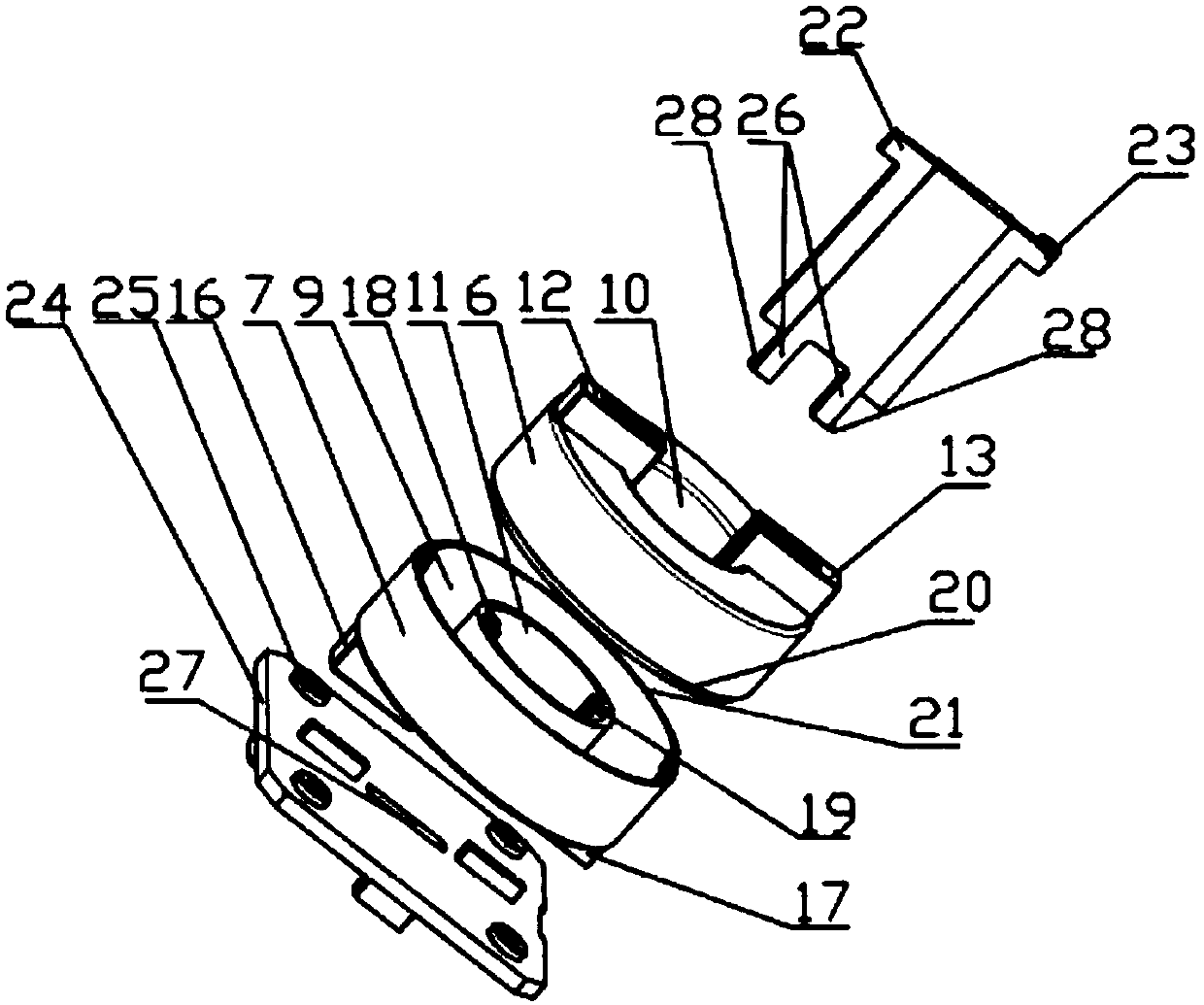

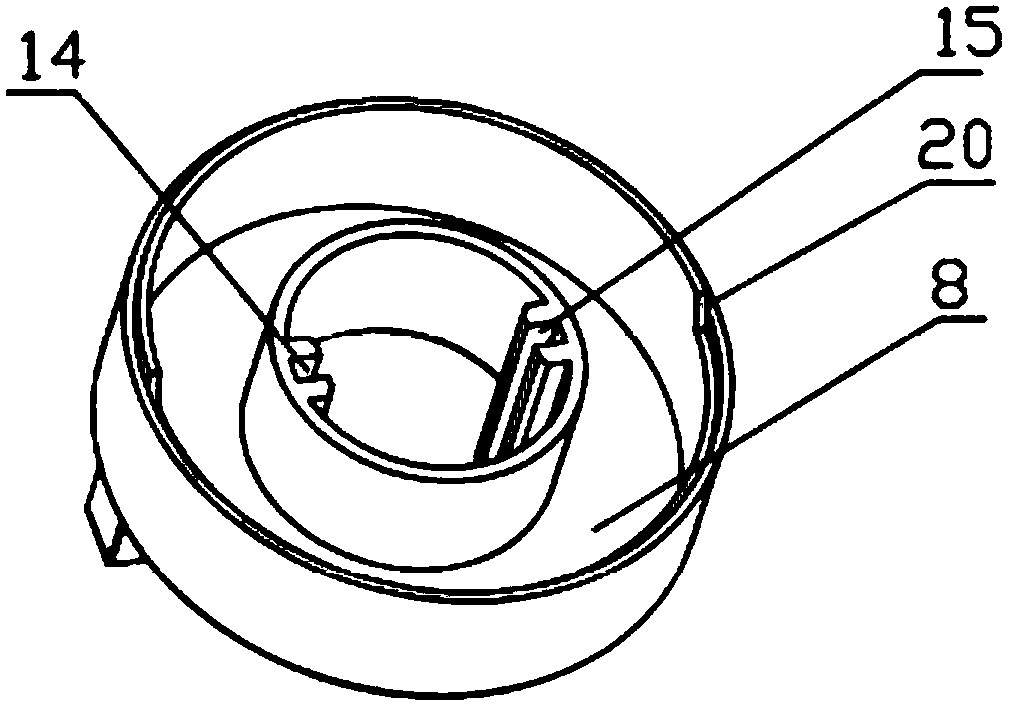

[0019] The invention relates to an anti-high voltage and high frequency transformer, such as figure 1 As shown, it includes a casing 1 and a ring through hole 2 arranged on the vertical center axis of the casing. The inside of the casing 1 includes an inner cavity for placing a magnetic ring. The movable insert 3 of the hole 2, the primary winding 4 located on one side of the insert and wound on the shell 1, and the secondary winding 5 located on the other side of the insert 3 and wound on the shell 1, the lead-out end of the winding Enter from one opening of the ring through hole 2 and exit from the other opening, and the winding is wound on the shell 1 round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com